Efficiently attending k fair: A Review of New Products from 12 International Blending Machinery Manufacturers

2025K ExhibitionThe event is about to come to an end, and the highlight technologies from major console manufacturers have all been showcased. By closely following the exhibition information, we have compiled this for you.Sort by the first letter of the company name.The inventory of blending host equipment takes you on a cloud review of the core equipment trends of this exhibition.

BUSS (Switzerland)

Hall 16 A59

1

COMPEO Application Panorama: From Laboratory to Production

Brand new CPS-F3 model grandly launched! The new digital platform SenseHub is released, with performance data, spare parts, upgrades, and after-sales service all "online in real-time."

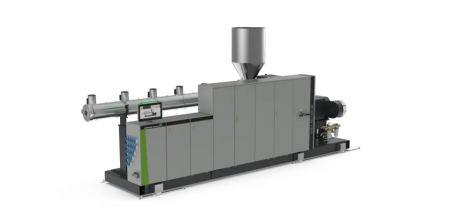

Battenfeld-Cincinnati (Germany)

16 Hall B19

1

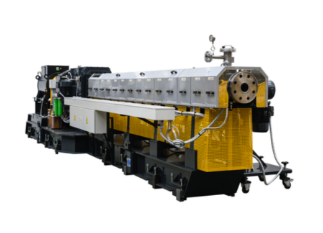

Single-screw extruder solEX NG 105

The first independent closed cooling circuit was created.

Achieve a high output of 2100 kg/h under melting conditions that are 10°C lower than the usual processing temperature.

Koeberlein (Germany)

14 Hall B19

1

Twin-screw extruder ZSK 58 mc¹⁸

The screw diameter is 58mm, with a specific torque of 18 Nm/cm³, featuring low energy consumption and high automation, achieving a production capacity of 2,500 kg/h.

Equipped with Coperion's screw elements specifically developed for processing fillers (reducing wear in the melting section).

2

Twin-screw extruder for masterbatch production STS 35 Mc¹¹

The specific torque is 11.3 Nm/cm³, and the output can reach 300 kg/h.

The tightly intermeshing twin screws and the smooth machine surface are easy to clean and maintain.

CPM (USA)

Hall 14, B31

1

GXT Series Twin-Screw Extruder

Specific torque of 13 Nm/cm³, length-to-diameter ratio options available from 40:1 to 48:1, maximum speed of 1200 RPM.

