Coperion Debuts at K2025: Efficiency Upgrades for Compounding and Recycling Processes with ZSK and STS Twin Screw Extruders

Improving efficiency is the core focus of Coperion's research and development work in the twin-screw extrusion field. Coperion's appearance at the K Fair 2025 will also emphasize enhancing mixing and recycling efficiency. At booth 14B19 in Hall 14, Coperion will showcase a ZSK 58 Mc.18Twin-screw extruder. This extruder has a screw diameter of 58mm and features low energy consumption and high automation, capable of achieving a production capacity of up to 2,500 kg/h. In addition, Kebelon will also showcase an STS 35 Mc at the same booth.11The twin-screw extruder has been specially optimized for masterbatch production. At the Recycling Pavilion FG/CE07 in the open area, Coperion will demonstrate the added value of its twin-screw extruder in plastic recycling applications. Also on display will be the patent-pending ZSK FilCo filter-compounding unit.

ZSK and STS: Proven High-Performance Extruders

The ZSK and STS twin-screw extruders from Coperion excel in high performance. Both extruders feature a very high specific torque - ZSK Mc.18The torque ratio is 18 Nm/cm.3;STS Mc11The specific torque is 11.3 Nm/cm.3The torque is transmitted directly to the twin screws in the processing section through the gearbox and screw spindle, allowing for very high production rates in an economical and efficient manner when processing products with torque requirements. Additionally, due to the high filling rate in the processing section, the mixing quality is also outstanding. Combined with the high level of automation in these two extruder series, the unit cost for blending modification is relatively low, resulting in a quicker return on investment. These extruders are very durable, with high equipment stability, uptime, and OEE (Overall Equipment Efficiency).

Coperion will showcase the ZSK 58 Mc equipped with new screw elements.18The extruder, these threaded components were specifically developed by Kebelong for processing fillers. These threaded components can reduce wear in the melt zone while increasing output.

In terms of compounding and recycling, the Coperion ZSK 58 Mc18The twin-screw extruder, with its numerous innovative features, offers exceptional product quality and very high output.

The STS 35 Mc exhibited this time.11The extruder is particularly suitable for the production of masterbatches. It can achieve a production capacity of up to 300 kg/h. The closely intermeshing twin screws ensure absolute uniform distribution of the materials while ensuring effective self-cleaning of the processing section. The compact design and smooth machine surfaces make cleaning and maintenance during formula changes very easy. STS 35 Mc11It stands out for its very high process stability and attractive cost-effectiveness. It will be showcased along with a Coperion AccuRate® Series 602 volumetric feeder.。

C-BEYOND Lifecycle Manager: Providing Predictive Maintenance for Coperion Extruders

Coperion has expanded itsC-BEYOND is a digital platform used to capture and display the operating data of extruders. C-BEYOND can obtain real-time assessments of key performance indicators (KPIs) such as equipment availability, output, and product quality. The production process is documented in detail, and the energy consumption and carbon dioxide emissions per kilogram of blended material can also be calculated. In the Overall Equipment Effectiveness (OEE) tool, the efficiency of the production line is displayed in real-time, allowing operators to quickly respond to deviations.

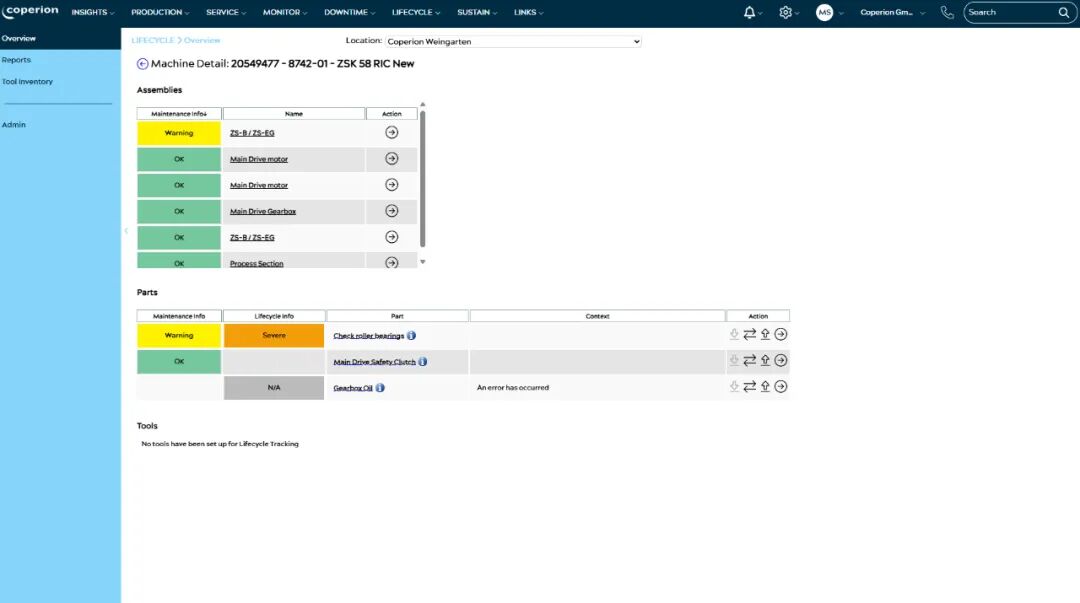

Coperion has expanded its digital platform C-BEYOND by adding a lifecycle manager, which is capable of notifying in advance about upcoming maintenance tasks for all components of the ZSK extruder.

C-BEYOND's new feature is the Lifecycle Manager, a component capable of enabling predictive maintenance scheduling to improve the production line's OEE. In the Lifecycle Manager, upcoming maintenance and repair tasks for all components of Coperion extruders are calculated based on operating hours and performance, and reports are generated in advance. For example, if gearbox maintenance is due soon, C-BEYOND will trigger a notification.

With the use of a lifecycle manager, maintenance and care work can be easily integrated and scheduled in advance, minimizing the impact on the high productivity of Coperion extruders. Once successfully executed, any maintenance measures are recorded in C-BEYOND and can be viewed at any time, accompanied by reports. As a result, a detailed maintenance history is generated for each machine during its service life.

The lifecycle manager has proven its effectiveness in practice on multiple pilot devices. Through this new tool, customers of Koberlin have already been able to significantly improve the overall equipment efficiency of their machines.OEE)。

Status Monitoring System: Real-time Monitoring of ZSK Extruder Operating Conditions

Coperion will showcase its new extruder condition monitoring system for the ZSK 58 Mc at the K Show.18By utilizing motors, gearboxes, and sensors on the processing section, the system continuously monitors the vibrations of the extruder and gearbox, as well as the condition of the lubricants. It detects the first anomalies in operation at an early stage. Within the scope of the service agreement, KEBILON is responsible for remotely monitoring and evaluating the collected data, providing action recommendations to achieve proactive maintenance and reduce unplanned downtime. The condition monitoring system can be integrated into both new and old machines and has proven its reliability in numerous applications.

ZSK Recycling Extruder: Recombination of High Product Quality

In the open area of the recycling pavilion FG/CE07, the ZSK extruder exhibited by Coperion is suitable not only for compounding but also for plastic recycling. Compared to the single-screw extruders commonly used in the plastic recycling industry, the ZSK twin-screw extruder stands out with its very strong mixing performance, excellent devolatilization capability, and high mechanical energy input, which shortens the residence time in the processing section. The product handling is very efficient and gentle. It achieves excellent product quality in the recycling of post-consumer mixed waste and industrial waste such as edge trims or sprues, with a throughput of up to 25 t/h.

These achievements are already being recovered.The quality of EPS foam has been confirmed in these aspects. The ZSK twin-screw extruder produces top-quality EPS—up to 30% of recycled EPS material can be added during the EPS production process without affecting the final product quality. Similar achievements have also been realized in Coperion's food-grade bottle-to-bottle recycling line, where the recycled and pelletized PET undergoes solid-state polycondensation (SSP) in a reactor—a process that has been approved by the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) for direct food contact and has been certified by major beverage brands. One of Coperion's bottle-to-bottle recycling demonstration plants uses the ZSK 133 Mc.18The extruder has a production capacity of up to 6500 kg/h. With Coperion's solution, the production capacity can reach up to 10 t/h. Through the ZSK FilCo, Coperion will showcase its specially designed recycling extruder: this filtration and compounding unit can achieve filtering and modification of recycled materials in a single process step and single-stage equipment. Compared to the two-step method and two-stage equipment, the required space is significantly less. The plastic only needs to be melted once during the recycling and modification process, making the production process more energy-efficient and the product quality superior.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track