Common Anti-Aging Methods for Plastic Materials and Comparative Analysis

Polymeric materials have indeed become essential in every aspect of modern life, and the latest advances in their production and processing have further expanded the application range of plastics. In certain applications, polymeric materials have even replaced other materials such as glass, metal, paper, and wood.

The inherent structural characteristics and physical state of polymer materials, along with external factors such as heat, light, thermal oxygen, ozone, water, acids, bases, microorganisms, and enzymes encountered during use, can lead to a decline or loss of performance in applications. This may manifest as yellowing, a decrease in relative molecular weight, surface cracking of products, and loss of gloss. More seriously, it can result in a significant reduction in mechanical properties such as impact strength, tensile strength, and elongation, thereby affecting the normal use of polymer materials.

This phenomenon is referred to as aging. Aging can occur at various stages of the synthesis, storage, processing, and final application of polymer materials, potentially leading to the end of the material's service life, resulting in significant waste of resources and severe environmental pollution. The aging of polymer materials during use is even more likely to cause catastrophic and irreparable losses.

Therefore, the anti-aging of polymer materials has become a problem that the polymer industry must address. In fact, the anti-aging of polymer materials is an important topic in polymer chemistry. Currently, there are four main methods to improve and enhance the anti-aging performance of polymer materials:

1. Physical protection (such as thickening, coating, outer layer composite, etc.)

The aging of polymer materials, especially photochemical and oxidative aging, begins at the surface of the material or product, exhibiting signs such as discoloration, chalking, cracking, and a decrease in gloss. It then gradually penetrates deeper into the material. Thin products are more prone to early failure compared to thick products; therefore, increasing the thickness of the products can extend their service life.

For products that are prone to aging, a layer of weather-resistant coating can be applied to their surface, or a layer of weather-resistant material can be compounded on the outer layer of the product, thereby adding a protective layer to the product's surface and delaying the aging process.

2. Improve the processing technology.

Many materials also face aging issues during synthesis or preparation processes. For example, the impact of heat during polymerization and thermal oxidative aging during processing. Accordingly, the influence of oxygen can be mitigated by adding deoxygenation devices or vacuum systems during polymerization or processing.

However, this method can only ensure the performance of the material at the time of production, and it can only be implemented from the source of material preparation, unable to address the issue of aging during reprocessing and use.

3. Structural design or modification of polymer materials

Many polymer materials contain groups in their molecular structure that are prone to aging. Therefore, through molecular structure design of the materials, replacing the easily aging groups with those that are less prone to aging can often yield good results.

Add anti-aging agents

Currently, an effective way to improve the aging resistance of polymer materials is to add anti-aging additives, which are widely used due to their low cost and the fact that they do not require changes to existing production processes. The main methods for adding these anti-aging additives are as follows:

Additive Direct Addition Method

The anti-aging additives (powder or liquid) are directly mixed with resins and other raw materials, then extruded and granulated or injection molded. This method of addition is simple and convenient, making it widely adopted by pelletizing and injection molding factories.

(2) Anti-aging masterbatch addition method

Manufacturers with high demands for product quality and stability more often use the method of adding anti-aging masterbatches during production.

The application advantage lies in the fact that the anti-aging agent is initially pre-dispersed during the preparation of the masterbatch. In the subsequent material processing, the anti-aging agent undergoes secondary dispersion, achieving uniform dispersion within the polymer material matrix. This not only ensures product quality stability but also avoids dust pollution during production, making the process more environmentally friendly.

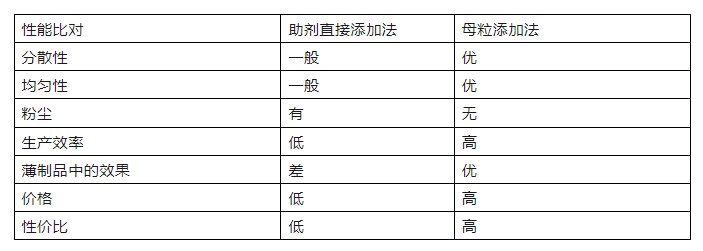

The comparison of the two addition methods is shown in the table below:

Based on the above analysis, we recommend using anti-aging masterbatches as much as possible when applying anti-aging additives to improve the quality of the material.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track