China's Plastics Machinery Industry Accelerates Going Abroad, Shifting From "Selling Products" To "Localized Ecosystem" Development

Introduction: The outbound strategy of China's plastic machinery industry is undergoing profound changes. According to data from the China Plastics Machinery Industry Association, in 2024, China's leading plastic machinery enterprises...The export value reached 13.5 billion yuan., with a year-on-year growth of 23.85%, significantly higher than the overall sales revenue growth rate of the industry.

From initially exporting simple equipment to establishing overseas after-sales service centers and then setting up factories for localized production, Chinese plastic machinery companies are no longer content with merely selling products overseas."Deep Localization" StrategyRoot and grow in the international market.

Haitian International: A Global Pioneer in Scale and Network

As the world's largest manufacturer of injection molding machines, Haitian International's overseas strategy is to...Build a global production and service network.It is a typical example of "manufacturing in China, manufacturing for the world."

"Integrated production, sales, and service overseas layout"Haitian International has gradually been in.India, Mexico, Germany, Turkey, VietnamFive overseas factories have been built in these regions. This model of "establishing factories directly in major markets" allows the company to stay close to customers, circumvent trade barriers, and quickly respond to market demands. Its overseas revenue now accounts for 40%, demonstrating significant success in globalization.

Haitian India Factory Exterior

Deeply penetrate regional markets.In advantageous markets such as Southeast Asia, Haitan International's market share exceeds 50%. The key to its success lies in...Deeply bind downstream Chinese-funded enterprises going abroad.For example, through its subsidiary in Thailand, it has provided long-term, stable equipment support and after-sales service for the Haier Thailand Industrial Park, establishing a trust transfer from a Chinese brand to a global brand.

Technology and brand dual driversIn addition to its main brand "Haitian," its high-end brand "Changfei Ya" has successfully entered high-end markets such as Europe with its advantages in fully electric and intelligent technology, changing the market's inherent impression of Chinese manufacturing as "low price and low quality."

Izhimi: A Global Pioneer Driven by Technology and Brand

The globalization path of Yizhi Mi focuses more on.Through technology integration and brand upgrading, penetrate the high-end markets in Europe and America....while simultaneously covering emerging markets with localized production.

Focus on Europe, Research and Development FirstYizumi regards Europe as a strategic stronghold, establishing a research and development center in Germany and collaborating with local universities and research institutions to absorb top-notch technology and enhance brand recognition.

Yizumi Germany R&D Center

Dual Branding and Global Production StrategyThe company has implemented a dual-brand strategy consisting of the main brand "YIZUMI" and the North American acquired brand "HPM," accurately targeting different customer groups. In coordination with this, the company has established a "China, Europe, America, India" integrated manufacturing framework globally. Through localized setups in China, Germany (R&D center), the United States (HPM production base), and India, the company has achieved deep penetration and rapid response in key markets.

Develop products with a targeted approach.In the Indian market, Yizhiming quickly developed specialized machine configurations to meet local demands. Its three-board machine, high-speed packaging systems, and other products have achieved excellent performance due to their high cost-effectiveness and localized services.

Jinwei Machinery: A Global Upgrader with Gradual Deepening

Compared to the all-encompassing of Haitan and Yizhim, Jinwei Machinery adopts a more incremental global strategy, with its core being"Service first, manufacturing follows."。

Step-by-step implementation of a composite base construction planThe globalization of Jinwei Machinery is divided into two stages: the initial stage involves setting up after-sales service centers in key markets, integrating parts warehousing, technical support, and regular inspection functions; after the market matures, it upgrades to a composite base of "service center + factory," achieving seamless integration of localized production and customized services.

Emphasize regional "adaptability"In the Eurasian region, where the industrial base is solid, accelerate the establishment of service outlets by relying on the mature industrial chain; upgrade product performance in advance in response to environmental standards and technical specifications in the European market; in fast-growing regions such as Southeast Asia and the Middle East, simultaneously promote the construction of service centers and market research to pave the way for the subsequent selection of manufacturing base locations. For cost-sensitive demand in Southeast Asia, optimize production processes and service packages. This differentiated pace highly aligns with industry trends.

Jinwei Machinery Vietnam After-Sales Service Center

Jinwei Machinery Vietnam After-Sales Service Center

Distributed Layout ModeJinwei's layout has, adopting a distributed layout of "regional manufacturing hubs + localized manufacturing units," which is becoming the mainstream choice for Chinese plastic machinery enterprises.

Haitian, Yizumi, and Jinwei's strategic upgrades collectively reflect the profound changes in Chinese manufacturing going global: shifting from scale expansion to quality cultivation, from price competition to value competition, and from "going out" to "going in."

