Entering the Enterprise || From Manufacturing to Intelligent Manufacturing: How Did Shanghai Shaozheng Break Through?

Entering the Enterprise × Second Issue

Shanghai Shaozheng & Industry 4.0 Era

Interviewee: Shanghai Shaozheng, Gan Lulu

In this era of intense competition, companies across the upstream and downstream sectors of the modified plastics industry are being swept forward by the tides of the times, quietly working hard. As a third party, the Modified Plastics Branch aims to understand the measures or insights of upstream and downstream companies in the modified plastics industry by visiting enterprises and interviewing their leadership.

This time, the Modified Plastics Branch will take you to visit our member unit: Shanghai Shaozheng Machinery Co., Ltd.

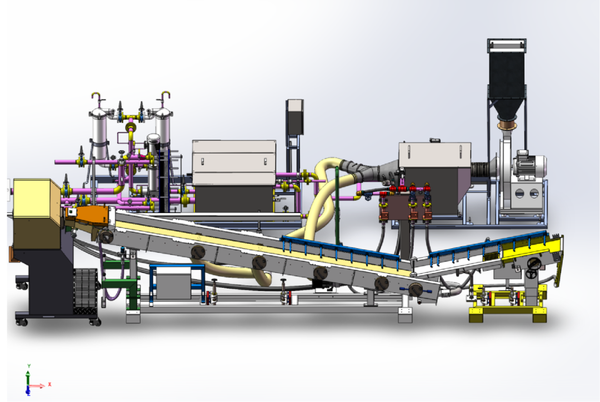

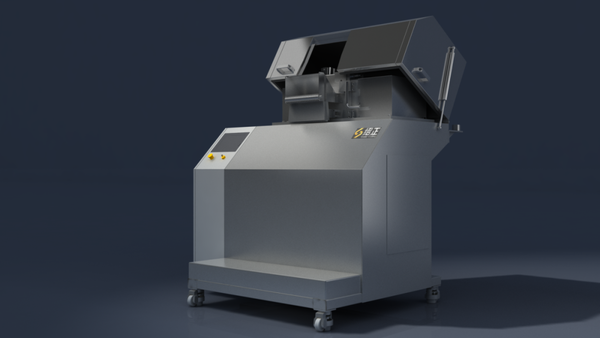

Shanghai Shaozheng Machinery Co., Ltd. (referred to as "Shaozheng Machinery") is a high-tech enterprise specializing in the research and development, manufacturing, and technical services of plastic machinery and process equipment. The company is headquartered in Shanghai. With years of experience in the modified plastics industry, it focuses on technological innovation as its core driving force, dedicated to providing efficient, intelligent, and environmentally friendly pelletizing equipment and pelletizing solutions to global customers. Its business scope covers the polymer plastic modification industry, petrochemical industry, pharmaceutical industry, cosmetics industry, and more.

Shanghai Shaozheng Machinery Co., Ltd.

Shanghai Shaozheng Machinery Co., Ltd

01

In recent years, the development of new energy vehicles and the expansion of petrochemical capacity have driven up the competitive level across the entire modified plastics industry. Under these circumstances, how did the plastic machinery and equipment manufacturing sector perform in the market in 2024?

What are your expectations for the year 2025?

In a fully competitive state, it is actually beneficial for our process equipment manufacturers. When clients face cost pressures, they tend to pay more attention to our pelletizing equipment and thoroughly study its value and cost in the production line. Based on our doubled growth data over the past two years, the market demand for high-quality equipment is robust.

So far, our first-quarter data has increased by 244.77% year-on-year. For 2025, the market's head effect will become more pronounced, and we still conservatively expect our performance to double. We can maintain excellent growth, thanks to the support and inspiration of a group of high-quality clients: not only meeting the requirements for import substitution but also having the capability to provide practical on-site solutions. Here, I am very grateful for the current market opportunities and such a group of hands-on clients!

02

Shaozheng focuses on equipment innovation in plastic modification technology. Has your company integrated industrial internet, big data, or artificial intelligence technology into the modified plastic equipment?

For example, has an intelligent mixing process control system been developed, or can it achieve real-time data monitoring and optimize production efficiency?

Yes. Everyone is exploring and establishing modified smart factories. Based on market demand, we are currently developing an intelligent strip cutting and pelletizing system. During the development, we considered using big data to help customers solve formulation processes, but through understanding the customer's site and conducting research, we found that the current market acceptance and expectations focus on adapting to on-site conditions, achieving real-time data monitoring, optimizing processes, and optimizing energy efficiency.

The determination of this important direction also comes from discussions with the end users, which is invaluable to us; otherwise, we would waste a lot of human, financial, and material resources on inappropriate directions.

03

Nowadays, everyone is talking about industrial chain collaboration. How can our equipment work with upstream and downstream companies through digital platforms to achieve technical collaboration or data sharing? Will there be customized digital service packages in the future?

This is something I have always wanted to do. Through technical collaboration and data sharing, I can obtain a large amount of quantitative production data on materials. As a manufacturer of process equipment, the data obtained from laboratories is very limited and has low reference value. If we have enough quantitative production data, we can truly develop the pelletizing process and equipment performance to the extreme. The aggregation of data inevitably involves process formulations, which is the objective reason I mentioned earlier. Currently, the equipment is not yet capable of adapting to formulated processes; it can only adapt to feedback and optimization of on-site process data.

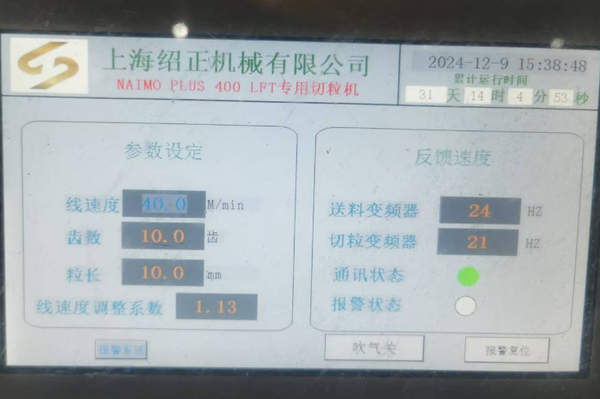

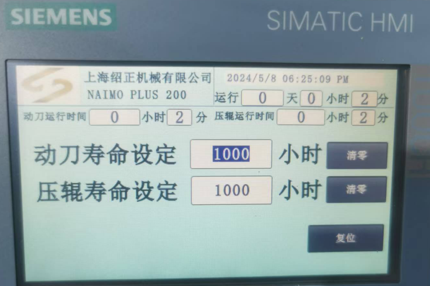

We have already implemented some customized digital service solutions. For example, our pelletizer can now display the usage time of wear parts and provide maintenance reminders. Customers can even view the production line speed and output on their mobile devices. These features help customers perform preventive maintenance on-site. Additionally, customers can evaluate equipment more objectively, avoiding subjective or human factors, and making decisions more impartially.

04

Currently, the EU requires that recycled materials account for 25% of new vehicles, and domestic carbon neutrality efforts are also stringent. How can our equipment optimize recycled materials? What breakthroughs are there in energy consumption control or the compatibility of recycled materials?

Actually, there isn't much difference between recycled plastic and modified plastic during the pelletizing stage. It's just that recycled plastic itself is of lower value, so what we need to do at the pelletizing stage is to reduce costs. There's no issue with the technology.

05

In promoting high-value recycling, does your company have any specific application cases? What assistance can you provide?

Polycarbonate (PC) recycled plastic is an environmentally friendly material made from discarded PC products such as plastic bottles and electrical appliance casings through processes like crushing, cleaning, melting, pelletizing, and drying. This recycled plastic retains physical and chemical properties similar to virgin polycarbonate but is more cost-effective. For virgin PC, we have collaborations with domestic companies like Wanhua, Luxi, Cangzhou Dahua, and Teijin, and our technology is well-established. Our focus in the pelletizing stage is still on cost reduction. Using recycled polycarbonate can reduce reliance on virgin plastic and help lower environmental pollution. In this regard, we will actively contribute our part to environmental protection.

06

Many automakers and modification companies are now expanding into Southeast Asia. Does this have a significant impact on our business? Does our company currently have any plans in this regard?

Currently, there is indeed a trend of relocation, but the investment in the modification industry abroad is still in the trial phase, with a cautious approach, resulting in relatively low-quality equipment investments. Given our company's product positioning, we are currently in a wait-and-see mode. Of course, the market is being explored through various channels, but there are no immediate plans to establish a factory.

07

According to what we know, your company will participate in the rubber and plastics exhibition this April. Could you give us a sneak peek of what new technologies will be showcased? What specific pain points and needs of customers will these mainly address?

Our technological innovation cycle in the process equipment industry is not that fast. The products we showcased this time are actually based on technology from two years ago, and they have received excellent market feedback. Our NAIMO PLUS series is called "Zero Glue Explosion, No Pollution, Precise Delivery, High Output," addressing the market demand for completely avoiding glue roller explosions that contaminate materials and increasing production output. Additionally, our latest intelligent strip-cutting pelletizing system will be unveiled at our factory. We look forward to meeting both new and old friends. Thank you!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics