Dazzle pro unveils multi-laser and green light metal 3d printing equipment, highlights high cost-effectiveness, intelligence, and reliability

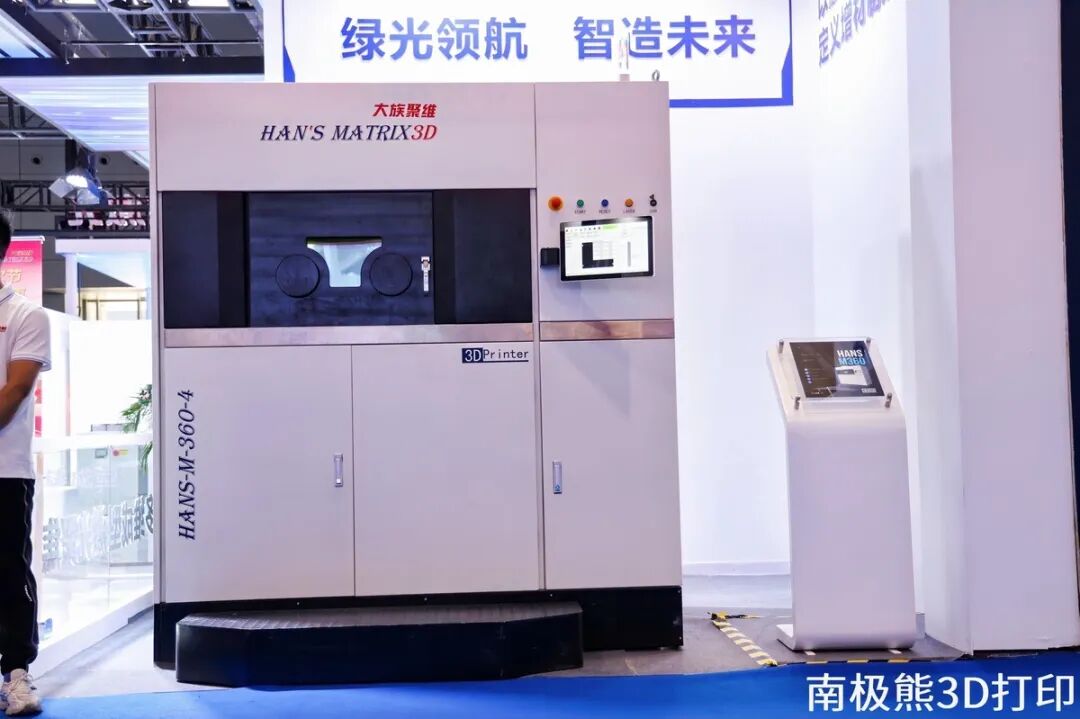

The booth of Han's Laser's subsidiary brand—metal 3D printing manufacturer Han's JuWei.

General Manager of Han's JWTang Jinglong stated that the two devices showcased at this exhibition both focus on high cost-effectiveness, intelligence, and safety and reliability, aiming to meet the diverse needs of customers across various industries, from prototyping and mold making to aerospace and new energy.

1. Emphasizing Intelligence and Openness: Dazzling Hans HANS M360-4 Multi-Laser 3D Printing Equipment

The first key device showcased is the HANS M360-4 by Han's Laser, a multi-laser metal 3D printer equipped with the latest intelligent system.

Core Highlights:

Intelligent Monitoring and Powder Spreading System: Equipped with a brand new intelligent monitoring and intelligent powder spreading system to ensure stability and efficiency in the printing process.

Fully Open Parameter Package: Adopts a fully open process parameter package, enabling users to conduct in-depth secondary development and process exploration with extremely high flexibility.

Advanced safety configuration: Optional permanent filter system significantly enhances the device's safety and reliability during the printing process, while reducing operational consumable costs.

Flexible Laser Configuration: Supports flexible configurations from dual laser to quad laser and is compatible with both imported and domestic lasers. Customers can choose based on their business needs and budget, offering outstanding cost-effectiveness.

