Dow reports $7.8 billion loss, wacker chemie announces layoffs, dupont antitrust investigation paused, agc transfers pc business

This week's major news: Borealis suspends its Austrian recycling plant project; Dow Chemical's Q2 losses widen to 7.8 billion yuan; the anti-monopoly investigation of DuPont China by the State Administration for Market Regulation has been suspended.

In terms of production capacity, BASF's Zhanjiang acrylic acid plant has been mechanically completed; Wanma Co., Ltd. plans to invest 1.2 billion yuan in a high polymer material project; Zhongtian Technology's 300-ton PI film project has been successfully trial-produced; Yike Chemical's 225,000-ton ABS plant has been put into operation.

In terms of material innovation, Arkema has launched the Zenimid polyimide brand; SABIC has released flame-retardant PBT nano injection molding materials; BYK has introduced a polyamide UV stabilizer; INEOS Styrolution has launched bio-based PS food packaging materials. For more industry insights, please read this issue of [Weekly New Material Plastics Delivery].

Company News

Borealis suspends Austria polyolefin recycling plant project.

Borealis has temporarily shelved its plans to build a mechanical recycling plant for polyolefin waste in Schwechat, Austria. A spokesperson for the group stated that a detailed evaluation of the project revealed that, under the current market conditions, the plant could not "meet the expected performance targets." As a result, the project has been put on hold.

The largest in the country! Suppliers of Wanhua Chemical and Meirui New Materials are launching an IPO.

Recently, the IPO of Hunan Jurin New Materials Co., Ltd. (Jurin New Materials) on the Beijing Stock Exchange has been accepted.

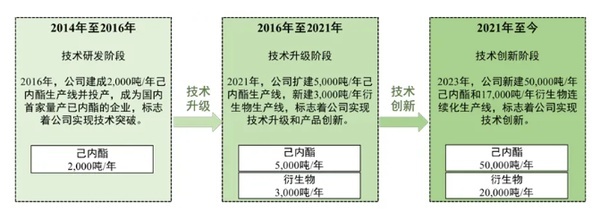

Juren New Material was established in 2014, with its headquarters located in the Yueyang Green Chemical Industry Park, Hunan. The company focuses on the research and production of caprolactone (ε-CL) and its derivatives. The breakthrough in the company's core technology began in 2016—amidst foreign technology blockades, it independently built the first domestic kiloton-level caprolactone industrial unit, breaking the monopoly of Europe and the United States. Since then, the company has continuously iterated its technology, achieving mass production of polycaprolactone (PCL) biodegradable materials in 2021. In 2023, it launched a production line with the largest single-unit capacity in the world, producing 50,000 tons/year of green biodegradable materials, with product performance benchmarked against international giants BASF and Daicel.

Dow Chemical, a loss of 7.8 billion!

On July 24th, Dow Chemical released its second-quarter earnings data, showing a decline in performance across all departments and an increase in losses.

From an overall data perspective:

Net sales: $10.1 billion, a year-on-year decrease of 7%, with declines across all operating segments. A quarter-on-quarter decrease of 3% (1Q25 was $10.4 billion).

(2) Sales: Down 1% year-on-year and 2% month-on-month, with growth in the United States and Canada offset by declines in Europe, the Middle East, Africa, and India.

(3) Price: Decreased by 7% year-on-year and 3% month-on-month, mainly due to the pressure on global chemical product prices.

(4) GAAP Net Income: A loss of $801 million. In the first quarter of 2025, this figure was -$290 million, meaning the company’s total loss for the first half of the year reached $1.091 billion, approximately 7.8 billion RMB!

(5) Operating EBIT: A loss of $21 million, a year-on-year decrease of $840 million, primarily impacted by price declines and reduced equity earnings. It decreased by $251 million quarter-on-quarter, despite favorable currency exchange rates and company cost-cutting initiatives, which were offset by declines in the packaging and specialty plastics divisions.

(6) Cash flow from operating activities: negative $470 million, a year-on-year decrease of $1.3 billion and a quarter-on-quarter decrease of $574 million, primarily due to compressed profit margins.

However, Dow recently won a lawsuit against Nova Chemicals and will receive an additional compensation of 1.62 billion Canadian dollars (approximately 8.5274 billion RMB), which is expected to be paid in the fourth quarter of 2025. This will significantly improve the company's overall financial data for this year.

Breaking News! DuPont's Antitrust Investigation in China Suspended!

On July 22, according to the website of the State Administration for Market Regulation, the State Administration for Market Regulation has suspended the antitrust investigation procedures against DuPont China Group Co., Ltd.

On April 4th of this year, due to the suspected violation of the "Anti-Monopoly Law of the People's Republic of China" by DuPont China Holding Co., Ltd., the State Administration for Market Regulation lawfully initiated an investigation.

According to reports, DuPont established a representative office in Beijing in 1984 and registered DuPont China Group Ltd. in Shenzhen in 1988, becoming one of the first Fortune 500 companies to invest in China and the first wholly foreign-owned investment company approved by the Chinese government.

BDO Enterprise Tongde Chemical is embroiled in a contract dispute, with net profit forecast to plummet 80% in the first half of the year!

On the evening of July 21, Tongde Chemical (SZ002360, stock price 5.84 yuan, market value 2.346 billion yuan) announced that due to a contract dispute, some bank accounts of the company and its wholly-owned subsidiary Tongde Kechuang Materials Co., Ltd. (hereinafter referred to as "Tongde Kechuang") were frozen by the People's Court of Laoshan District, Qingdao City, with a frozen amount of 87 million yuan. As of the date of this announcement, the frozen balance of the four accounts is 10.9193 million yuan.

Tongde Chemical stated in the announcement that the company's production and business activities are proceeding normally and have not been significantly adversely affected by the freezing of the bank account. Recently, Tongde Chemical has been involved in several financial leasing contract disputes, but all have been resolved through pre-litigation mediation.

Carbios enters the market for recycled PET yarn for tires.

Recently, Carbios announced a multi-year commercial agreement with Indorama Ventures, which involves the supply of monomers obtained by enzymatic depolymerization of PET waste from its Longlaville plant. These monomers will then be converted by Indorama into recycled PET filaments, which will ultimately be used by Michelin for tire manufacturing.

With its enzymatic PET recycling technology, Carbios will produce monomers from complex PET waste at its future industrial site in Longlaville. Indorama Group will be responsible for the repolymerization and production of industrial yarns, while Michelin will use these creations.New MaterialsUsed for tire reinforcement components.

BASF Zhanjiang's first batch of units has been mechanically completed!

On July 21st, it was reported that the first batch of equipment in the acrylic acid and ester zone at BASF's Zhanjiang Verbund site has been mechanically completed.

BASF's Zhanjiang Verbund site has reached an important milestone with the mechanical completion of the first batch of installations in its acrylic acid and esters complex, including the Glacial Acrylic Acid (GAA) and Butyl Acrylate (BA) units. This progress marks a critical step towards the site's goal of officially starting production in 2025 and strengthens BASF's leading position in the global acrylic acid market.

Acrylic acid is an important precursor for the production of superabsorbent polymers. Butyl acrylate, being one of the esters of acrylic acid, is widely used in the production of adhesives, architectural coatings, and industrial coatings. The butyl acrylate plant at BASF's Zhanjiang Verbund site is designed with an annual production capacity of approximately 400,000 tons and is scheduled to start operations in 2025.

Wanha Co., Ltd. subsidiary plans to invest 1.245 billion yuan to expand production.

On July 23, Zhejiang Wanma Co., Ltd. announced that its subsidiary, Zhejiang Wanma Polymer Materials Group Co., Ltd. (hereinafter referred to as "Wanma Polymer"), plans to construct a "35,000-ton-per-year eco-friendly polymer materials industrialization project" in the Dongjiakou Economic Zone, Qingdao City, Shandong Province. The total investment is expected to be approximately 1.245 billion yuan (subject to the actual investment situation).

According to the announcement, the project will be advanced by establishing a new company, planning to acquire industrial land, construct standardized factories and supporting facilities, and add multiple production lines. It will focus on the production of silane cable materials, low-smoke halogen-free cable materials, PVC (polyvinyl chloride) cable materials, and shielding materials for cables. The project funding will be provided by Wanma Polymer through its own funds or self-raised funds in cash, along with supporting medium to long-term project loans from banks, and will be gradually invested according to the investment progress. The project will be constructed in three phases, with a cycle from 2025 to 2030.

AGC transfers its polycarbonate business to Sumitomo Bakelite.

