EOS Finally Launches 1-Meter Size Metal 3D Printer! Equipped with 8 Units of 1-Kilowatt Lasers, AMCM New System

Introduction:In the field of LPBF metal 3D printing equipment, domestic manufacturers have already produced printers with a forming size of 2 meters, while leading foreign companies like EOS have been producing equipment with a forming size of up to 1 meter. It has been unclear whether this is due to a lack of market demand or technical limitations. Now, EOS has finally launched a metal machine with a forming size at the 1-meter level.

In October 2025, it was reported by Nanjixiong that AMCM, a large metal 3D printer manufacturer spun off from the German industrial 3D printer leader EOS, announced the launch of a "breakthrough technology in the field of large metal additive manufacturing." It is said that this new wind field airflow system, called "AirSword," enables ultra-large size laser powder bed fusion (LPBF) 3D printing without sacrificing print accuracy or part quality.

Laser Powder Bed Fusion (LPBF) and other "powder-laser" based additive manufacturing technologies face significant challenges in scaling up. AMCM points out that although LPBF technology is known for producing parts with high detail precision, its build area is difficult to exceed 1 meter by 1 meter. The core limiting factor is the poor airflow effect, which can lead to turbulence, smoke, and dust accumulation within the chamber, interfering with the laser path.

AirSword Airflow System: Breaking Through the Bottleneck of Scalable Printing

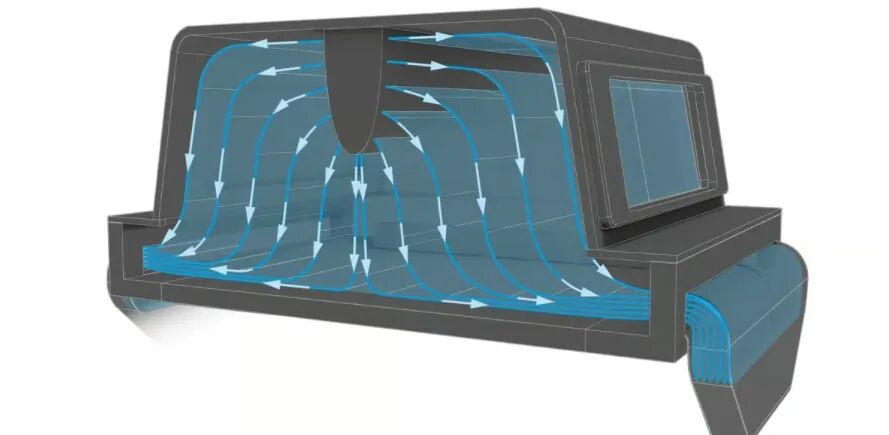

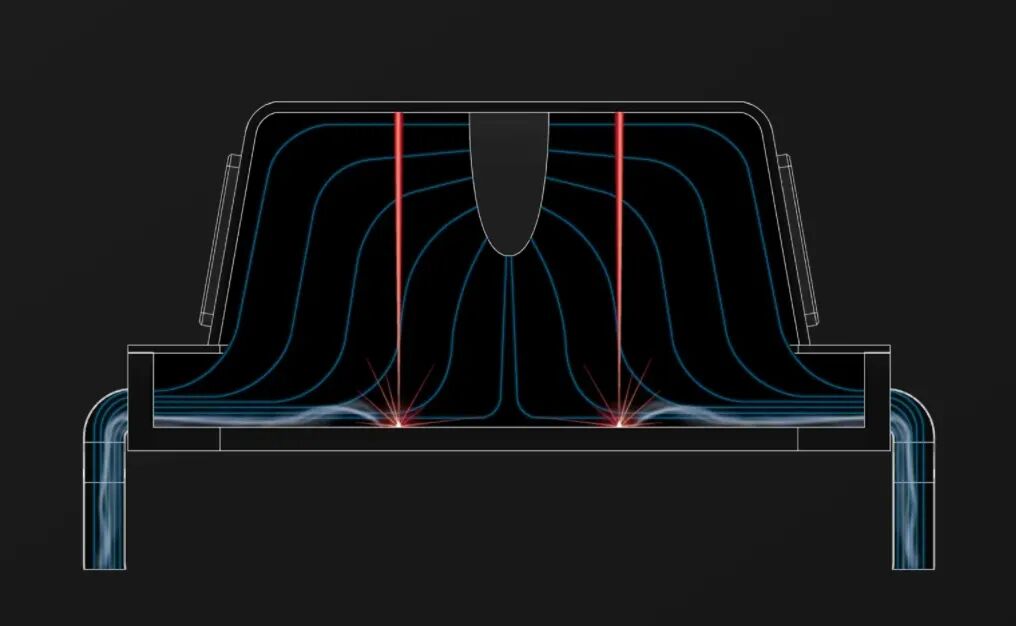

The AirSword system developed by AMCM overcomes the aforementioned limitations. In the company’s new M 8K printer and the planned M 10K and other large LPBF devices, AirSword can generate dynamic, multi-layer airflow that covers the entire printing space. The gas emitter at the center of the system divides the airflow into two opposing streams along the axis of the chamber, pushing smoke and spatter toward the exhaust openings on either side. This design prevents smoke from spreading within the chamber even during long printing processes, avoiding interference with the laser beam path.

Georg Fey, the manager of the Applications and Innovation Team at AMCM, stated: "We utilized extensive computational fluid dynamics simulations to design the AirSword system, optimizing the airflow patterns in large LPBF chambers. These simulations provided guidance for the design of the airflow nozzle outlets and the overall airflow dynamics scheme. This airflow system was manufactured using our M 4K printer, fully leveraging the design freedom of LPBF technology to create an efficient and custom-fit airflow solution."

The △AirSword system adopts a dynamic, multi-layered, and seamlessly interconnected airflow design to cover the entire printing area for debris removal (Source: AMCM).

Core Advantages and Supporting Technologies

One of the outstanding advantages of the AirSword system is its ability to continuously direct airflow to prevent the accumulation of smoke and dust, keeping the glass window and laser optical components clean. During long printing sessions, smoke and dust buildup often leads to a decline in printing accuracy.

According to AMCM, the M 8K printer is equipped with eight 1-kilowatt lasers, with a powder bed area of 0.7 square meters and a printing volume of 800×800×1200 cubic millimeters. The equipment is designed specifically for industrial-grade production efficiency, capable of handling up to 5 tons of powder while ensuring printing precision in the Z-axis direction. The upcoming M 10K printer will further expand the printing platform to a full size of 1000×1000 square millimeters.

In addition to AirSword, AMCM has also integrated advanced process control modules such as SmartFusion and EOState Exposure OT. It is reported that these modules help reduce the quality inspection phase after printing and enhance real-time monitoring capabilities.

AMCM emphasizes that by minimizing the active components in the airflow management subsystem, AirSword achieves reliable, low-maintenance operation—while retaining the core advantages of LPBF technology as the preferred solution for precision metal part manufacturing: high speed, high precision, and strong stability.

Martin Bullemer, Managing Director of AMCM, stated: "Designing systems of this size faces a number of challenges. The combination of AirSword with advanced process control technologies such as SmartFusion and EOState Exposure OT enhances quality assurance capabilities during the process and reduces the need for extensive post-printing inspections."

AMCM aims to achieve the goal of "manufacturing larger-sized metal parts" by launching the AirSword system and expanding equipment scale to the M 8K/M 10K level, without sacrificing surface quality and production efficiency.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track