Domestic High-End Material Breaks Through Again! 100,000 Tons/Year High-End Hot Melt Adhesive Grade HEV Facility Officially Completed

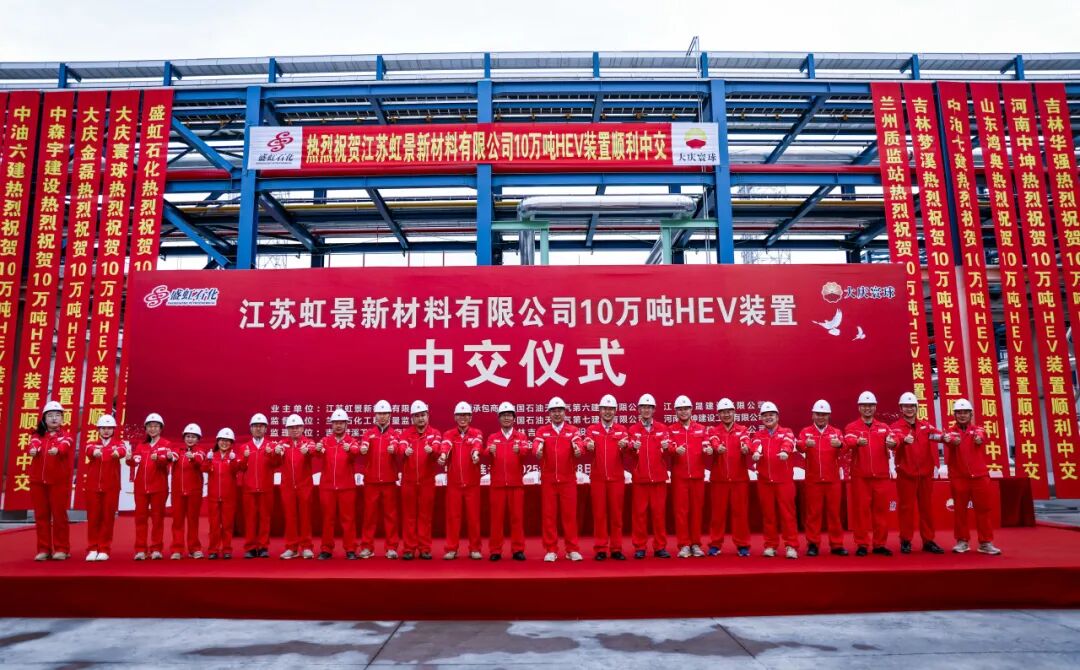

On September 28th, Jiangsu Hongjing New Material Co., Ltd. officially handed over its 100,000-ton/year high-end hot melt adhesive grade ethylene-vinyl acetate copolymer (HEV) unit.

The Jiangsu Hongjing 100,000-ton/year HEV project is located in the Xuwei New District of Lianyungang City, Jiangsu Province, with a total investment of approximately 2 billion yuan. It is a key project in the region focusing on high-end chemical materials. The project introduces the internationally advanced ECI kettle method process technology package, and upon completion, it will fill the domestic supply gap for high-end hot melt adhesive-grade HEV capacity.

On September 7, 2022, the groundbreaking ceremony for the Dongfang Shenghong Chemical New Materials Project was held at the Lianyungang Petrochemical Base. The Shenghong Chemical New Materials Project has a total investment of 21.6 billion yuan and is planned to produce 700,000 tons of EVA, 50,000 tons per year of copolymer new materials, as well as projects for PO/SM and polyols.

The Shenghong New Materials Project is divided into two parts: Hongwei and Hongjing.

The Hongwei section: Invested and constructed by Jiangsu Hongwei Chemical Co., Ltd., includes a POSM project, with the construction of a 508,000 tons/year ethylbenzene unit, a 200,000/450,000 tons/year POSM unit, a 112,500 tons/year PPG unit, and a 25,000 tons/year POP unit.

The Hongjing section: Invested and constructed by Jiangsu Hongjing New Material Co., Ltd., with a total investment of approximately 15.58 billion yuan, covering an area of about 1395 mu. It includes the construction of facilities with an annual production capacity of 3×200,000 tons of photovoltaic-grade ethylene-vinyl acetate copolymer (EVA), 100,000 tons of high-end hot melt adhesive-grade ethylene-vinyl acetate copolymer (EVA), high-end copolymer new materials, as well as utilities and auxiliary facilities.

As the core layout focusing on high-end chemical materials in Xuwei New District, this project has a total investment of 2 billion yuan. The main plant area covers 49,410 square meters, and the supporting finished product and packaging warehouse covers 18,900 square meters, ranking among the top in the country for similar installations. To tackle the technical challenges of high-end HEV production, the project introduces the internationally leading ECI kettle process technology package. By directly injecting cold ethylene into the cooling system, it achieves uniform product cooling, thereby preventing crystalline spots and fisheye defects from the source. Additionally, with an operating pressure range of 280 MPaG, it can produce high-end products with a narrower molecular weight distribution. The process safety has been verified by over 50 years of global industrialization.

This technology choice precisely aligns with the demands of the domestic market—currently, there is a long-term supply gap in the high-end HEV capacity in China's hot melt adhesive sector, and the overall import dependency of EVA materials has been over 50%. After the commissioning of this facility, it will effectively fill the market void and alleviate the "choking point" dilemma.

From pile foundation construction to the equipment handover, the project team achieved the implementation of all cycle milestones through precise management.

-

On November 26, 2023, the first pile foundation was successfully drilled, marking the beginning of construction.

-

On May 6, 2024, the pile foundation project was fully completed, laying a solid foundation for the civil engineering construction.

-

On October 22, 2024, the core equipment compressor was hoisted into place, and the equipment installation entered the fast track.

-

On April 2, 2025, the substation successfully received power, providing energy security for the operation of the equipment.

-

On June 11, 2025, a MRT test was completed, and the process system is ready for commissioning.

-

On September 28, 2025, achieve high standards in China Communications and successfully complete the construction phase objectives.

The Jilin Mengxi supervision unit and all participating subcontractors work together throughout the process, adhering to strict standards to control project quality, providing strong support for the high-quality advancement of the project.

Under the dual drive of the "dual carbon" strategy and the upgrading of the manufacturing industry, China's demand for high-end chemical materials continues to rise. This project is an important layout of Shenghong Petrochemical Industry Group in the high-end EVA field, forming a synergistic effect with the integrated refining and chemical base in the region, further improving the high-end chemical materials industry chain in East China. Currently, East China occupies a core share of the country's total EVA consumption, with high-end application demands such as hot melt adhesives concentrated in the area. After the project is put into production, it will achieve efficient matching of "production to sales" in the region.

With the advancement of subsequent production preparations, the facility is expected to quickly enter a stable operating phase, providing domestic high-end raw material guarantees for downstream industries such as automotive, packaging, and electronics, contributing to China's accelerated transition from a "chemical giant" to a "material powerhouse."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track