On July 22, 2025, AGC Inc. of Japan announced that it has reached an agreement with Sumitomo Bakelite Co., Ltd. to transfer its polycarbonate business.

According to its medium-term management plan "AGC plus-2026," AGC Inc. aims to build a business portfolio that can effectively respond to market fluctuations, has high asset efficiency, strong growth potential, and high carbon efficiency.

AGC Inc.'s polycarbonate business has a history of over 30 years, offering a rich product line in a wide range of fields including construction materials, industry, and electronics to meet customer needs. Among them, TWINCARBO™ and polycarbonate sheets for optical applications are renowned in the market.

61 companies have committed to investing 631 billion euros in Germany over the next three years.

Germany is facing the risk of a third consecutive year of economic stagnation. Against this backdrop, a corporate joint initiative called "Made for Germany" has attracted widespread attention. A total of 61 German and international companies and investors, including Siemens, Deutsche Bank, BASF, BMW, Henkel, Infineon, ZF, and Rheinmetall, have pledged to invest approximately 631 billion euros in Germany over the next three years. This investment will be used for the construction of new factories, research and development projects, and the modernization of infrastructure.

Breaking: Wacker Chemie is laying off employees!

Recently, Wacker Chemie AG announced a strategic layoff plan, which will affect approximately 90 of the nearly 650 employees at its production site in Charleston, Tennessee, USA. This decision is part of the company's extensive restructuring plan aimed at responding to the changing market environment and ensuring the long-term sustainability of its business.

Capacity dynamics

The annual production of 300 tons of high-performance PI film project has been successfully put into production.

On July 19th, it was reported by the media that Zhongtian Electronic Materials Co., Ltd., a subsidiary of Zhongtian Technology, has successfully commenced trial production of its "Annual Output of 300 Tons of High-Performance PI Film Project," and the first batch of products will be supplied to the market in the third quarter of this year.

According to reports, the company announced on February 27 that it plans to raise 357 million to invest in high-performance PI (polyimide) films.

The company stated that the project will be constructed in two phases, with the first phase having a construction period of 26 months and the second phase having a construction period of 18 months. Once fully completed, it will have an annual production capacity of 600 tons of high-performance polyimide (PI) film series products.

The annual production of 100,000 tons of modified engineering plastic granules project has officially commenced.

On July 21, 2025, the project to produce 100,000 tons of modified materials annually, invested by Jiangxi Jinxin New Materials Co., Ltd., was launched.Engineering plasticsThe granule production construction project has officially broken ground. The total investment in this construction project is approximately 120 million yuan, with a planned land area of 52.66 acres. The core construction content includes the establishment of 16 new high-strength modified engineering plastic granule production lines, aiming to create a first-class intelligent production base in China.

The 3,000-ton flame-retardant masterbatch project has been successfully trial-produced!

On July 23, it was reported that Guangxi Huayuan Metal Chemical Co., Ltd., a managed enterprise under Huaxi Nonferrous (600301), achieved a significant breakthrough. Its key project, the annual production line of 3,000 tons of flame-retardant masterbatch, successfully completed its trial production in one go, producing the first batch of qualified products! The products released this time include PE80 and PVC80, which have been rigorously tested by professional institutions and meet all performance standards. This fully demonstrates that the production line is ready for official production.

In April this year, the project was officially launched, aiming to fill the company's gap in the high-end antimony deep processing field. On June 22, the core equipment was successfully delivered and quickly commenced installation and commissioning. After less than three months of construction, trial production was successfully achieved on July 15, producing qualified products.

Huitong Bio: Successful trial production of 35,000 tons of high-weather-resistant fiber-grade polylactic acid chips.

Yangzhou Huitong Biomaterials Co., Ltd. (hereinafter referred to as Huitong Biomaterials) has commenced trial production of its 35,000-ton annual capacity polylactic acid project (Phase I), with the first batch of qualified products successfully rolling off the line. This project utilizes the lactide production process and key equipment independently developed by Yangzhou Huitong Technology Co., Ltd., and employs Sulzer's lactide purification and polymerization key equipment and technology. The products produced have breakthrough solutions to the pain points of polylactic acid products, resulting in differentiated advantage products—high weather-resistant fiber-grade polylactic acid chips for textiles.

22.5 million tons/year! Yike Chemical's mass polymerization ABS has been successfully put into production in one go!

