Changshu Automotive Interiors Expands to Spain with Smart Cockpit Layout, Spotlight on Key Applications of Plastic Materials

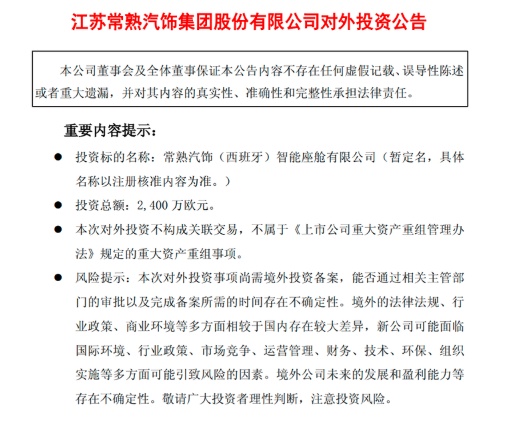

Special Plastic Vision, August 4 – Changshu Automotive Trim announced over the weekend that, based on strategic planning and the needs of overseas business development,To establish a wholly-owned subsidiary, "Changshu Automotive Trim (Spain) Intelligent Cockpit Co., Ltd.," with an investment of 24 million euros through its Luxembourg company in the Zaragoza region of Spain.The new company's business scope includes the production, sales, and trade of automotive smart cabins and related components. This investment aims to serve international clients, expand into overseas markets, and enhance competitiveness in the European market. However, the investment is still subject to overseas investment filing, and the new company faces various risks, with uncertainties in its future development.

Source: Company Announcement

As cars evolve into "mobile third living spaces," smart cockpits have become key, and automotive seats are also ushering in new development opportunities. The upstream supply chain includes key components such as seat slides and motors. Over 90% of the global seat market share is occupied by foreign enterprises, but with technological advancements, the rate of domestic production is continuously increasing. Under the trends of "intelligence, lightweight, personalization, and safety," local seat-related enterprises in China are facing opportunities, and the materials sector is also presenting four major development opportunities. As a vertical information service platform in the plastics industry, Zhuan Su Shi Jie has conducted an in-depth inventory on these developments.

Intelligentization: Optical Materials Lay the Foundation for Interaction

With the advancement of automotive intelligence, multimodal interaction has become a focal point, integrating multiple senses. In the future, automobiles will also support VR, AR, and holographic projection functions. This brings new possibilities for car seat design and requires a large amount of high-performance optical materials. For example, Yanfeng’s smart seats integrate touch screens, and the Tangqun Type X 2.0 intelligent seat system employs physiological detection technology. All these intelligent devices rely on high-performance optical materials. New types of optical film materials are constantly emerging, and high-performance polarizing films, among others, meet the demand for high-quality display effects in seat touch screens. At the same time, freeform surfaces, as key optical components, are gaining importance.Mainly using PC, COC, and glass materials, with optical PC materials currently being the most commonly used.。

Lightweight: The Opportunity for Lightweight Materials Has Arrived

Under the global "dual carbon" goals, new energy vehicles have become the development direction. Car seats account for a certain weight among the components, and their proportion may increase in the future. Covestro utilizes...Thermoplastic compositesCreating a lightweight seat back for GAC Group's electric concept car, reducing weight by up to 50% and being recyclable. Dow's POE-based synthetic leather solution enables the vehicle.The weight of the seat compared to PVC leatherReduce by 25-40%. The safety belt buckle housing of the Audi Q8 e-tron model is made from mixed automotive plastic waste, reflecting the concept of environmental protection.Lightweight metal materials can also achieve seat weight reduction.Lear's lightweight front seat frame adopts a lightweight design, weighing 10% less than the market average. The seat reduces weight through non-metal materials, primarily in components such as the backboard and surface, reflecting the concepts of lightweight design and carbon reduction for environmental protection.

Personalization: Textured materials are favored

As the cabin becomes an "intelligent third living space," personalization becomes a growth trend for seats. In the future, car seats and interiors will be more customized and personalized, with automotive personalized seats tending to use lighter, more breathable, and safer materials, while the use of leather seats will gradually decrease. Cars and homes will share many of the same materials.Johnson Controls Automotive uses feather-light carbon fiber, Renault creates custom fabric Bloko.Specialized Vision has discovered that Cupra, also a Spanish car manufacturer, has used Bcomp in its new bucket seats.Natural fiber compositesSolutions to replace seat backs made of carbon fiber and glass fiber. Meanwhile, seats will support more scenario experiences, and seat arrangements will become more flexible in the future. Current seat rail materials include cast iron and steel plates, and plastic has potential for development in the field of seat rails in the future. The main materials for seat recliners are currently PBT/ABS, and the introduction of new materials is expected to bring new changes.

Safety: Expansion of High-Performance Plastics Applications

Under the trends of intelligence, lightweight, and personalization, ensuring the safety of seats has become a challenge. In the future, seats will become part of passenger protection, linked with the vehicle's active safety systems, and some car seats have integrated multiple safety technologies. Currently,The main raw materials for airbags in the industry are PA66 and PET polyester.The addition of seat cushion airbags and headrest airbags provides more opportunities for related airbag plastics.

The establishment of an intelligent cockpit subsidiary by Changshu Automotive Trim in Spain is an important step in its overseas expansion. The development of intelligent cockpits has opened up a vast market space for plastic materials. From the optical materials required for intelligence to various plastic applications in terms of lightweight, personalization, and safety, there is significant potential for growth. However, relevant companies also need to pay attention to market changes and technological innovations to address various challenges and secure a position in the field of plastic materials for intelligent cockpits.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track