Chemical Recycling and Life Cycle Assessment of Biodegradable Plastic PBAT: Current Status, Challenges, and Prospects

Abstract: This article reviews the current status, challenges, and future prospects of the chemical recycling of poly(butylene adipate-co-terephthalate) (PBAT). Through techniques such as hydrolysis, alcoholysis, thermochemical recycling, and biocatalytic recycling, PBAT waste can be converted into basic chemical components, achieving resource circularity. Additionally, a lifecycle assessment (LCA) of PBAT chemical recycling is analyzed, exploring the environmental and economic benefits of different recycling technologies. Furthermore, the role of policies and regulations in promoting PBAT chemical recycling is discussed, along with the challenges currently faced. Finally, the article looks ahead to the development potential of PBAT chemical recycling technologies, emphasizing the importance of technological innovation, market incentives, and policy support in advancing the PBAT chemical recycling industry.

Keywords: Poly(butylene succinate-co-butylene terephthalate); chemical recycling; biodegradable plastics; environmental impact; circular economy

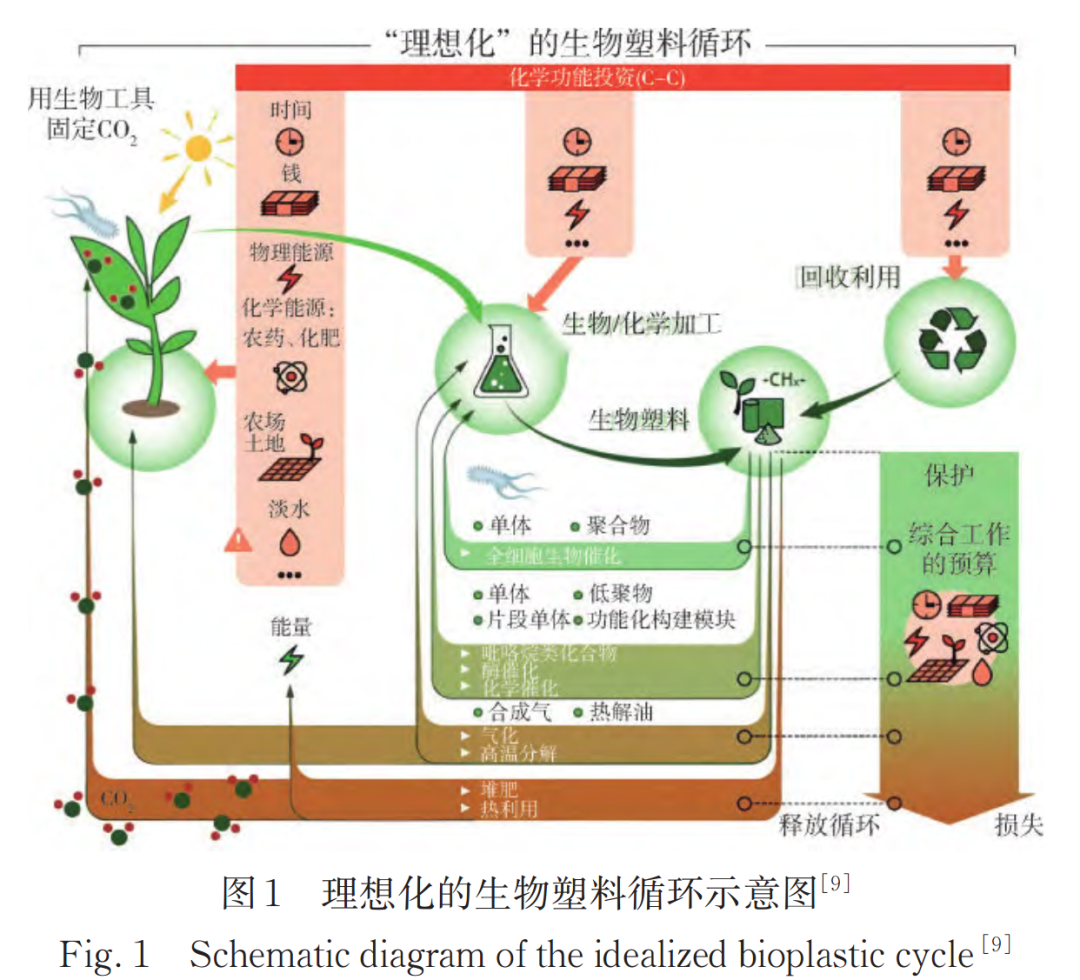

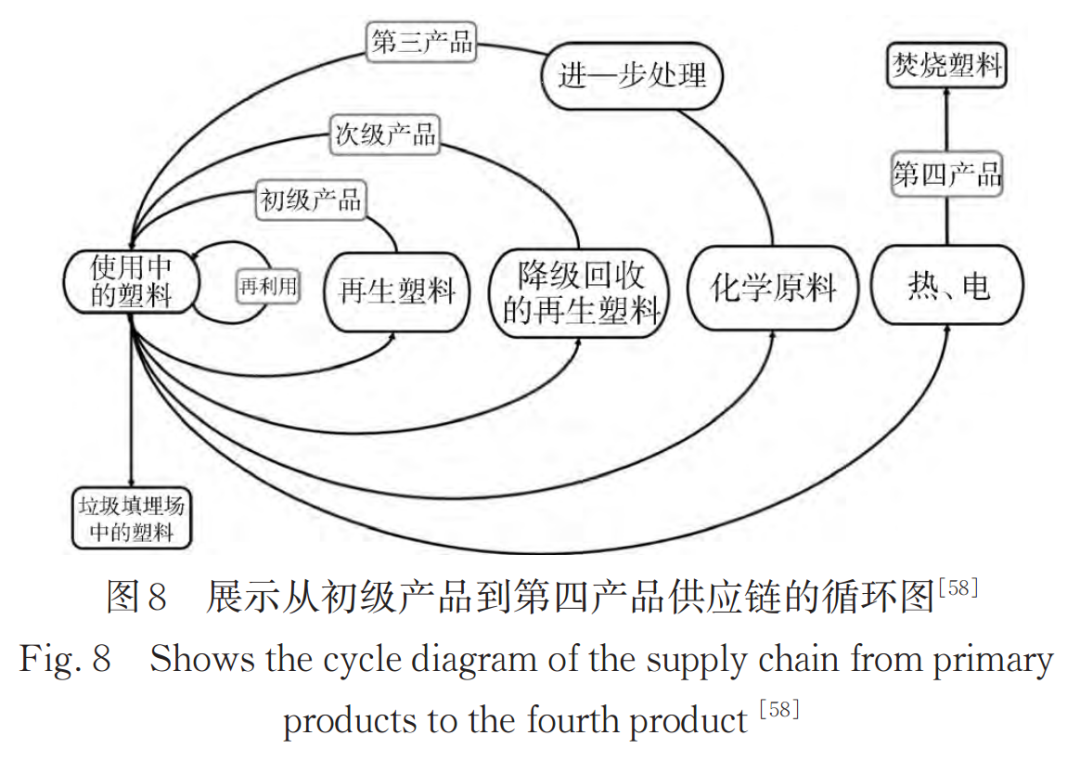

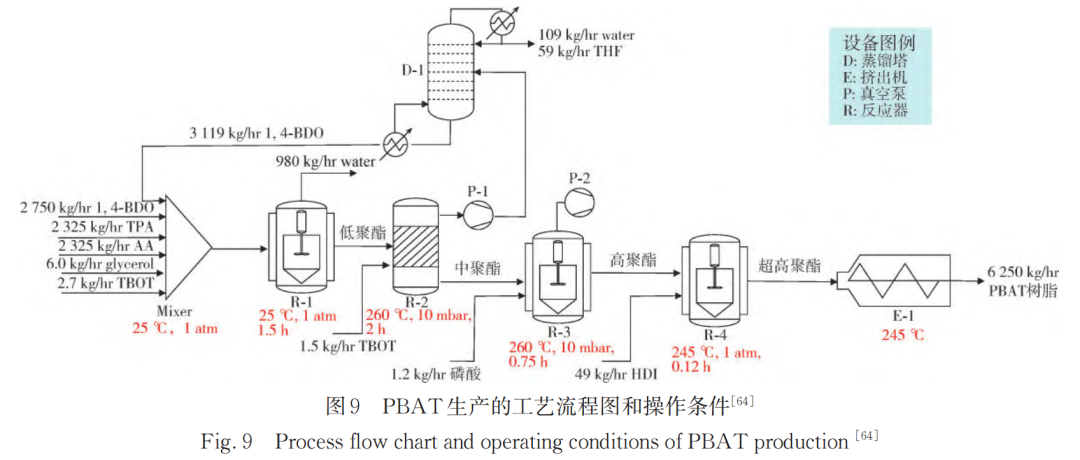

According to data from European Bioplastics, as of 2022, the global production capacity of bioplastics reached 2.22 million tons per year, with biodegradable plastics accounting for 51.5% (approximately 1.142 million tons per year), particularly prominent in the field of single-use products. It is expected that by 2027, this capacity will increase to 3.556 million tons per year. Single-use plastic products provide convenience in modern life, but their long degradation cycle and difficulty in recycling pose a serious ecological and environmental burden. Degradable plastics have become an important direction for solving this problem. Among them, PBAT has achieved preliminary substitution applications in the fields of packaging, agricultural films, and consumer goods due to its flexibility and processing performance similar to traditional plastics. However, its preparation process still relies on petrochemical raw materials. How to make PBAT more environmentally friendly throughout its entire "cradle-to-grave" lifecycle has become a current focus. Chemical recycling and life cycle assessment (LCA) are the two core technological routes driving the sustainable development of PBAT.

PBAT is an aliphatic-aromatic copolyester, which is soft, impact-resistant, and has good compatibility with other bio-based materials such as PLA and starch. It can achieve biodegradation under composting conditions, but the degradation rate varies in natural environments. Compared to traditional plastics, PBAT has significant advantages in the following aspects:

Mechanical properties close to those of low-density polyethylene (LDPE);

Suitable for conventional processing techniques such as film blowing, extrusion, and injection molding.

It can rapidly degrade in industrial composting environments.

For this reason, PBAT is considered one of the biodegradable plastics with the greatest industrialization potential.