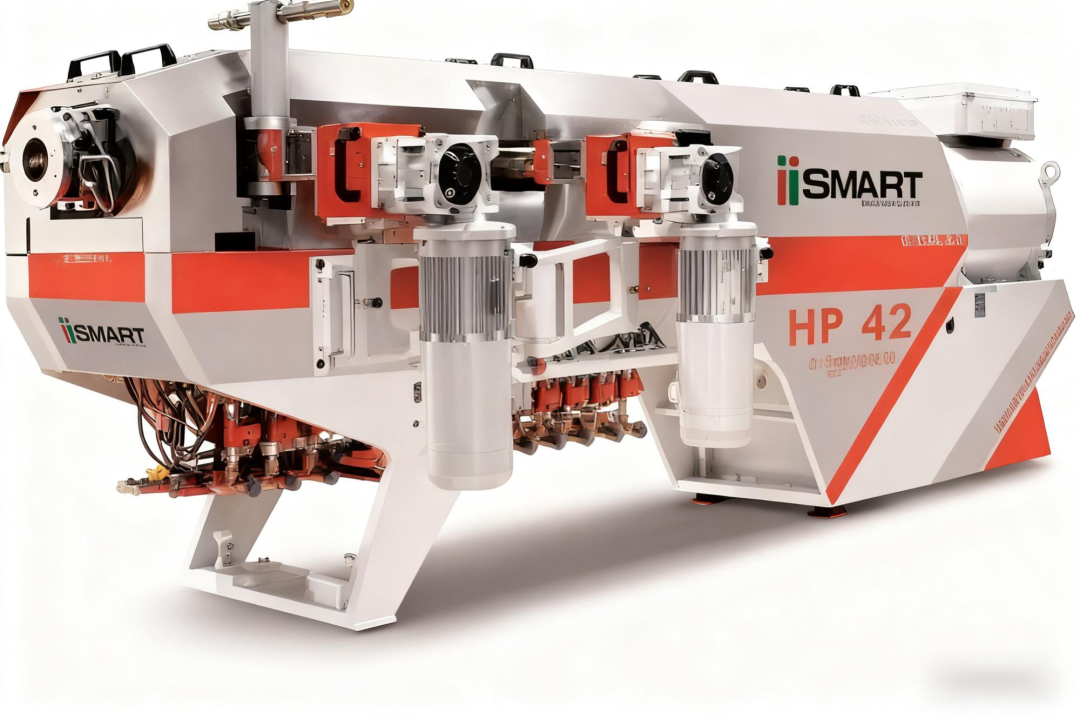

ICMA San Giorgio SpA (Italy)

Hall 16 B05

1

Twin-screw extruder high torque HP series

Modular gearbox design, adaptable to the composite processing needs from special engineering polymers to bio-based materials.

JSW (Japan)

Hall 13 B77

1

TEX44 αRⅡ

Specific torque 15.3Nm/cm³, screw diameter 25-90mm, using barrel heating for precise temperature control.

KraussMaffei (Germany)

Hall 14 B19

Short Fiber Direct Compounding Process====

The first direct compounding of chopped glass fibers and polypropylene is achieved with a patented special screw geometry design ensuring uniform mixing and gentle processing. It can be directly modified to be compatible with KraussMaffei injection molding machines.

2

Twin-screw extruder ZE BluePower

High energy efficiency, cost-effectiveness, and shorter delivery times, and can be digitally networked through the ppC control system.

LestradeGermany)

Hall 16, F22

1

ZSE 27 CC China Manufacturing Series Extruder

Germany imports key components and technology and modifies and assembles them locally in China.

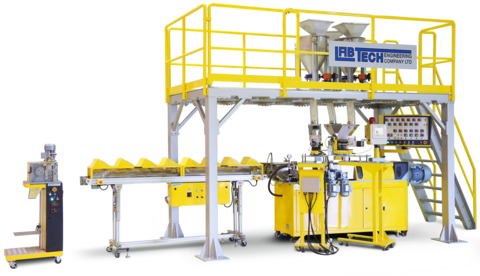

Labtech-Engineering (Thailand)

Hall 7/C37-01

1

Composite production line solution, including extruder units,

Downstream auxiliary equipment and high-speed mixer integrated into one.

-

Standard Series – Both single-screw and twin-screw extruders are available in micro, laboratory, and pilot research models, suitable for processing various materials and compatible with multiple downstream processes.

-

Recycling Series – Single-screw extruder equipped with a special screw and feeding device, suitable for high-output waste processing, available in two specifications: 16mm and 25mm diameter.

Maris (Italy)

Hall 16 B59

Co-rotating twin-screw extruder

Optimized specifically for plastic and rubber compounding, supports continuous feeding, and performs excellently in recycling and other fields.

Steer (India)

Hall 12/C54-02

1

TITAN Series Extruder

High torque, compact design, optimized barrel cooling, and quiet operation design to reduce noise.

2

Omega Co-rotating Twin-screw Extruder

Optimized specifically for applications requiring high free volume, shear sensitivity, and low bulk density, and can be equipped with patented combination block elements.

Union (Italy)

Hall 16 B60

At this K exhibition, there are many highlights in the areas of intelligentization and energy efficiency for compounding machines. Due to the numerous exhibition halls, a comprehensive review may be incomplete.Welcome fellow colleagues to contribute the highlight devices you have observed~

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track