Cellulose and Polylactic Acid: Biomimetic Multifunctional Packaging Film Rapidly Degrades in Soil Environment

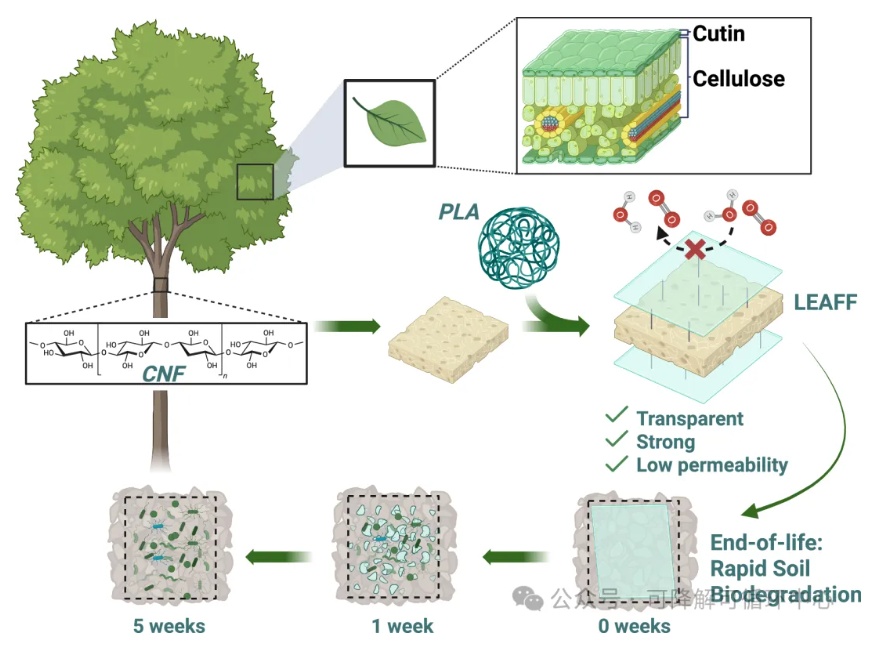

Bionic structure design enables PLA degradation at room temperature. The study draws inspiration from the multilayer structure of natural leaves to construct a "leaf-mimicking bionic film LEAFF": using cellulose nanofibers (CNF) as the framework, polylactic acid (PLA) as the coating layer, and cross-linking the interface with isocyanate (HMDI), combining strength and degradability, and can completely degrade in room temperature soil within 5 weeks.

2. Multifunctional synergy enables high-performance packaging films. LEAFF exhibits excellent mechanical properties: tensile strength (118.1±8.6 MPa), elastic modulus (10.6±1.2 GPa), gas barrier performance (oxygen permeability as low as 0.772 cm³/m²·d·atm), high transparency (approximately 49% light transmittance), water stability (retaining 77% of tensile strength after 36 hours of immersion), as well as printability and other multiple properties.

