Dongming Petrochemical: New "alkene" hope refined from crude oil

Shandong Dongming Petrochemical Group is one of China's top 500 enterprises. Against the backdrop of new energy disrupting the traditional refining and chemical market, the company adheres to technological innovation to drive industrial transformation and upgrading. Focusing on olefins as a breakthrough direction, it develops high-end chemicals and actively seeks to transition from a "refining-oriented" to a "chemical-oriented" business model.

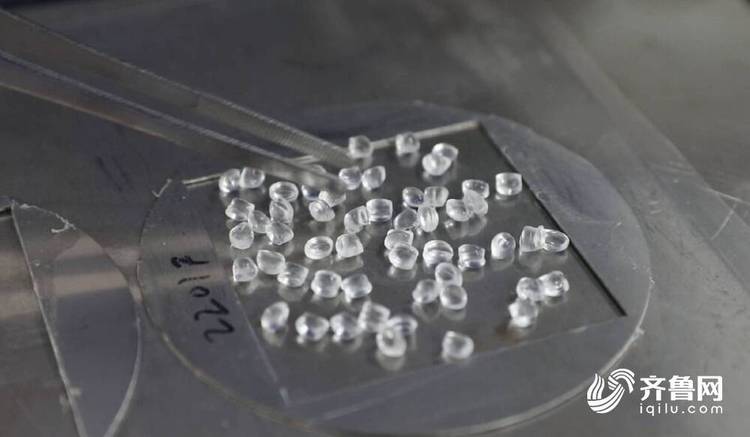

In the workshop of the 5,000-ton EPOE pilot project at Shandong Dongming Petrochemical Group in Heze City, the first batch of pilot products is being successfully produced. These small, transparent EPOE pellets are derived from black crude oil. Their successful production will promote the localization of polyolefin materials.

Dajian, the honorary president of Shandong High-end Chemical Research Institute, told reporters that EPOE, also known as ethylene polyolefin elastomer, is a kind of high-end chemical new material that can be used in photovoltaic, automotive, aerospace, wire and cable, biomedicine and other fields. The technology is completely with independent intellectual property rights. Compared with the previously foreign-dominated polyolefin elastomer materials, it performs excellently in mechanics, anti-UV, low-temperature toughness and aging resistance, and its application range is wider.

Dongming Petrochemical Group is currently the largest local refining enterprise in Shandong and even in China, processing about 10.5 million tons of crude oil annually, with an annual sales revenue of over 100 billion yuan. However, with the development and popularization of new energy sources in recent years, the overall production capacity of the national refined oil market has exceeded demand. The survival space for traditional refining is becoming smaller and smaller, making transformation an inevitable choice. But a drop of crude oil can be used to derive thousands of chemical raw materials and products in two major categories: olefins and aromatics. What is the focus for high-end chemical industry? Dongming Petrochemical possesses a technology that can directly convert crude oil into ethylene and propylene, which gives the company a sense of direction.

In this regard, Miao Zhenqi, Vice Chairman of the Board of Directors of Shandong Dongming Petrochemical Group, stated that after considering market demand, industry competition, and the company's advantages in upstream raw material reserves and ethylene-propylene products, among other aspects, the decision was made to pursue olefins as the development direction following thorough analysis. This approach allows for differentiated competition with petrochemical enterprises that adopt the aromatics-based technical route for textile production, both in terms of technology and downstream products.

To this end, Dongming Petrochemical invested funds, equipment, and technical personnel, and collaborated with Zhongke Kele Company, which has technology authorization from the University of Science and Technology of China, to build the world's first pilot plant with an annual production capacity of 5,000 tons of EPOE in less than ten months.

Shandong Zhongke Kole New Materials Company's technical director, Cheng Yuwen, told reporters that the biggest advantage of the EPOE process is that it uses only ethylene as a single raw material. This innovation significantly simplifies the production process. Compared to foreign technologies, it eliminates the need for high-cost imported high-carbon alpha olefins as the main raw material and avoids the construction of additional supporting facilities, greatly reducing production costs and operational risks of the equipment.

In recent years, China's import volume of polyolefins has grown at an annual rate of over 25%. Dongming Petrochemical's pilot project for the annual production of 5,000 tons of EPOE has successfully been industrialized, achieving import substitution for foreign polyolefin raw materials and creating a complete industrial chain of "crude oil - ethylene - EPOE high-end polyolefins" for the enterprise. Currently, a project for the annual production of 300,000 tons of EPOE is under construction, and it is expected to meet 30% of the domestic market demand upon production next year, potentially reducing foreign exchange expenditure by about 4.5 billion yuan annually for China.

Ding Shubing, Vice President of Shandong Dongming Petrochemical Group, stated, "To transform current market demands into our market share, we need to break through technological bottlenecks with innovation, fill the gaps in the domestic market, improve our product quality, and reduce production costs. Only by doing so can we truly capture the market."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track