European Flexible Packaging Market Trends Analysis: Regulations and Innovation Drive Sustainable Development

On September 2, the latest data published by Towards Packaging showed that the global flexible packaging market is expected to increase from USD 323.25 billion in 2025 to USD 488.72 billion in 2034, with a compound annual growth rate (CAGR) of 4.7% throughout the forecast period from 2025 to 2034.

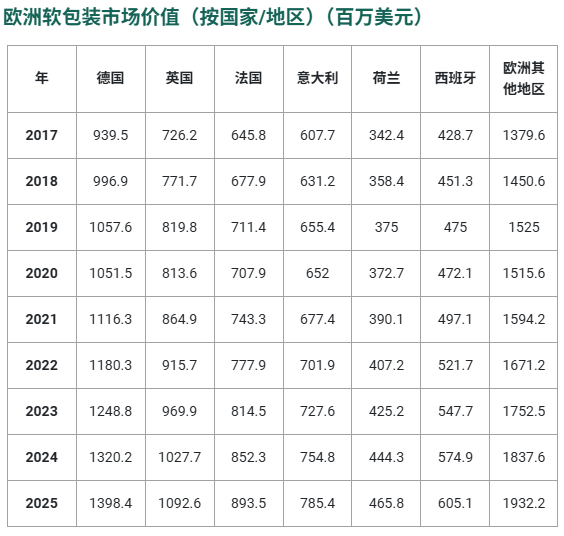

Meanwhile, the European flexible packaging market is undergoing profound transformation, driven by environmental regulations, consumer preferences, and regional differences, moving towards greater sustainability and efficiency.

PART.01

Policies and regulations reshape the industry landscape.

The EU Packaging and Packaging Waste Regulation (PPWR) will come into effect in February 2025, requiring a 5% reduction in per capita packaging waste by 2030 and 10% by 2035, as well as mandating that the recyclability rate of packaging materials be increased to 55%. It promotes MDOPE/GRSPE (containing recycled materials) to become mainstream, whose barrier performance is close to traditional composite materials and is compatible with various formats such as stand-up pouches and flat pouches.

In addition, starting from 2030, the use of single-use plastic packaging for fruits and vegetables weighing less than 1.5 kilograms will be prohibited, forcing companies to switch to compostable materials such as wood pulp-based cellulose film and PLA metallized film. These materials can fully degrade within 12 months under industrial composting conditions.

The Circular Economy for Flexible Packaging (CEFLEX) in Europe strongly recommends that flexible packaging use single polyethylene (PE) material (with a weight proportion exceeding 90%), with other barrier components allowed to contain a maximum of 5% by weight.

PART.02

Consumer Perception and Behavioral Differentiation

According to surveys, 44% of European consumers believe that reducing food waste is key to lowering environmental impact, but only 50% of consumers recognize that soft packaging is easy to recycle (65% in Spain, 40% in Germany).

This cognitive difference leads to divergence in regional market strategies: Southern European countries focus on promoting recyclable packaging, while Northern Europe places greater emphasis on the application of bio-based materials.

For example, a Spanish dairy company adopted a 23μm cellulose metallized film customized by Kaifeng, reducing the carbon footprint by 32%; a German pet food packaging switched to microwaveable PLA film, increasing the repurchase rate by 18%.

PART.03

Regional Market Dynamics and Competitive Landscape

As the largest consumer in Europe (accounting for 19%), leading companies such as Amcor and Mondi have strengthened their advantages in aluminum-plastic composite technology through acquisitions, such as Constantia's acquisition of Aluflexpack.

Exports account for 33%, attracting companies like Sudpack to set up factories. In 2024, flexible packaging production is expected to grow by 12%, with a focus on developing PE/PP single-material production lines.

Due to the impact of the Plastic Packaging Tax (PPT), the usage rate of recycled plastics increased to 35% in 2024. 3D Neopac launched tubes with a 23% reduction in thickness, resulting in an 18% decrease in costs.

PART.04

Challenges and Future Prospects

Despite some progress, the current European flexible packaging sector faces bottlenecks such as insufficient recycling infrastructure (only 50% is recyclable) and high costs for bio-based materials (20-30% more expensive than petroleum-based ones). Achieving a true circular economy remains a long-term goal, as continuous recycling and reuse of materials are still needed, but market trends are clear:

E-commerce drives lightweighting.

The European food industry, particularly in snacks, ready-to-eat foods, and frozen foods, relies on flexible packaging to extend shelf life and seek portability. For example, the demand for frozen food bags is increasing by 8% annually, requiring resistance to low temperatures of -20°C and an oxygen barrier of less than 5 cm³/m²·day.

2 Circular Economy Closed Loop

Rukai Peak has collaborated with Unilever to launch carbon footprint labels, achieving full traceability from raw materials to recycling. The bioplastics market share is expected to reach 25% by 2030.

The European flexible packaging market is accelerating its transformation towards high recyclability, low environmental impact, and high added value, driven by policy enforcement, technological breakthroughs, and consumption upgrades. It is expected to become the "core testing ground" for global green packaging innovation over the next five years.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track