On July 18, 2025, Yike Chemical Co., Ltd. (hereinafter referred to as "Yike Chemical") successfully initiated the first phase of its ABS resin project with a capacity of 225,000 tons per year, achieving a one-time successful start-up and producing high-quality qualified products. The commissioning process was smooth and efficient, with the facility operating stably and reliably. Particularly exciting is that the performance indicators of the first batch of products, including physical properties, base color, impurity content, and volatile content, all meet the most stringent testing standards, fully capable of meeting the needs of high-end application fields. This not only marks the successful operation of the facility but also confirms Yike Chemical's leading position in ABS production technology and quality control.

Innovative Materials

Evant Launches First Product in ColorMatrix Amosorb Oxyloop Series

Avient Corporation announced the launch of the first product in its new ColorMatrix Amosorb Oxyloop oxygen scavenger series — ColorMatrix Amosorb Oxyloop-1. This oxygen scavenger additive is designed to enhance the recyclability of polyethylene terephthalate (PET) packaging, while also helping to extend product shelf life, achieve sustainability goals, and accelerate the transition to a circular economy.

Arkema launches new brand name Zenimid™ for its high-performance polyimide product line.

Arkema and its affiliate, PI Advanced Materials, have announced the launch of a new brand name for their flagship high-performance polyimide products: Zenimid™. Zenimid™ polyimide is designed for use in the most demanding environments and offers exceptional dimensional stability, flexibility, heat resistance, chemical resistance, and electrical insulation. The material is available in films, varnishes, and profiles, with applications including flexible printed circuit boards (FPCBs) and graphite sheets in smart devices, battery management systems (BMS), and 5G infrastructure.

SABIC Launches First Flame-Retardant PBT Nano Injection Molding Material with Good Adhesion Strength and Mechanical Properties

On July 16, 2025, SABIC announced the launch of a new product in its LNP™ THERMOTUF™ specialty compound series. The new LNP™ THERMOTUF™ WF0087N compound is the industry's first nano-molding technology (NMT) material based on polybutylene terephthalate (PBT), offering exceptional flame retardancy and excellent mechanical properties. It meets the growing demand in the consumer electronics industry for lightweight and durable metal-plastic composite components, such as smartphone frames. Additionally, the flame retardant properties of this material can help customers comply with the latest edition of the IEC 62368-1 safety standard for consumer electronic equipment. The LNP™ THERMOTUF™ WF0087N compound has been honored with the 2025 Edison Award.

BYK Chemie introduces an innovative UV stabilizer that provides long-lasting protection for polyamide performance in harsh lighting environments.

At this year's Düsseldorf International Plastics and Rubber Exhibition (K 2025), BYK-Chemie will introduce an innovative solution designed to provide long-lasting UV stability for polyamide and polyolefin composites. This new additive is developed to address the performance and surface quality of plastics in prolonged exposure to light. Polyamide-based materials can experience performance degradation and surface deterioration under continuous light exposure, which not only reduces physical properties but often leads to color changes and loss of gloss.

Polyamide is indispensable in many fields due to its excellent mechanical strength, high-temperature resistance, and versatility—from the automotive industry and building materials to consumer goods and recreational products, as well as fibers and textiles. However, exposure to ultraviolet light can cause the material to discolor, lose its luster, and degrade.

Material Application

Opening a New Green "Food" Era! Bio-based Polystyrene Reshapes the Food Packaging Track

Global renowned styrenics manufacturer INEOS Styrolution has proudly launched the innovative material Styrolution® PS 158K GR2 BC100, an ISCC-certified bio-based polystyrene setting a new benchmark for eco-friendly food packaging materials! Food packaging made from this material is now being used for food sold in Japanese markets.

BASF Elastollan® TPU Flat Traction Steel Belt: The Future of Elevator Performance and Safety

In traditional elevator systems, steel ropes have always been the standard configuration for traction systems. However, as buildings grow taller and the demand for space, energy efficiency, and safety becomes increasingly urgent, the drawbacks of steel ropes, such as the need for frequent maintenance, high energy consumption, and limited design flexibility, have become more pronounced. Nowadays, thermoplastic polyurethane (TPU) flat traction belts, with their characteristics of being lightweight, high-strength, and flexible, are redefining possibilities and driving the development of the new generation of elevator systems. They are particularly suitable for machine-room-less (MRL) designs, which require compact system integration and high-performance materials.

Editor: Lily

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track