Don't Miss the Essentials! Single Screw Extruder Uses and Maintenance Tips!

The domestic plastics industry generally classifies extruders into two types: single-screw extruders and twin-screw extruders. Today, let me introduce you to the applications and maintenance of single-screw extruders. Let's take a look together.

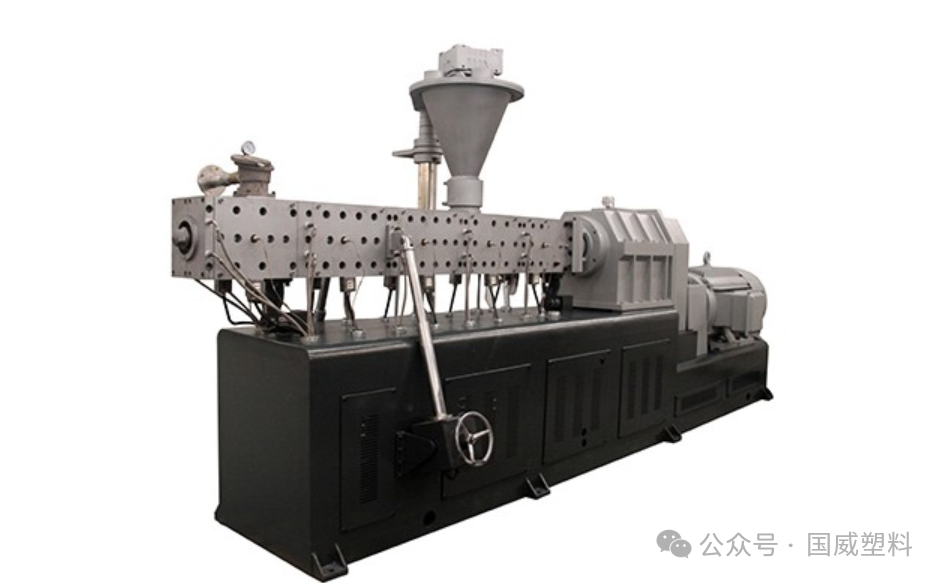

Introduction and Applications of Single Screw Extruder

(1) Introduction to Single Screw Extruder

As the name suggests, a single-screw extruder has one screw inside the barrel. Generally, the effective length of the screw is divided into three sections, which are determined based on the screw diameter, pitch, and depth. Typically, each section accounts for one third of the total effective length.

The section starting from the last part of the screw in the feed port is called the conveying section. In this area, the material should not be plasticized, but it needs to be preheated, compressed, and compacted. According to past extrusion theories, the material here was considered to be a loose body. However, it has been proven that the material is actually a solid plug, meaning that after being compressed, the material is like a solid plug. Therefore, its function is simply to complete the conveying task.

The second section is called the compression section. In this section, the screw groove volume gradually decreases, and the temperature must reach the level required for material plastification. Compression occurs here (from the third part of the conveying section, it can be compressed to one here, which is called the screw's compression ratio—3:1, although some machines may differ), and the plastified material enters the third section.

Section 3: Metering section. Here, the material is maintained at the plasticizing temperature and is accurately and quantitatively delivered to the die head like a metering pump. At this stage, the temperature must not be lower than the plasticizing temperature and is generally slightly higher.

(2) Application of single screw extruder

Single screw extruders are mainly used for the extrusion of pipes, sheets, plates, and profiles, as well as for the pelletizing of some modified materials.

(3) Maintenance of Single-Screw Extruder

① Due to the high requirements of the electrical control system for ambient temperature and dust prevention, the electrical system should be isolated from the production site, and ventilation or exhaust fans should be installed. It is recommended to place the electrical control cabinet in a simple room, keeping the room clean and ventilated, ensuring that the indoor temperature does not exceed 40°C.

② The single-screw extruder is not allowed to run without load to prevent the screw and barrel from being damaged. When the main engine is started for idle operation, it should not exceed 100r/min; when starting the main engine, begin at a low speed, and after checking for any abnormal noises, gradually increase the main engine speed to within the permissible range of the process (it is best if it can be adjusted to the optimal state). During the running-in period of a new machine, the current load should be 60-70%, and during normal use, the current should preferably not exceed 90%. Note: If any abnormal noise occurs during the operation of the extruder, it should be stopped immediately for inspection or repair.

③ Start the oil pump before starting the machine, and turn off the oil pump after shutting down; the water pump should remain operational throughout the entire production process and must not be stopped, to prevent the barrel temperature from rising and causing material decomposition and carbonization inside the barrel; the asbestos fan cover of the main motor fan needs to be regularly cleaned to avoid excessive dust accumulation that could block the fan cover, leading to insufficient motor cooling, overheating, and tripping.

4. Promptly clean off dust, tools, and debris from the surface of the unit.

⑤ Strictly prevent metal or other foreign objects from falling into the hopper to avoid damaging the screw and barrel. To prevent iron debris from entering the barrel, a magnetic component or magnetic rack can be installed at the material inlet of the barrel, and to prevent foreign objects from falling in, the material must be sieved in advance.

6. Pay attention to the cleanliness of the production environment to prevent debris and impurities from mixing into the materials, which could block the filter plate and affect product yield, quality, and increase resistance in the machine head.

The gearbox should use the lubricating oil specified in the machine's manual and be filled to the prescribed oil level. Insufficient oil results in inadequate lubrication, reducing the lifespan of parts; excessive oil leads to increased heat, higher energy consumption, and faster oil degradation, which also causes lubrication failure and damage to parts. Any leaking areas of the gearbox should have their seals (gaskets) replaced promptly to ensure the proper amount of lubricating oil.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track