Cutting-Edge Technology | Researchers Develop Non-Isocyanate Polyurethane (NIPU) Material for Implantable Medical Devices

A team of scientists from the University of Liège in Belgium has developed a new type of polymer called PHOx. This is a non-isocyanate thermoplastic polyurethane elastomer that can significantly improve the safety of implantable medical devices while being more environmentally friendly.

This achievement has been published in the scientific journal Advanced Healthcare Materials and an international patent has been applied for (WO2025082761).

Millions of patients worldwide undergo interventional or implantable medical device treatments for the cardiovascular system each year, including arterial and venous catheters, cardiac devices, pacemaker leads, artificial hearts, and vascular prostheses. These devices, often made of polyurethane (PU), serve important functions but have significant drawbacks: the production of polyurethane relies on toxic isocyanate chemicals and can easily cause serious complications such as thrombosis and infections in patients.

To this end, the teams from the Cardiology Laboratory (GIGA) and the Polymer Research Laboratory (CESAM) at the University of Liège have proposed a promising alternative: PHOx, a non-isocyanate polyurethane (NIPU) thermoplastic elastomer that not only involves a less toxic production process but also significantly improves biocompatibility.

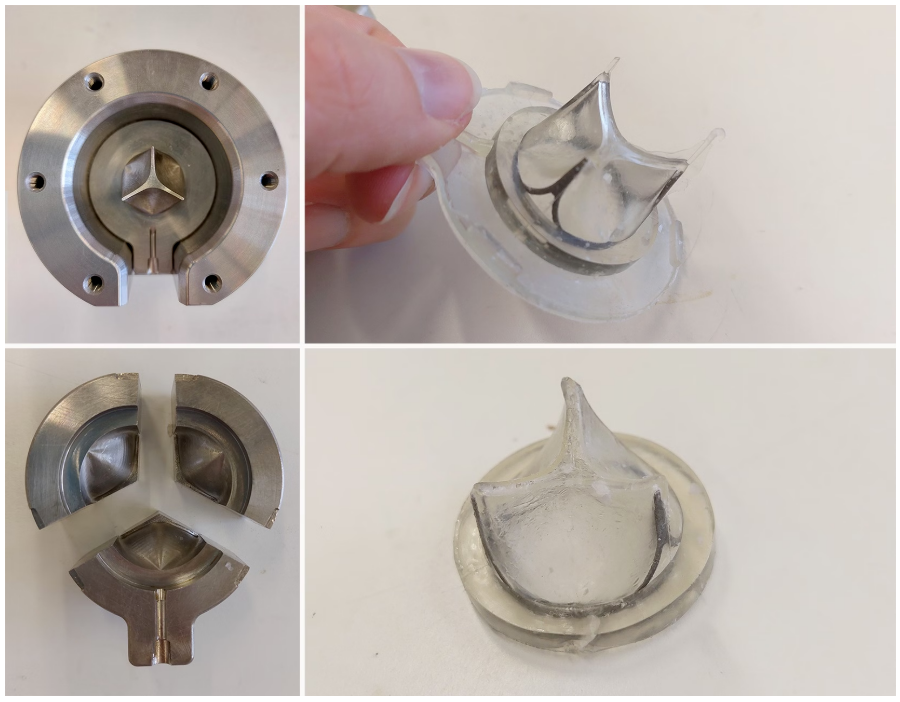

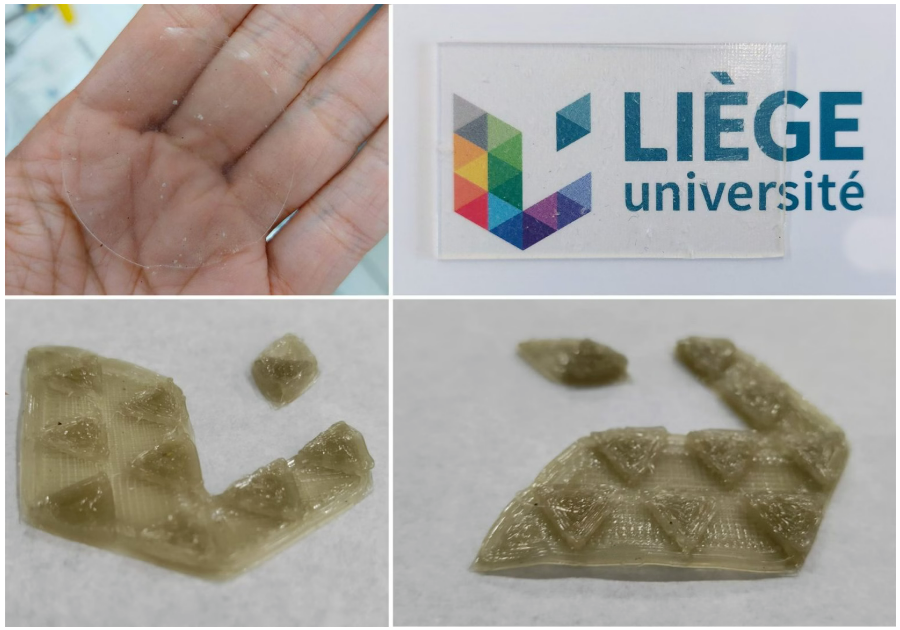

Chemists Anna Pierrard and Christine Jérôme, director of the Polymer Research Laboratory (CESAM) at the University of Liège, explained: "PHOx (polyhydroxyoxazolidinone) is a flexible and moldable plastic that contains cyclic carbamate bonds, allowing it to be molded, pressed, spun, and 3D printed. Therefore, it can be used to produce various personalized medical devices. Moreover, its raw materials are derived from environmentally friendly components sourced from carbon dioxide, significantly reducing its environmental footprint."

Sofia Melo, a bioengineer, and Cécile Oury, head of the Cardiology Laboratory (GIGA) at the University of Liège, stated: “A large number of laboratory tests have shown that PHOx outperforms conventional medical-grade TPU in several key aspects, with greater compatibility with blood. In particular, it can reduce the adhesion of platelets (the key cells in thrombosis) and the activation of coagulation, thereby lowering the risk of thrombosis. It is also believed to inhibit the adhesion of bacteria such as Staphylococcus aureus, which are often associated with implant infections. No toxicity has been observed for PHOx, either toward human cells or during implantation, and the material has not caused excessive inflammation, degradation, or rejection reactions.”

Another breakthrough advantage of PHOx lies in its suitability for 3D printing. This means that in the future, medical devices can be customized for patients at a lower cost while reducing waste. From personalized implants to anatomically adapted heart valves, the application scenarios of PHOx are extremely wide-ranging.

With its outstanding mechanical properties (flexibility and strength) and biological characteristics (biocompatibility, hemocompatibility, and stability), PHOx is expected to replace traditional polyurethane materials in multiple fields. This breakthrough advances medical devices toward greater safety, environmental friendliness, and cost-effectiveness—customized production combined with the reduction of complications will lead to multiple benefits through lower medical costs.

Researchers emphasize that this is the first time non-isocyanate polyurethane (NIPU) materials have demonstrated such excellent performance in critical medical applications.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics