DuPont Acquires!

[DT New Materials]On September 29, DuPont announced that it had signed an agreement to acquire Sinochem (Ningbo) Ruwo Membrane Technology Co., Ltd. This acquisition aims to expand its reverse osmosis (RO) manufacturing business footprint to China and the Asia-Pacific region to better serve these areas.The increasing industrial water purification and reuseIn response to the increasing demand for FilmTec™ products, to support the company's strategy of localized production that is closer to end customers, enhance logistics reliability and supply chain risk management, and reduce carbon footprint. The transaction is expected to be completed in the fourth quarter of 2025.

According to reports, this production facility will be DuPont's third RO production base, building on the most advanced production facilities in Edina, Minnesota, USA, and Jubail, Kingdom of Saudi Arabia. DuPont has already obtained the qualification for this plant.

Reverse osmosis (RO) technology is used for desalinating brackish and seawater, with various applications including industrial and municipal water treatment, power generation, food and beverage processing, and water reuse.New reverse osmosis membrane materials with antioxidant properties, acid-base resistance, and high permeability, as well as reverse osmosis membrane components with low energy consumption, anti-fouling, high temperature resistance, high pressure resistance, and special separation performance, are the main development directions.

DuPont is a world leader in this field, addressing various challenges faced by water treatment municipalities, desalination plants, and industrial water users (including the microelectronics industry) through a comprehensive range of membranes, resins, and complete system combinations. Other important players in this field include Nitto Denko, Toray, Dow Chemical, GE, and LG Chem. Domestically, there are Waton Technology, Hangzhou Water Treatment, VSEP, OriginWater, Jiuwu Hi-Tech, and Senda Membrane, among others.

The data shows that.Sinochem (Ningbo) Runwo MembraneEstablished on January 8, 2019, with a registered capital of 675 million RMB, it is located in Xiangshan County, Ningbo City, Zhejiang Province. It is a state-owned enterprise controlled by Sinochem International Corporation (holding 77.7778% of the shares), with the remaining 22.2222% held by Xiangshan Economic Development Zone Investment Co., Ltd.

The company focuses on the research and development, manufacturing, and sales of separation membrane materials such as composite reverse osmosis membranes and nanofiltration membranes, and is committed to promoting water treatment technology and engineering services. In March 2024, the project with an annual production capacity of 220,000 reverse osmosis membranes passed the construction engineering file acceptance.

DuPont did not disclose the specific price of this acquisition in the announcement. However, on August 18, 2025, 100% equity of Sinochem (Ningbo) Runwo Membrane was officially listed on the Beijing Equity Exchange, with a transfer base price of 512 million yuan.From the table, it can be seen that the company's performance is in a loss state. In the first five months of 2025, the net profit was -20.9093 million yuan, revenue was 0, and net assets were 378.453 million yuan.

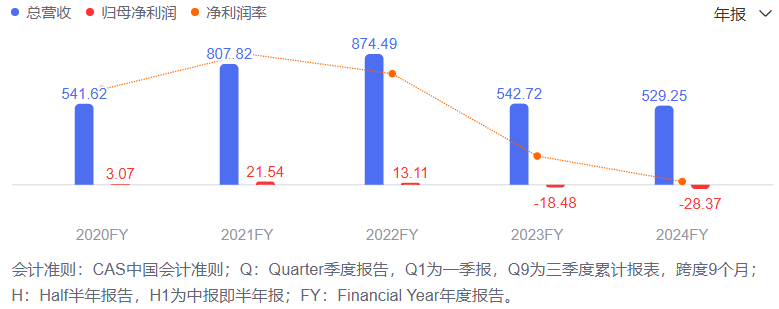

As the parent company, Sinochem International's performance has also been unsatisfactory in recent years.In 2023, the operating revenue was 54.272 billion yuan, a year-on-year decline of 37.94%; the net profit attributable to the parent company was a loss of 1.848 billion yuan, a year-on-year decrease of 240.99%. In 2024, the net profit attributable to the parent company was -2.837 billion yuan, a year-on-year decrease of 989 million yuan. In the first half of 2025, the revenue was approximately 24.4 billion yuan, a year-on-year decline of 5.83%; the net profit attributable to the parent company was a loss of 886 million yuan, turning from profit to loss, a year-on-year decrease of 7291.9%.

On August 20, apart from Sinochem (Ningbo), the investor of Huaian Junsheng New Energy Technology Co., Ltd. changed from Sinochem International to Xingdong (Hebei) Lithium Battery Technology Co., Ltd. The company's main business is the research and development, production, and sales of lithium-ion batteries and battery packs.

It is reported that.Junsheng New Energy specializes in pouch power batteries, covering technologies such as LFP and NCM, with an annual production capacity of 2GWh. The company has also ventured into the research and development of sodium-ion batteries and solid-state batteries.

In September 2018, Sinochem International signed an investment cooperation intention agreement with Junsheng New Energy and Borgward Automotive, announcing plans to invest 10 billion yuan to build a power battery production base in Huai'an, Jiangsu, with plans to construct 10 lines for the research, development, and production of battery cells and battery packs.