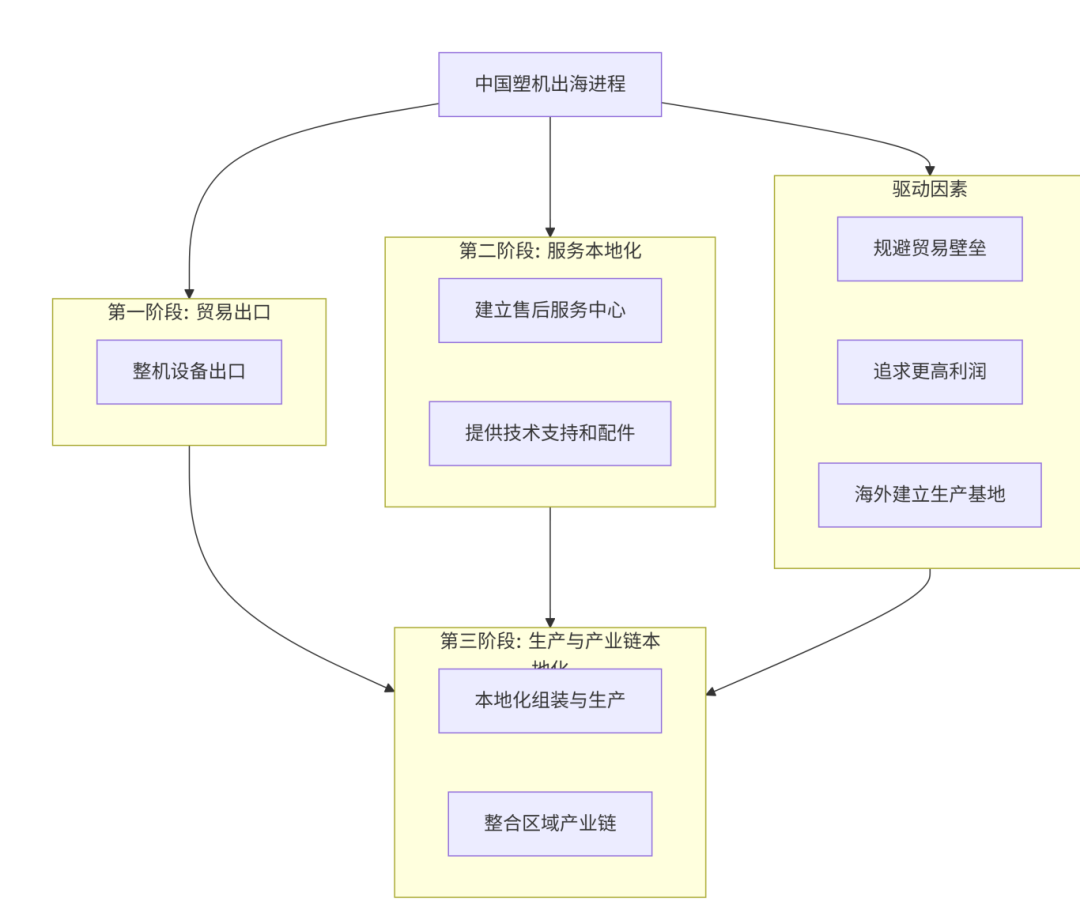

The export of Chinese plastic machinery has undergone an evolution from simple exports to deep localization. Initially, companies mainly exported products overseas through trade; subsequently, they began to establish sales networks and after-sales service systems abroad. Today, leading companies have directly built factories overseas, achieving localized production and services.

From Trade to Service Localization:

In the early days, companies mainly participated in trade fairs such as the Canton Fair.Complete equipment exportSubsequently, to enhance competitiveness, the company began to establish itself in the target market.After-Sales Service CenterIntegrate accessory warehousing, technical support, and regular inspection functions to streamline the "last mile" service chain. For example, while setting up a factory in India, Borle Injection Molding Machine also strengthens local service capabilities through its subsidiary.

Image Source: Bole Intelligence

Deep Localization - Production and Supply Chain Collaboration:

Establishing overseas production bases: Leading companies are moving quickly. Haitian International has already established production capacity in India and Mexico, and is building new capacity in Japan, Serbia, and other locations. Lesso Technology has set up production bases in several countries including the United States, Indonesia, and Thailand. At the same time, they are steadily advancing the preparation work for building production bases in Vietnam, the Philippines, Bangladesh, and other countries based on market capacity.

Image Source: Southern Industry Think Tank

Industry Chain Collaborative Going Abroad:

The overseas expansion of plastic product companies like Liansu Technology has also created opportunities for upstream plastic machinery equipment manufacturers to go abroad. After Liansu establishes production bases overseas, its procurement and maintenance of production equipment will naturally generate localized demands, providing conditions for plastic machinery companies to follow their downstream clients in going overseas.