Applications and Materials:

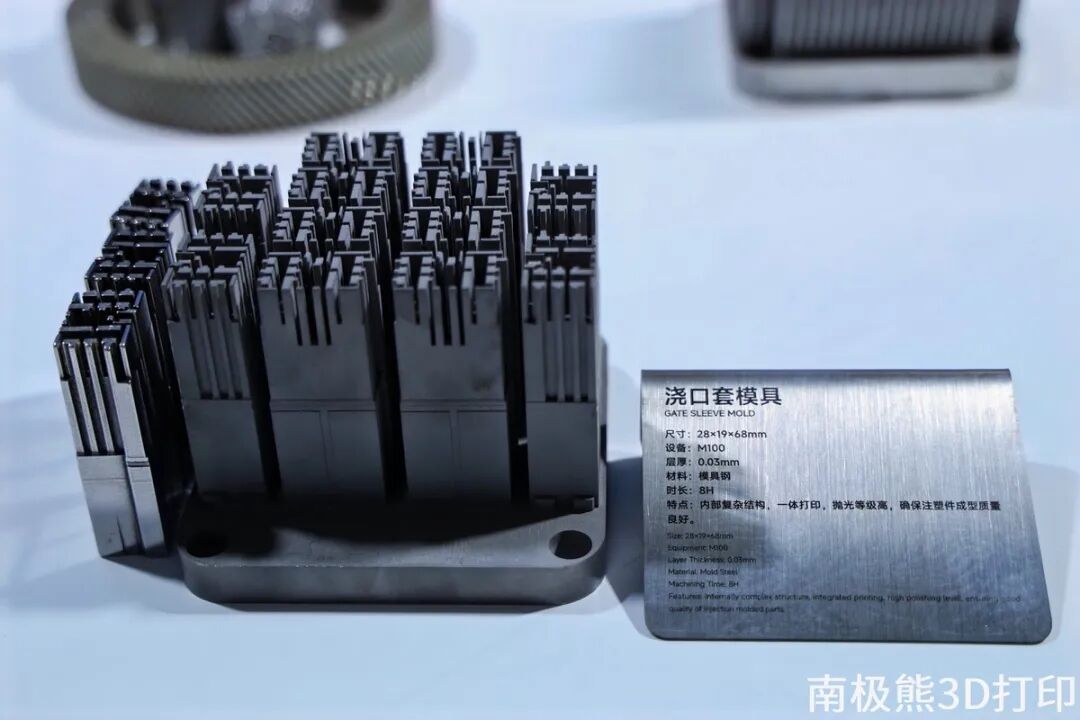

This device is ideal for printing figurine models, conformal cooling molds (such as shoe molds, inserts, gate sleeves), and aerospace components.

The range of processable materials is extensive, covering mainstream metal powder materials such as mold steel, stainless steel, titanium alloys, and high-temperature alloys. The exhibited exquisite dragon-shaped ornaments and gear parts also demonstrate its strong capabilities in the fields of complex structural components and crafts.