In 2021, however, Junsheng New Energy's partner, Borgward Automobile, entered bankruptcy reorganization proceedings. In June 2025, Tianjin Borgward Automobile Co., Ltd. was ordered by the court to enter bankruptcy liquidation.

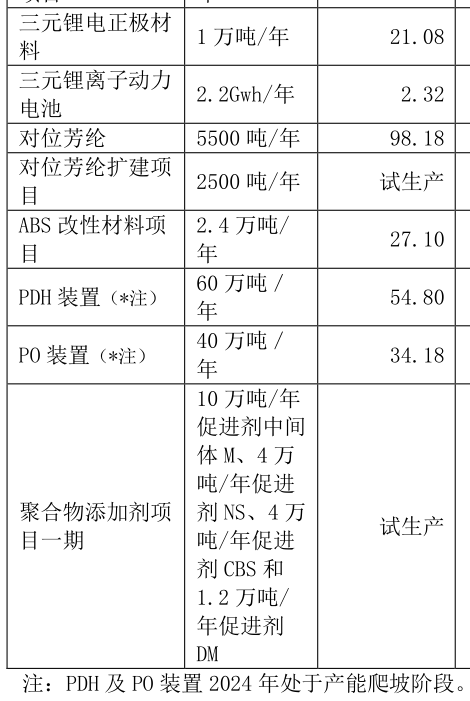

In addition, in the field of lithium batteries, Sinochem International established Ningxia Sinochem Lithium Battery Materials Co., Ltd. in 2018, which has an annual production capacity of 10,000 tons of ternary cathode materials.In 2024, the capacity utilization rate was only 21%, total liabilities reached 301 million yuan, and the loss for the year was approximately 525 million yuan.In addition, in 2019, Sinochem International established Sinochem Yangzhou Lithium Battery Technology Co., Ltd., and recently the company's legal representative was changed to...The legal representative of Sinochem Green Energy Technology (Shanghai) Co., Ltd. is Lu Xiaoliang.

Despite setbacks in the new energy sector, Sinochem International's foundation in chemicals remains solid. It is building a "2+2" core chemical new materials industry chain that includes epoxy resin, polymer additives, engineering plastics, and specialty fibers, involving products such as aramid, nylon, and epoxy resin.Bisphenol A...and various other products.

In addition, the company's special nylon (MXD6) polymerization and application technology development project has achieved a breakthrough in the hundred-ton level MXD6 polymerization process, with stable product quality and main indicators reaching the level of imported benchmark products. The synthesis and application technology development of polydivinylcyclopentene (PDCPD) has completed the preliminary design for engineering at the thousand-ton level. The ton-level facility for ethylene maleic anhydride (EMA) is operating stably, and the products have been validated by downstream application field customers. The aviation tire aramid cord project has met all design requirements, and some products have passed third-party testing and certification. The industrialization preparation work for methyl isobutyl ketone (MIAK) engineering tests is progressing smoothly.

What is particularly noteworthy is,Sinochem International is issuing shares to acquire China BlueStar.The wholly-owned subsidiary of the (Group) Co., Ltd., Nantong Xingchen Synthetic Material Co., Ltd., holds 100% equity, which possesses multiple large-scale chemical production facilities for PBT, PPE, Bisphenol A, and epoxy resin, with a total capacity exceeding 400,000 tons. Its PPE products rank first domestically and second globally, while its Bisphenol A, PBT, and basic epoxy resin products rank among the top three in China. Additionally, it is recognized as a national manufacturing champion in polyphenylene ether, with a capacity of 50,000 tons per year. Furthermore, the company has applied for patents on new materials such as polyphenylene sulfide, low molecular weight poly(arylene ether), polyester composites, and bio-based degradable polyester.

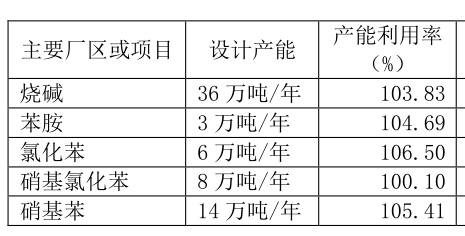

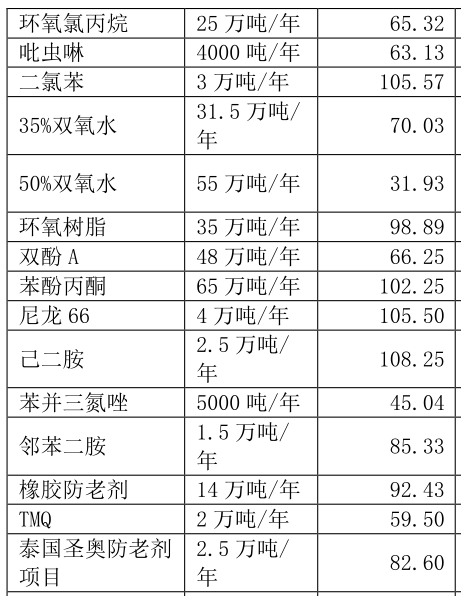

As of the end of 2024, the production capacity of Sinochem International products is as follows:

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track