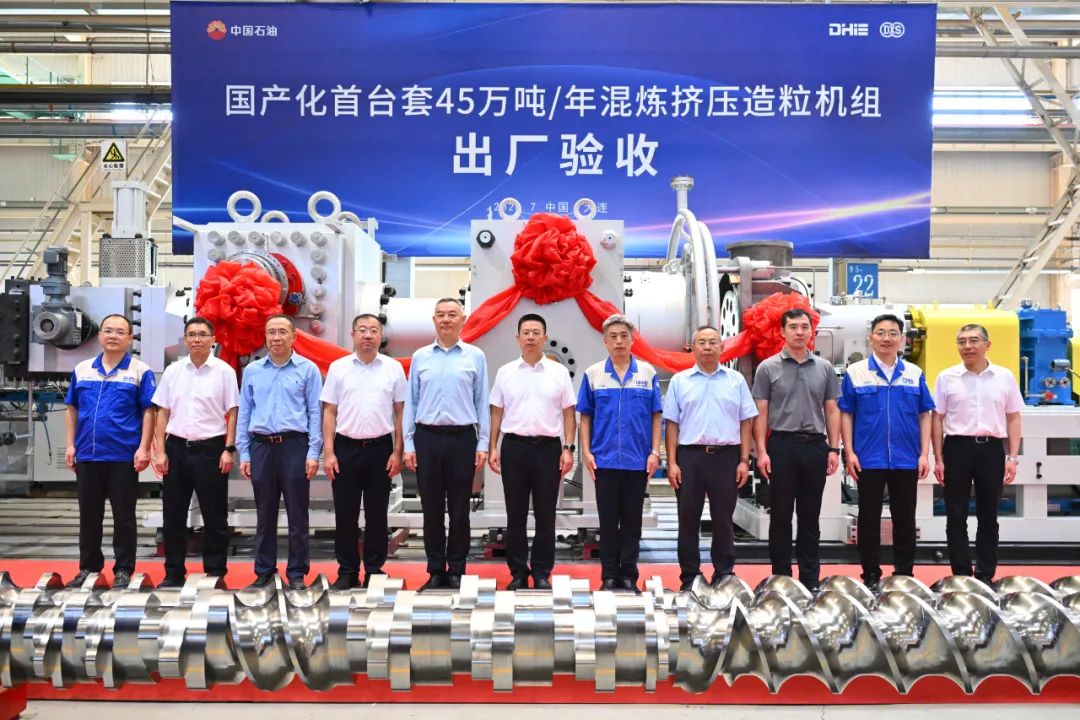

Domestic First 450,000 Tons/Year Polypropylene (PP) Compounding Extrusion Pelletizing Unit Passes Factory Acceptance Test

Building the "Nation's Heavy Artillery"Create maximum value for customers

Recently,CNPC Group Dushanzi Petrochemical CompanyTarim 1.2 million tons/year Phase II Ethylene ProjectThe domestically developed first set of 450,000 tons/year polypropylene compounding and extrusion granulation unit.Factory acceptance was completed at the Yingchengzi site of Dalian Heavy Industry Plastic and Rubber Equipment Group Co., Ltd.

Evaluated by the expert panel

The first domestically produced 450,000 tons/year polypropylene compounding extrusion pelletizing unit features a reasonable overall layout and good exterior quality; the technical indicators such as cold and hot state tests and performance tests of the unit all meet the requirements; the provided acceptance documents are complete and data reliable, conforming to the factory acceptance criteria, and the unit is hereby approved for release.

The Dushanzi Petrochemical Tarim 1.2 million tons/year Phase II ethylene project is a demonstration project by China National Petroleum Corporation to practice green and low-carbon development, leverage the integrated advantages of upstream and downstream sectors, and lead the high value-added comprehensive utilization of resources. It is a "model project" promoting the transformation and upgrading of refining and chemical businesses, achieving high-quality development. The large extrusion pelletizing unit is a key core equipment of the project, and its localization carries the strategic mission of solving the country's major equipment "bottleneck" issues. After 14 months of effort, the first set of 450,000 tons/year polypropylene compounding extrusion pelletizing machine was successfully delivered, while the other two 450,000 tons/year full-density polyethylene extrusion pelletizing machines have also entered the final assembly stage, making the last sprint toward unit delivery.

As China’s first domestic 450,000-ton-per-year polypropylene blended extrusion pelletizing unit, its development successfully overcame multiple technical challenges, effectively enhancing the unit’s advancement, stability, and reliability. This laid a solid foundation for the unit’s long-term optimal operation, significantly reducing costs compared to similar imported equipment and shortening the delivery cycle by more than six months. The delivery of this breakthrough product fills a domestic gap and fully demonstrates the company’s sense of responsibility and technical strength in advancing the localization of major core equipment. It marks a key milestone in China’s transition from “following” to “running alongside” in the design, manufacturing, and integration of large blended extrusion pelletizing units, and takes a crucial step toward “leading.” This achievement greatly promotes the independent development and localization of China’s high-end polyolefin major equipment, enhances the resilience and security of the national industrial and supply chains, and lays a solid technical and equipment foundation for subsequent large-scale ethylene and polypropylene projects in China. It holds significant industry-leading and exemplary value.

Leaders and expert teams from PetroChina Refining & Chemical Company and New Materials Company, PetroChina Materials Company, PetroChina Dushanzi Petrochemical Company, and Huanqiu Engineering & Supervision Company, relevant leaders from Dalian State-owned Assets Supervision and Administration Commission and Dalian Industry and Information Technology Bureau, leaders from Dalian Heavy Industry Equipment Group Co., Ltd., and cadres and employees from Dalian Rubber & Plastics participated in the unit's factory acceptance.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track