2.1 Hydrolysis, Alcoholysis

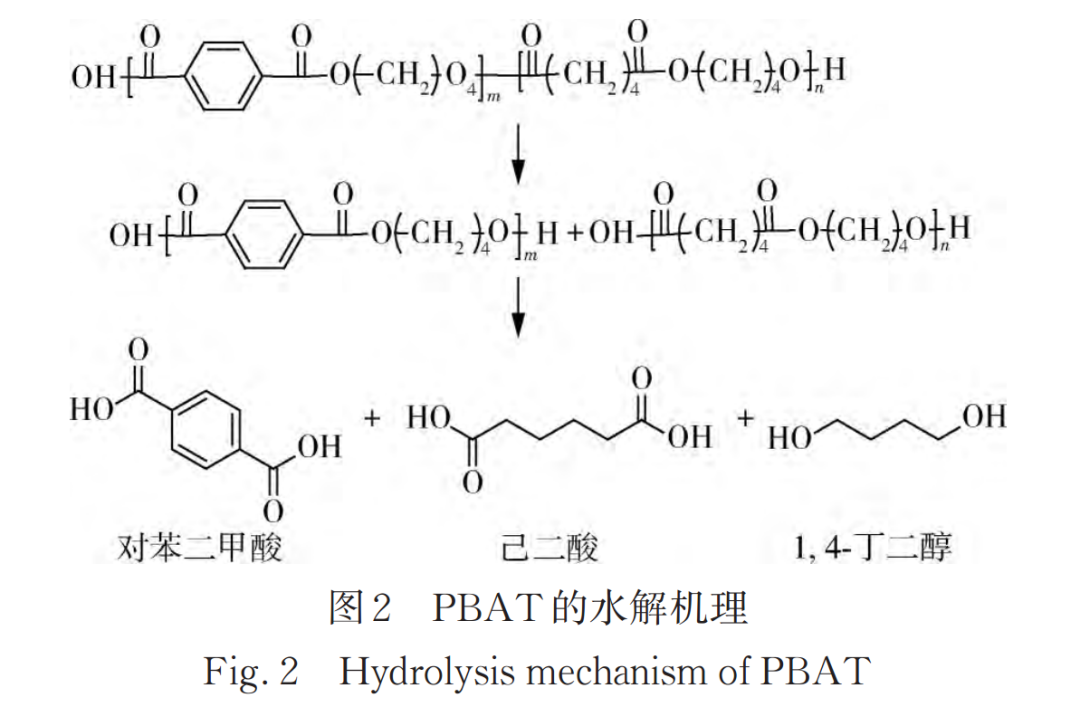

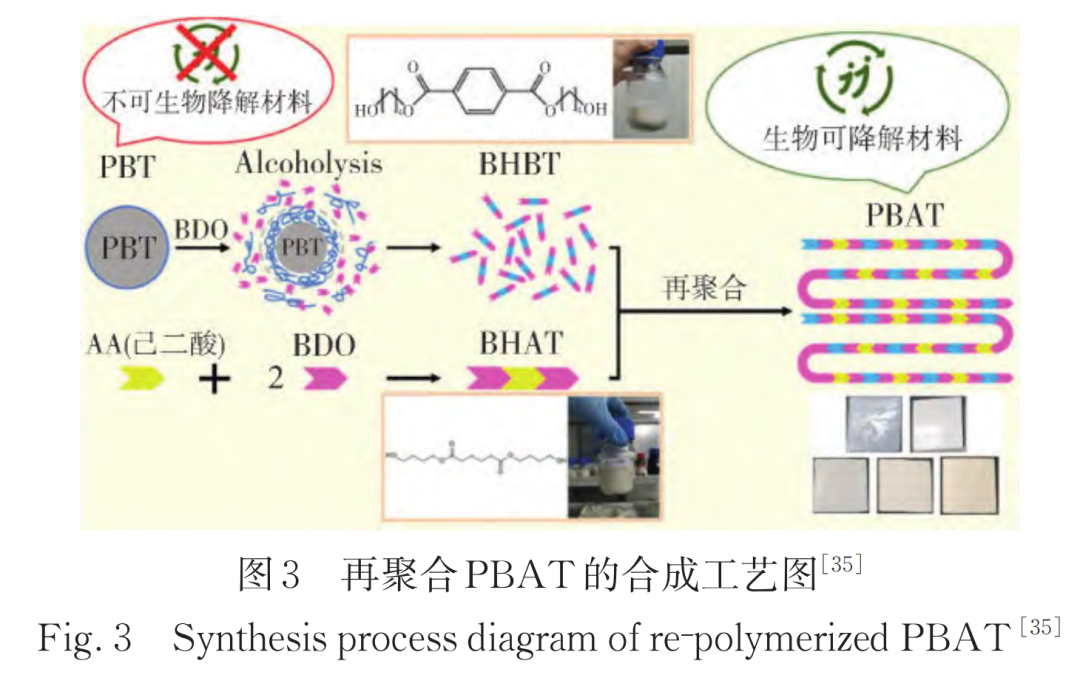

Hydrolytic recycling breaks the ester bonds in PBAT, decomposing it into monomers (TPA, AA, and BDO) and oligomers. Process conditions (such as pH, temperature, and crystallinity) significantly affect the reaction rate. Alcoholysis utilizes alcohols to depolymerize PBAT, and the products, after separation and purification by distillation or membrane separation, can be used for repolymerization. The key aspects of this technology are catalyst selection, control of reaction conditions, and the efficiency of product purification.

Key technologies in the alcoholysis recycling process of PBAT include: (1) catalyst selection; (2) control of reaction temperature and time; (3) amount of alcohol used; (4) product separation and purification; (5) equipment adaptability.