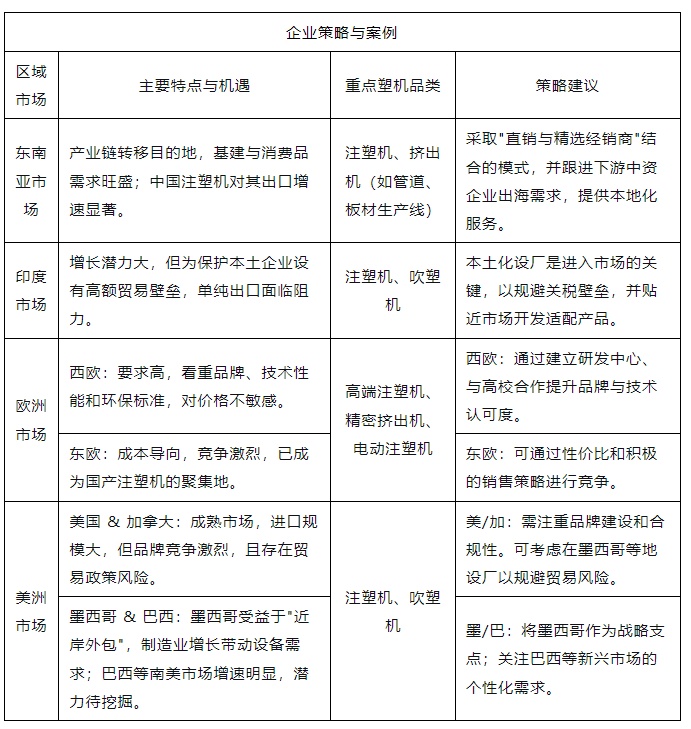

For Chinese plastic machinery companies planning to go global or already venturing abroad, deeply understanding the characteristics of different regional markets and adopting differentiated strategies that match them is the key to success.

Chinese plastic machinery companies, in the process of globalization, have explored various effective localization strategies based on the characteristics of different regional markets, forming a wealth of practical experience.

In terms of expansion in emerging markets,The company has demonstrated a high degree of flexibility and innovation. Taking the Cambodian market as an example, JSK Yonghua Company addressed the local issue of unstable voltage by developing a special stabilizing mechanism with their technical team, effectively ensuring production precision. At the same time, the company keenly identified the strong demand for preform production in the area and promptly provided customized injection molding machines, successfully entering the market. In the Indian market, Yizumi Company invested 100 million yuan to build a factory, establishing a localized production base and service platform, and quickly developed specialized machine configurations to meet the unique needs of the Indian market. Their three-platen machines and high-speed packaging systems have all achieved good performance.

Image source: Yizumi official WeChat account

In terms of tackling mature marketsThe company has adopted a differentiation strategy. Yu Jin Plastic Machinery has avoided the "price war" of traditional screws in the European and American markets, focusing on high-end screws required by industries such as medical and optics. The added value of these products is more than five times that of traditional products, and they have won a stable clientele in Europe and America with reliable quality.

Southeast Asian market as a key region.Toshiba Company has strategically positioned its electric injection molding machines as a breakthrough, successfully entering the Thai and Vietnamese markets with outstanding machine performance and gaining high recognition from local customers. Fuqiangxin Company has established direct overseas channels by setting up subsidiaries in Indonesia and Thailand, as well as offices in the Philippines and Vietnam, achieving a transformation from "agency" to "regular army" operations, greatly strengthening its sales and service capabilities. In terms of diversified layout, Fuqiangxin Company has implemented product specialization in its factories located in Taiwan, Dongguan, and Ningbo, with Ningbo focusing on medium to large machines, while standardizing blueprints and supply chains for cost reduction and efficiency improvement. The company has also positioned its Indian factory as a foothold in emerging markets and is attempting to build an integrated platform to provide customers with one-stop purchasing services.

Particularly noteworthy isThe innovative model of the entire industrial chain going overseasJiahe County, by attracting whole machine assembly enterprises and supporting enterprises such as Shidai Zhongtian, is striving to build the third largest injection molding machine manufacturing industry cluster in the country. The local government provides comprehensive services to ensure that enterprises can quickly settle and commence production. At the same time, online expansion also shows great potential. Under the organization of government departments, the Zhoushan screw cluster led 40 plastic machine screw companies to participate collectively in online exhibitions. They engaged in "one-on-one" video meetings with South Asian buyers, showcasing themselves as a regional brand and effectively expanding their international "circle of friends."

These vivid examples demonstrate that Chinese plastic machinery companies are transitioning from simple product exports to deep localized operations and global resource integration, providing the industry with diversified paths for international expansion.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track