ENGEL Tie-Bar-Less Technology 35th Anniversary: Forging the Path of Innovation and Evolution in the Injection Molding Industry

In 1989, when ENGEL first introduced the tie-bar-less injection molding machine at the K fair in Düsseldorf, the industry’s reactions were mixed: there were technical praises as well as public doubts. At that time, few could foresee that this “revolutionary” design would become one of the successful technologies in the field of injection molding machinery. Thirty-five years later, ENGEL has delivered over85,000 unitsThe model without tie bars, and continuously driving innovation with a focus on customer needs. At the K 2025 exhibition this year, ENGEL willGlobal Debut of the New Generation Fully Electric Tie-bar-less Injection Molding Machine。

The inspiration for the development of the tie-bar-less technology stemmed from practical needs: a customer complained to ENGEL that the traditional four tie-bar structure severely interferes with mold installation, and that changing molds would be much more convenient without the obstruction of tie-bars. Based on this, the ENGEL development team began researching whether it was possible to completely eliminate the tie-bars in the clamping unit of injection molding machines. This seemingly simple idea led to a significant breakthrough in mechanical design—previously, regardless of machine size or application scenario, "injection molding machines must be equipped with four tie-bars" was considered an unshakeable engineering principle. The birth of the tie-bar-less clamping unit marks a complete revolution in design philosophy.

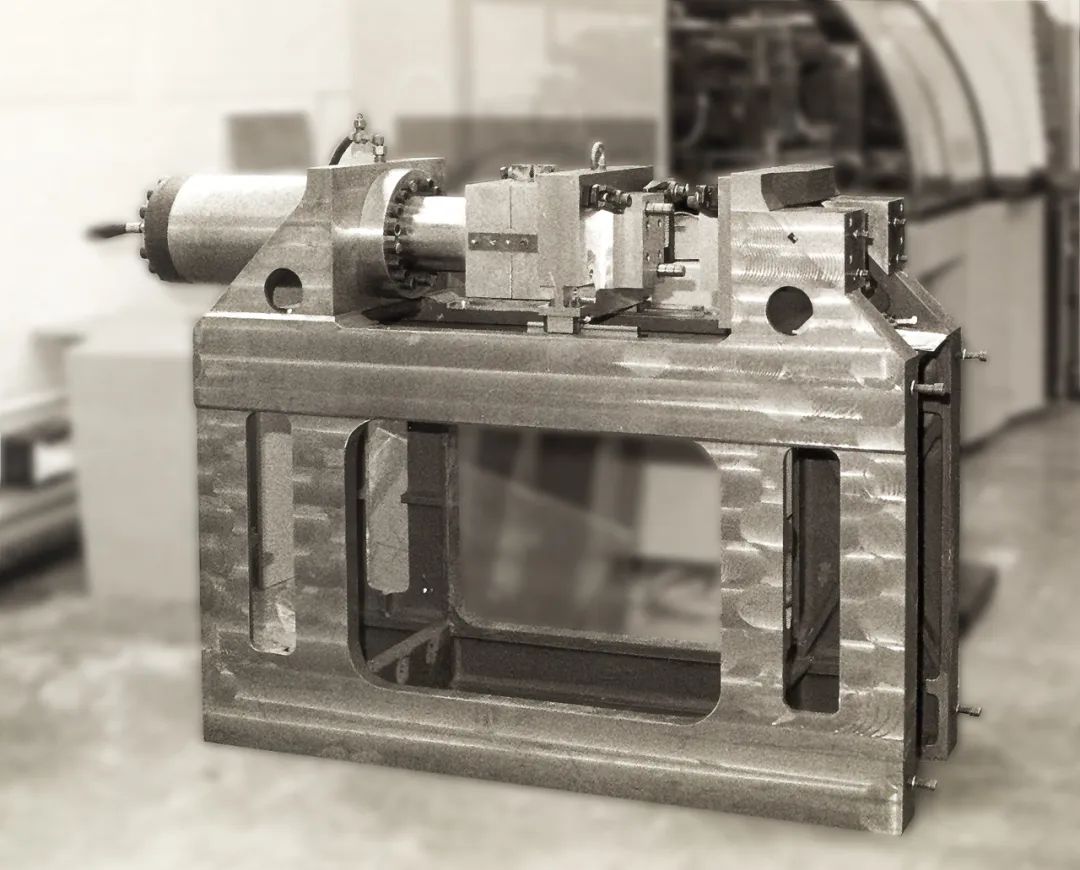

The first rodless frame in the laboratory. This revolutionary concept has achieved global success by delivering significant customer value.

Technical Breakthrough

ENGEL solved the problem of asymmetric force on C-frame structures through an innovative joint principle: replacing traditional tie rod guidance with a robust frame and utilizing a freely moving bending rod joint between the moving platen and the clamping piston (later patented as the Force Divider system). This Flex-Link flexible connecting element ensures absolute parallelism of the mold parting surfaces, while simultaneously achieving uniform clamping force distribution across all cavities of the platen and the entire mold surface. The new model, born from this innovation, is not only renowned for its technical advantages but also opens up new dimensions in mold design. The first complete production line was launched in 1990, and in 2000, the series was officially named "victory."

The evolution of fourth-generation technology and the accumulation of experience

From manually lubricated sliding bearings in prototype machines to today's Flex-Link systems with decentralized force application, ENGEL continues to improve the joint system of tie-bar-less machines while expanding the product line and introducing new drive technologies.

The current ENGEL tie-barless machine models cover three major series.

Hydraulic Victory Series

Suitable for versatile industrial injection molding.

Hybrid E-Victory Series

The electric injection unit meets the requirements for high-precision parts.

All-electric Victory Electric series

Designed for demanding applications such as large-volume precision components.

All three have the inherent advantages of a tie-bar-less clamping unit: larger mold installation space, quick mold change, user-friendly operation interface, and flexible automation integration. The open template design also enables the application of large and complex molds on machines with lower clamping force, significantly reducing investment costs.

The ENGEL victory series' tie-bar-less technology provides ample space for large molds and automation systems, and the large platens often eliminate the need to purchase higher tonnage models.

Adhering to principles leads to success.

ENGEL's unique position in the tie-bar-less field is not only due to its first-mover advantage in technology but also benefits from continuous iteration and refinement of its patent layout. Its design value is particularly evident in multi-cavity mold scenarios with small projected areas — compared to traditional models, it can reduce energy consumption by up to 30%, while also decreasing equipment size and procurement costs.

Energy Efficiency Innovation Milestone

The introduction of ecodrive servo-hydraulic drive technology reduces the energy consumption of hydraulic machines to the level of electric machines, making it an ideal solution for high energy efficiency requirements when combined with a tie-bar-less design. Currently, all ENGEL hydraulic and hybrid models are equipped with the ecodrive system as standard.

Facing the Future: Modular, Integrated, Sustainable

The key to the enduring vitality of the tie-bar-less technology over 35 years lies in its outstanding adaptability. Whether for cleanroom applications, multi-component processes, or highly automated production units, ENGEL models can meet demands through modular configuration.

K 2025 Outlook: A New Era of Electric Technology

The current K Exhibition will debut a new generation of electric tie-bar-less models, focusing on the added value brought by design upgrades, continuing the 35-year tradition of "customer questions driving innovation."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track