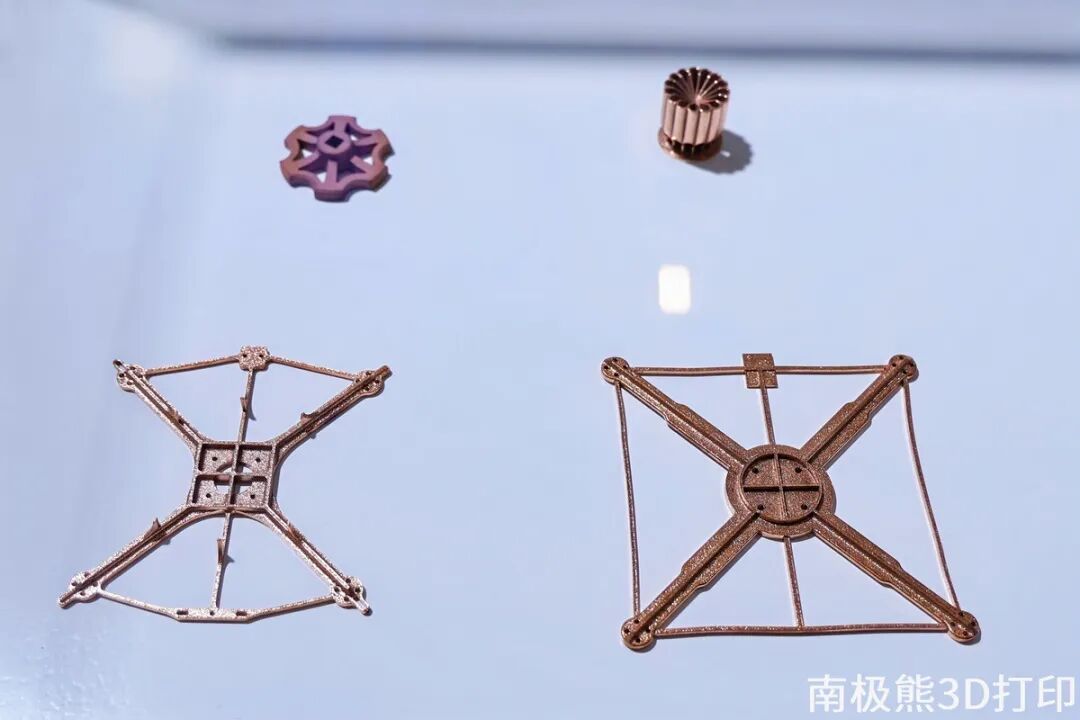

2. Specializing in Precision Manufacturing: Han's Guvin Green Light 3D Printing Equipment

Another significant product is the metal 3D printer equipped with a new generation green laser.

Core highlights:

Advantages of green light sources: Specifically optimized for high-reflection materials such as pure copper, effectively overcoming the energy reflection challenges faced by traditional infrared lasers when printing materials like copper and gold, achieving stable and efficient forming.

High-efficiency powder spreading design: The structure design of top powder supply and bidirectional powder spreading further enhances printing efficiency.

Intelligence and safety combined: Equipped with intelligent powder spreading detection function and has passed strict explosion-proof certification to ensure absolute safety during long-term operation.

Applications and Materials:

The device is an ideal choice for printing pure copper applications. A series of copper parts, including liquid-cooled heat sinks, heat fins, and flow guides, were exhibited on site, demonstrating its powerful capability in handling intricate and complex structures in the fields of heat exchange and dissipation.

3. Market Focus: Copper Material Applications Transitioning from Performance-Driven to Cost Optimization

In the interview, Nanji Bear specifically discussed the current popular trends in copper 3D printing applications with Tang Jinglong.

Tang Jinglong believes that the current applications of copper printing are mainly concentrated in fields such as new energy (e.g., battery heat dissipation) and thermal management (liquid cooling radiators), which require extreme heat dissipation performance and intricate complex flow channels. Customers are currently adopting this technology more out of an urgent need for performance enhancement rather than cost considerations. As large-scale mass production has not yet been achieved, copper printing does not have a cost advantage over traditional processes.

However, he is full of confidence about the future: "Driven by performance demands and leveraged by application volume," as market acceptance increases and the range of applications expands, the effects of mass production will soon lead to an overall reduction in costs, and the prospects for 3D printing applications of copper materials are very promising.

Dazu Juv's exhibition of two devices this time clearly demonstrates its market strategy: on one hand, it covers mainstream market demands with cost-effective and flexibly configured multi-laser devices; on the other hand, it tackles the growing market of high-reflectivity materials with new technologies like green light, particularly the hot copper applications in the booming new energy sector, showcasing its deep technical reserves and keen market insight.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track