Don't just know about high-temperature nylon! these 5 plastics can also withstand the test of fire

1. PPO (Polyphenylene Oxide)

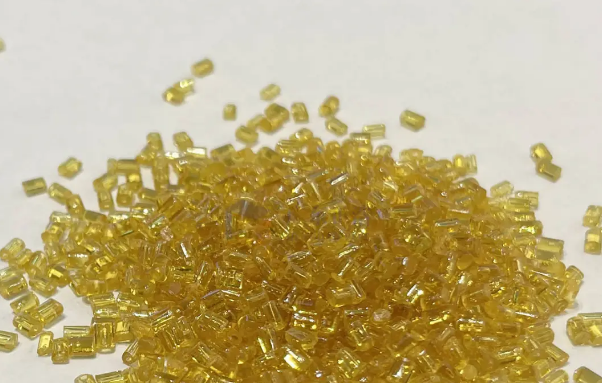

PPO is an amber-colored transparent material with a specific gravity of approximately 1.06, which is close to that of water.

- Combustion characteristics: flame retardant, extinguishes immediately after being removed from fire, produces thick black smoke when burning, and emits a floral and fruity smell in a molten state.

- Core Advantages:

-

It has the highest glass transition temperature (210°C) among thermoplastic materials, with outstanding high-temperature resistance. -

It can withstand boiling water and steam at high temperatures without deforming or decomposing. -

The material is hard and tough, with better creep resistance than PA, POM, and PC, and has a higher surface hardness. -

Excellent low temperature performance, maintaining good extensibility at -135℃ with strong dimensional stability. -

Excellent dielectric properties, stable across a wide range of frequencies, temperatures, and humidity. -

Supports metallization processes (electroplating or vacuum coating). - Main shortcomings: Exposure to organic solvents can easily lead to stress cracking; poor weather resistance, easily discolored by sunlight; poor fluidity, making processing difficult.

- Applicable scenarios: Suitable for environments that are humid and under load, requiring excellent dielectric performance and high mechanical performance, such as tuning plates, microwave insulation components, water treatment equipment, medical devices, food contact materials, and high rigidity electrical enclosures, with performance superior to PC.

- Injection Molding Key Points: Crystalline plastics, melting point at 217°C, decomposition temperature at 360°C, processing temperature usually between 280-340°C; requires drying treatment, drying at 140°C for 2-4 hours can remove moisture to avoid decomposition during processing.

In addition, although the modified product of PPO, NORYL, has significantly lower mechanical properties compared to PPO, its performance can rival that of PC and can be used as a substitute in certain scenarios.

2. PPS (Polyphenylene Sulfide)

PPS is naturally white, has high crystallinity, and is hard and brittle with excellent thermal stability, combining the high resistance of thermosetting plastics. It should be noted that pure PPS cannot be directly injection molded (it tends to partially cross-link at high temperatures, resulting in poor flowability). The PPS available on the market for injection molding is all modified products, with fillers and modifiers added.

- Combustion characteristics: non-combustible, extinguishes immediately after leaving the fire; produces a metallic "clinking" sound when struck together.

- Core Advantages:

-

Resistant to various solvent corrosion in high-temperature environments. -

The creep resistance is strong, and other mechanical properties are also relatively outstanding. -

Maintains mechanical properties and dimensional stability at high temperatures. -

Excellent dielectric properties, minimally affected by frequency, temperature, and humidity.

-

- The main drawbacks are poor impact resistance and brittleness.

- Applicable scenarios: Suitable for high-temperature, humid, and load-bearing environments, and can be used as insulation, anti-corrosion, and insulating materials.

- Key Points for Injection Molding: Crystalline plastic, melting point 280°C, decomposition temperature 400°C, processing temperature generally 300-340°C; hygroscopic, moisture will cause decomposition during processing, needs drying at 140°C for 2-4 hours.

3. PSF (Polysulfone)

PSF is mostly a transparent material with a slight amber tint (some are ivory-colored and opaque), with a medium specific gravity (1.24).

- Combustion characteristics: flame-retardant, extinguishes after removal from fire, with a flame accompanied by yellow-brown smoke, emitting a burnt rubber odor when melting during combustion.

- Core Advantages:

-

Outstanding high and low temperature resistance, maintaining 80% mechanical strength at 150°C and 75% mechanical strength at -100°C. -

Excellent creep resistance and long-lasting mechanical strength stability. -

High dielectric performance is strong, remaining stable at a high temperature of 190°C, as well as in water or humid environments. -

Outstanding radiation resistance. -

Supports metallization processing (electroplating or vacuum coating). - Main drawbacks: Although it is not easily hydrolyzed, water can cause stress cracking under high temperature and load conditions; it has poor fluidity and is difficult to process.

- Applicable Scenarios:

-

Manufacturing electrical and electronic components that require precise tolerances, high rigidity, thermal stability, and good electrical insulation. -

Parts requiring thermal performance, chemical resistance, durability, and rigidity. -

It is not easily hydrolyzed at low temperatures and can be used for parts of low-temperature water treatment equipment, pump components, water valves, washing machine accessories, etc. It performs better than PC when used as a high-rigidity housing material. - Key points of injection molding: The injection molding temperature is relatively high, ranging from 280-320°C; the injection molding conditions for modified PSF are similar to those of PC, and the drying temperature should also refer to the PC standards.

4. Polyarylate

Polyarylate is a transparent material, represented by the grade U-100.

- Combustion characteristics: flammable, self-extinguishing after removal from fire; produces a small amount of non-toxic smoke when burning.

- Core Advantages:

-

It has excellent heat resistance without fiberglass reinforcement. -

Self-extinguishing without the need for flame retardants, produces low and non-toxic smoke when burning, and meets safety specifications. -

Low thermal expansion coefficient, low creep, low hygroscopicity, resistant to acid and oil corrosion.

-

- Main drawback: not resistant to alkalis and organic solvents.

- Application scenario: Suitable for household appliance manufacturing due to its outstanding safety and stability.

- Key points of injection molding: Drying is required before processing, bake at 100-120°C for 4-6 hours; the injection molding temperature is 330-350°C.

5. Polyarylsulfone

Polyarylsulfone is a transparent material with a slightly higher density than polysulfone, with the representative product being Astrel 360.

- Core advantages: Heat resistance far exceeds PSF, with heat distortion temperature and continuous use temperature approximately 100°C higher than PSF; mechanical strength is similar to polysulfone.

- The main drawbacks are poor liquidity and high processing difficulty.

- Applicable scenarios: As a super high-temperature resistant material, it is suitable for special scenarios with extremely high requirements for temperature resistance.

- Injection Molding Key Points: The processing temperature range is 320-410°C, and the mold temperature should be controlled between 232-260°C. It has strong hygroscopicity and needs to be dried before processing. Drying at 260°C for 2-4 hours can ensure moisture removal.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track