Copolon Debuts at K 2025: Innovative Synergy in Plastic Recycling Technology

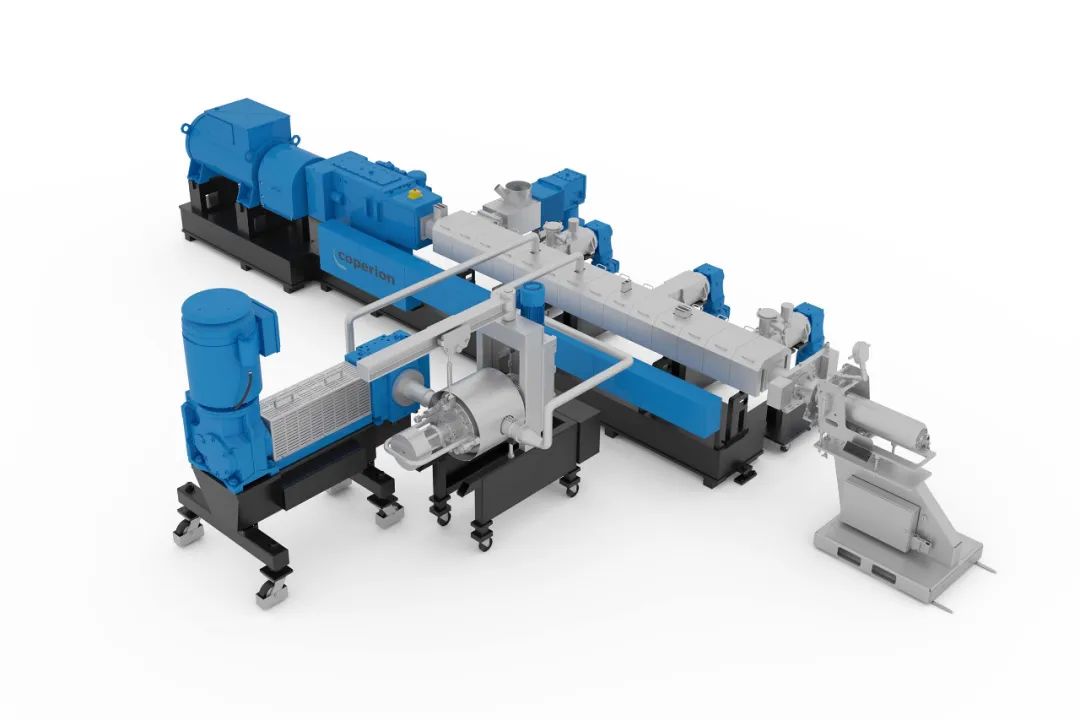

Coperion will jointly exhibit with Herbold Meckesheim at the K Trade Fair to be held in Düsseldorf, Germany, from October 8 to 15, 2025. At booth 9B34 in Hall 9, the focus will be on showcasing Herbold Meckesheim’s mechanical processing technologies for plastic waste, including the new T 150-300 mechanical dryer and the SMS 80-200 granulator. In the open-air area FG/CE07, visitors can witness the seamless collaboration of Coperion’s full range of recycling technologies, with exhibits including:

-

Herbold Meckesheim Hydraulic Cyclone Classifier -

ZSK FilCo Filter Mixing Extruder -

ZS-B MEGAfeed Side Feeder -

Kobelco Kaichuang K3-V200 Vibrating Feeder -

S60 Single Screw Feeder -

MechaTron® Flat Bottom Feeder -

Mobile Deodorization Device (for Removing Odors from Recycled Materials)

In addition, Copelon will showcase its core capabilities in plastic compounding technology at Booth 14B19 in Hall 14.

Efficient Collaboration between ZSK FilCo and ZS-B MEGAfeed

The open exhibition area FG/CE07 will demonstrate the new ZSK FilCo filter-compounding extruder, which can complete the recycling material filtration and compounding in one step. Compared to traditional two-step production lines, the ZSK FilCo handles materials more gently and significantly reduces energy consumption while improving product quality when recycling post-consumer waste plastics and other highly contaminated polymers. Waste plastics (such as recycled pellets, fiber scraps, film fragments, or untreated agglomerates) are melted, homogenized, and degassed through the ZSK twin-screw extruder. After impurities are removed by a screen, additives are injected before granulation.

To fully leverage the performance of ZSK FilCo, a stable supply of raw materials without feeding restrictions is required. Traditional granulation or compaction processes have high energy consumption and increase costs, whereas the showcased ZS-B MEGAfeed side feeder can reliably convey lightweight materials with bulk densities as low as 20 kg/m³ (such as fibers and flakes), enabling high-throughput recycling.

Seamless integration of material handling and feeding technology

Coperion's high-precision feeding technology representative exhibits include:

-

PK3-V200 Vibratory Feeder: Suitable for precise metering and feeding of challenging materials such as small granules or flakes. -

Mecha Tron FB flat-bottom feeder: specially designed for lightweight and difficult-to-feed materials such as polypropylene/PET films. -

S60 Single Screw Feeder: Renowned for High Reliability

In addition, the ZRD rotary valve, developed by Coperion specifically for plastic recycling, ensures reliable discharge of flakes through new drive technology and rotor-to-housing gap design.

The K-Tron K3 vibratory feeder is equipped with a unique drive system, suitable for high-precision feeding of recycled materials.

One-stop integrated solution for self-produced products

At K 2025, Coperion will demonstrate the synergistic effects of its technology through 3D simulations. The audience will gain an in-depth understanding of the operation of complete systems and the functions of each individual component. All components and technologies from Coperion feature high output, high-quality end products, and exceptional efficiency. For instance, Coperion recently successfully commissioned chemical plastic recycling production lines at two customer plants, each with a processing capacity of up to 6,000 kg/h.

With the recently installed "EcoFresh Silo Devolatilization Unit" at the Recycling Innovation Center, Cobelong is able to conduct devolatilization performance tests on customers' actual products under conditions close to real production, allowing for evaluation before production starts.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track