2.2 Thermal Chemical Recovery

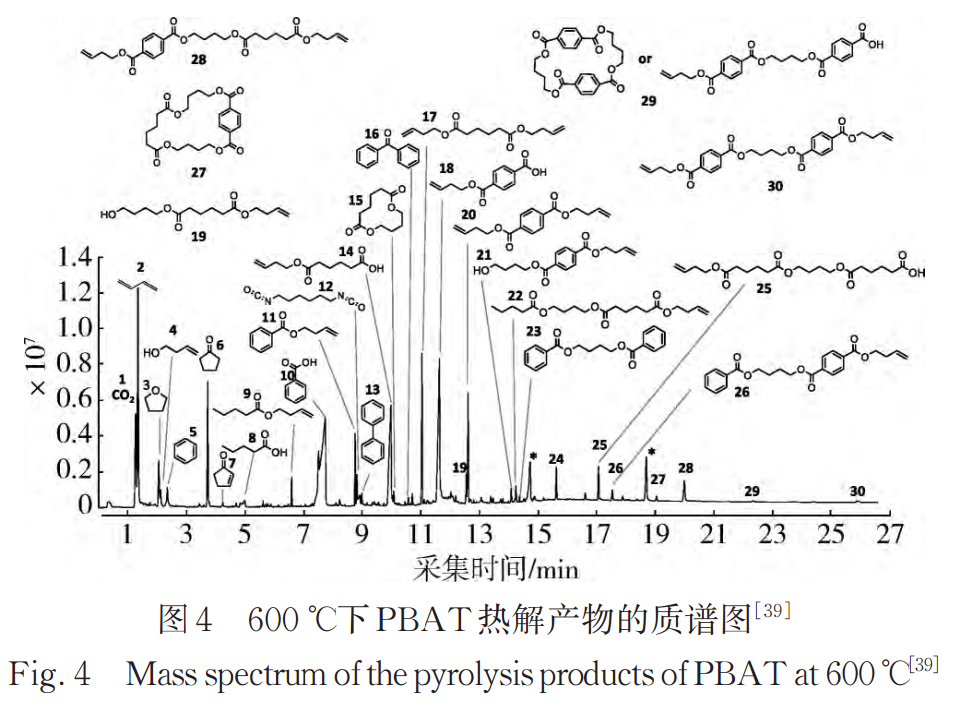

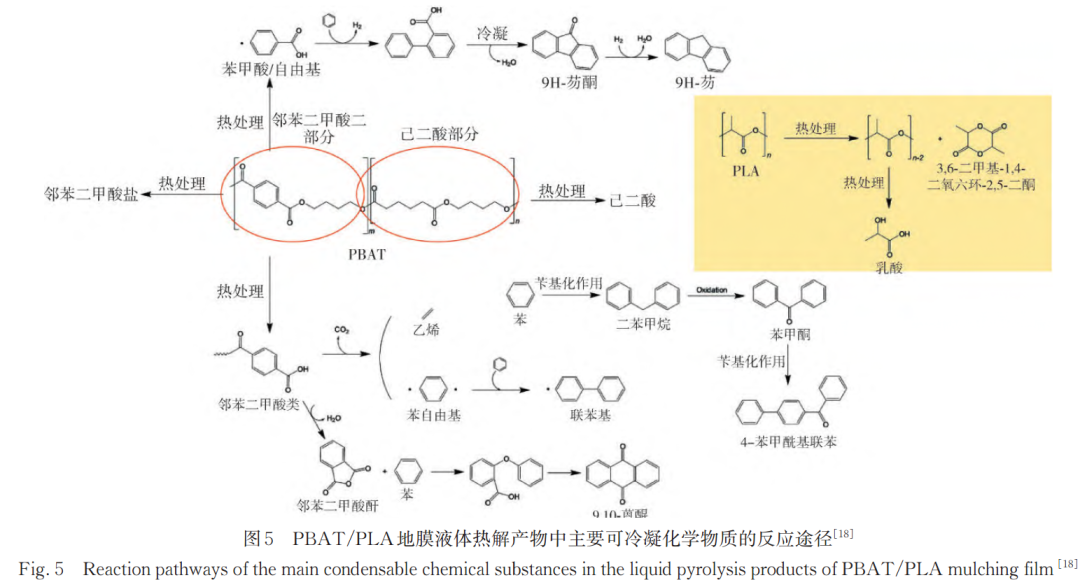

Pyrolysis is currently the most extensively studied method of chemical recycling. Under anaerobic or low-oxygen conditions, PBAT can be decomposed into monomers, oils, gases, and other secondary resources. Its advantages include a wide range of applicability and rapid reactions; however, it also has drawbacks such as high energy consumption and complex by-products. Therefore, it is necessary to optimize the reaction atmosphere and catalytic system to improve selectivity and recovery efficiency.

Key technologies in the pyrolysis recycling process include: (1) temperature control; (2) catalyst selection; (3) control of reaction atmosphere; (4) equipment design; (5) process optimization.

2.3 Biocatalytic Recycling

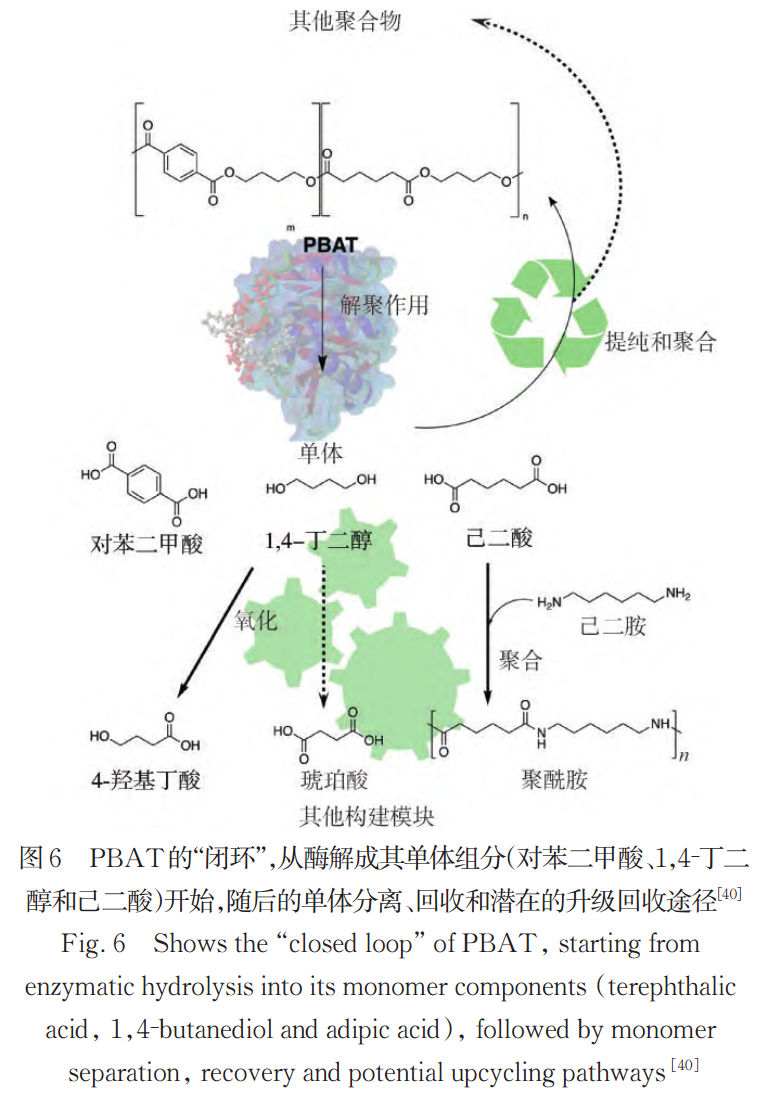

The enzymatic biocatalytic process for the recovery of PBAT monomers under mild conditions (atmospheric pressure, low temperature) offers advantages such as low environmental impact and high selectivity. However, the low efficiency of enzymatic hydrolysis, poor enzyme stability, and the high difficulty of product recovery and purification are key constraints to its industrial application.

The key technologies in the biocatalytic recycling process include: (1) enzyme screening and optimization; (2) control of reaction conditions; (3) microbial cultivation and utilization; (4) product separation and purification; (5) construction of the biocatalytic system.

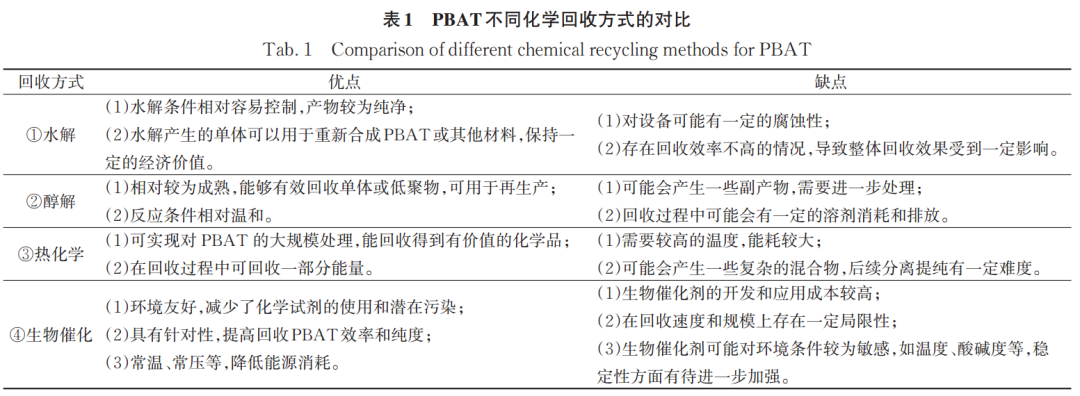

Table 1 summarizes the main advantages and disadvantages of various chemical recycling pathways for PBAT. Overall, PBAT chemical recycling technology is rapidly developing, with continuous investment from research institutions and companies driving the recycling processes towards efficiency, environmental friendliness, and innovation. Currently, pyrolysis is the most widely applied technology, capable of decomposing PBAT into reusable chemicals, serving as an important means for achieving resource circularity. Meanwhile, emerging chemical conversion processes are continuously appearing, such as catalytic conversion and solvent cracking, which can transform PBAT into new materials with different properties, further expanding its recycling pathways.

However, PBAT chemical recycling still faces many challenges. Technically, improving recycling efficiency, increasing product purity, reducing by-products, and avoiding secondary pollution remain key issues. Economically, high equipment and operating costs limit large-scale application. Overall, although positive progress has been made in this field, continuous technological innovation and process optimization are still needed to enhance recycling efficiency and product quality.

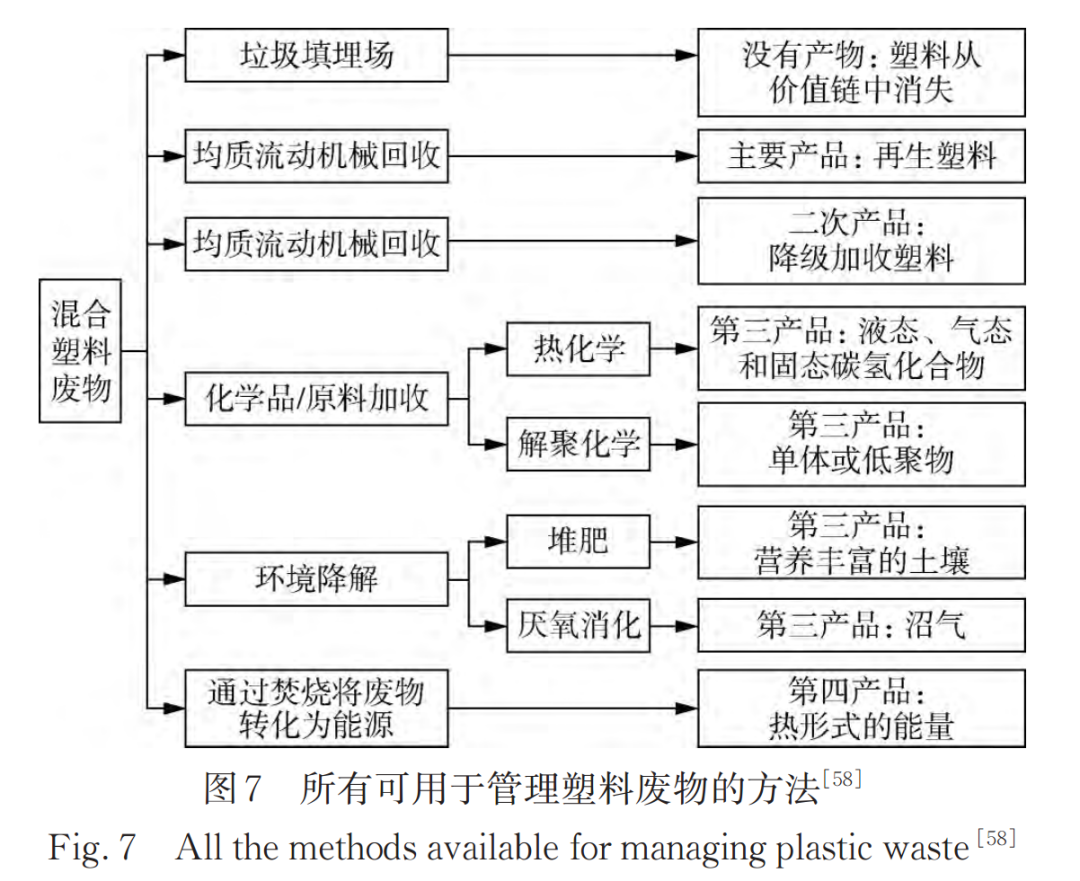

3.1 Application of LCA Method in Chemical Recycling

LCA is a key tool for assessing the environmental feasibility of chemical recycling technologies, typically based on the ISO 14040:2006 standard, which includes goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation of results. Chemical recycling LCA studies are often conducted through two approaches: direct comparison with mechanical recycling, or as a means of managing mixed plastics in combination with other methods. It is worth noting that chemical recycling is not a replacement for mechanical recycling, but rather a complementary pathway.

Currently, pyrolysis is widely used in LCA modeling due to the ease of data acquisition. However, this may cause bias against other technological pathways such as depolymerization and hydrocracking. To fairly assess the potential of various recycling pathways in the circular economy, there is an urgent need to establish a more comprehensive data system and standardized terminology.

3.2 Application of LCA Method in Chemical Recycling of PBAT

Studies have shown that bio-based raw materials can significantly reduce the overall carbon footprint of PBAT, but PBAT production remains a carbon-intensive process, primarily due to the high energy consumption of petroleum-based monomers. Several LCA studies have indicated that with appropriate policy support and technological innovation, chemical recycling can effectively reduce greenhouse gas emissions and resource loss in the PBAT waste treatment process. The recycling and reuse of bio-based BDO and TPA as substitutes for petrochemical monomers is a key direction for optimizing the environmental performance of the entire PBAT life cycle in the future.

How to achieve effective recycling and reuse of PBAT while maintaining material value and reducing environmental impact is a key issue currently faced. The challenges of PBAT recycling and reuse mainly include:

(1) Enzymatic hydrolysis efficiency issue: The current enzymatic hydrolysis technology is not ideal in degrading PBAT, and requires further optimization and improvement.

(2) Challenges in monomer recovery and purification: Current technologies have not yet been able to efficiently recover and purify monomers from PBAT degradation products, which limits the reuse of recovered materials.

(3) Repolymerization and Material Properties: The repolymerization capability of the recovered monomers and the properties of the resulting materials are key factors in assessing their reutilization value. To promote the recycling of PBAT, policy support is particularly important. The government can guide enterprises to increase R&D investment and promote process innovation and cost reduction by formulating incentive policies, establishing environmental regulations, and technical standards.

In addition, plastic production and recycling involve numerous chemicals, some of which have unclear environmental risks, adding complexity to the recycling process. During the plastic lifecycle, there may also be contamination from unintentional additives, leading to unknown components in recycled materials. Although some regions have restrictions on hazardous chemicals, international regulations on plastic additives remain inadequate.

Therefore, it is necessary to establish a global unified regulatory mechanism to promote the transparent reporting and monitoring of plastic-related chemicals, and to enhance the safety and sustainability of recycling materials like PBAT.

Overall, PBAT chemical recycling technology has made positive progress. Methods such as hydrolysis, alcoholysis, and pyrolysis can effectively recover monomers and valuable chemicals, achieving resource recycling, reducing environmental burdens, and possessing good economic and environmental potential.

Currently, there are still issues such as high costs, insufficient efficiency, and limited product purity, which affect its large-scale promotion. In the future, through the development of efficient catalysts, process optimization, and the introduction of intelligent control and other technological innovations, it is expected to improve recycling efficiency and economic viability. With the growing demand for recyclable biodegradable plastics in the market and strengthened policy support, the PBAT chemical recycling industry is expected to achieve faster development. Strengthening international cooperation and experience sharing will further promote its maturation.

In conclusion, despite some challenges faced by the chemical recycling technology of PBAT, its benefits for modern society and the future environment are evident. With continuous technological advancements, market drives, and policy support, we have reason to believe that in the near future, significant breakthroughs will be made in the chemical recycling of PBAT, contributing importantly to achieving a green and sustainable future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track