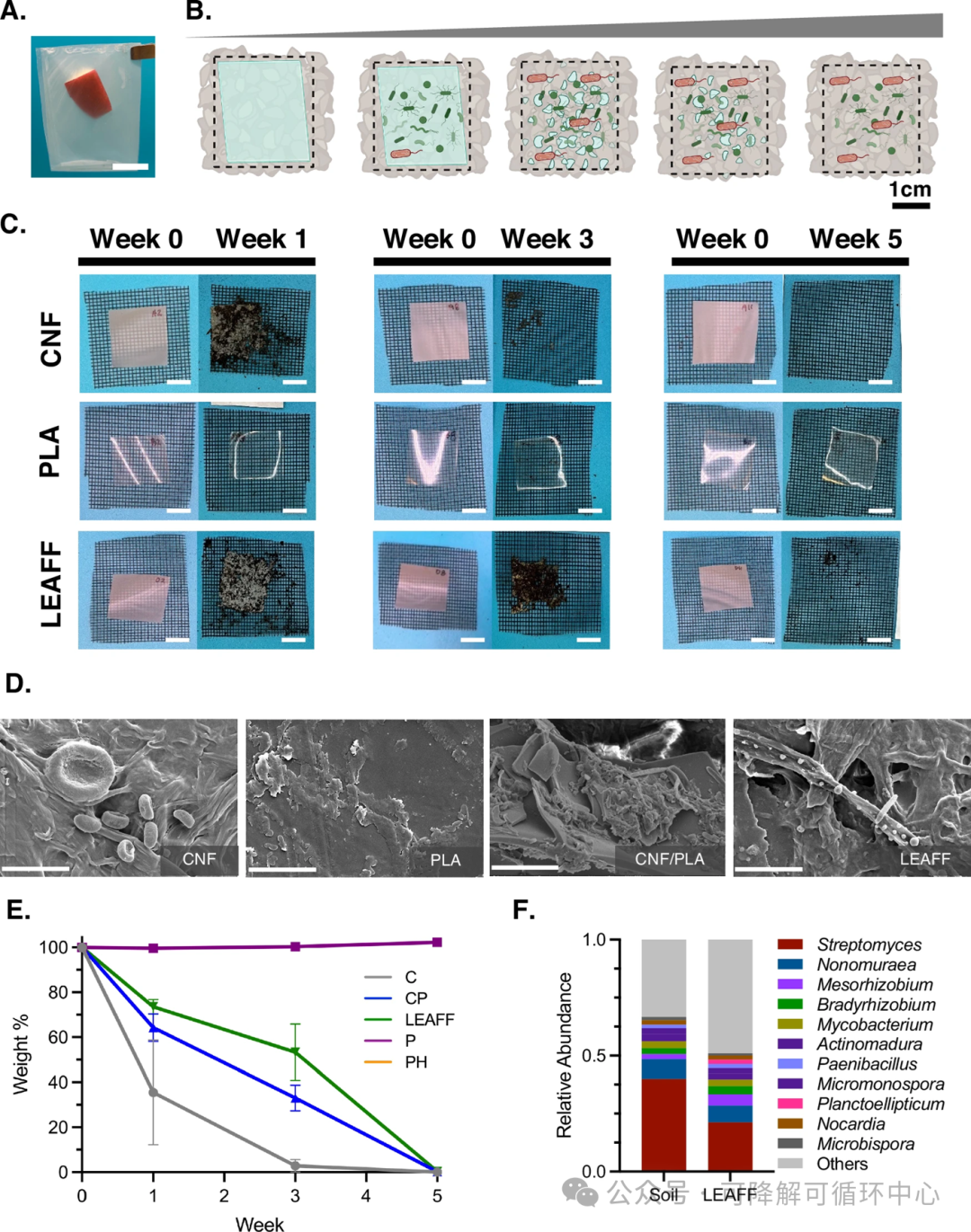

3. Regulation by the microbiome reveals degradation mechanisms. Soil microbiome analysis showed that a unique micro-ecological environment is formed during LEAFF degradation, enriching special microbial species such as Planctoellipticum variicoloris. It is speculated that these microbes assist in the breakdown of PLA chains via a phagocytosis-like mechanism. Meanwhile, CNF serves as an energy supply carrier, synergistically promoting the kinetics of PLA degradation.

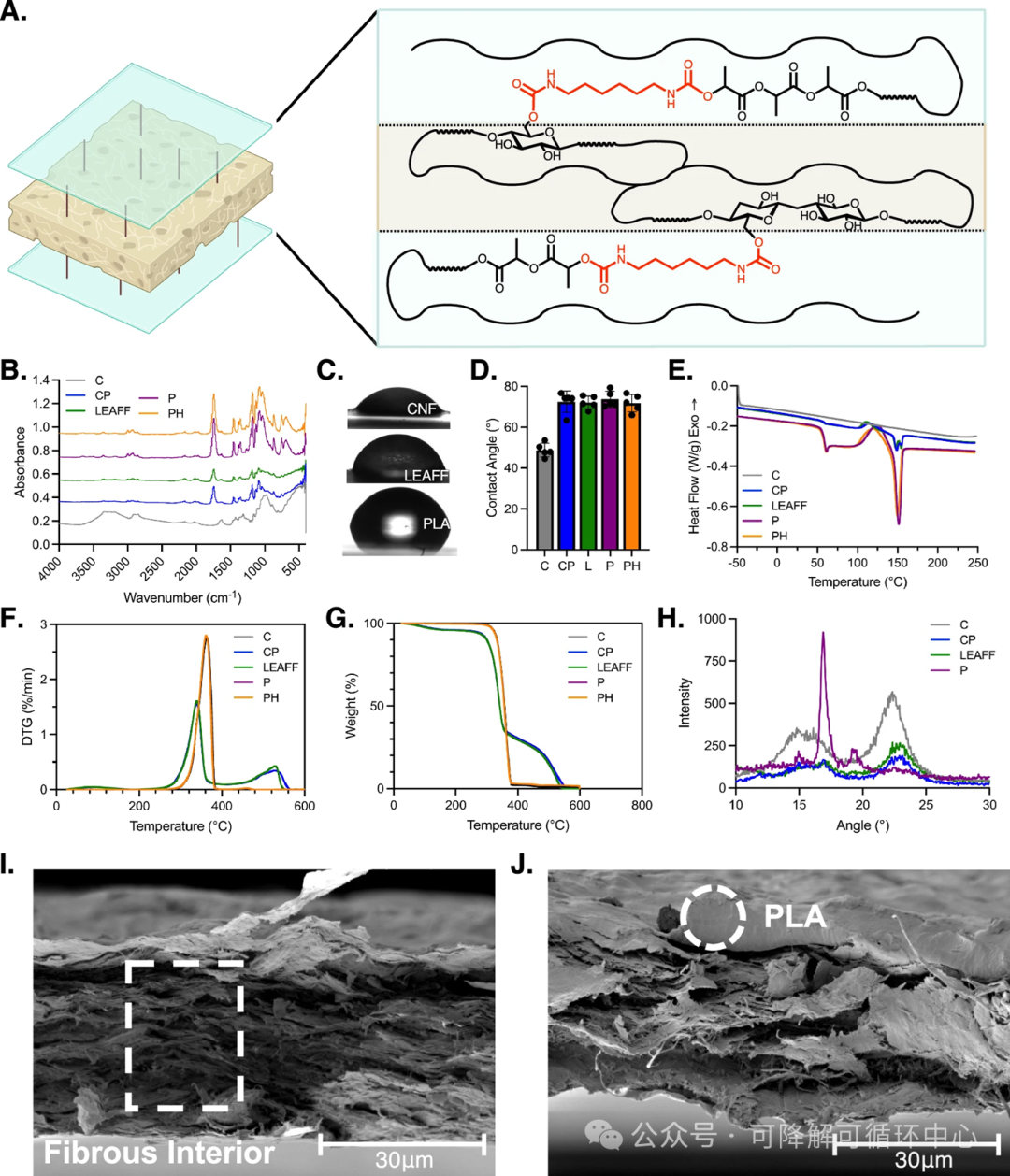

Figure 2. LEAFF microstructure and physical property characterization confirming PLA coating, interfacial crosslinking, and crystallization changes.

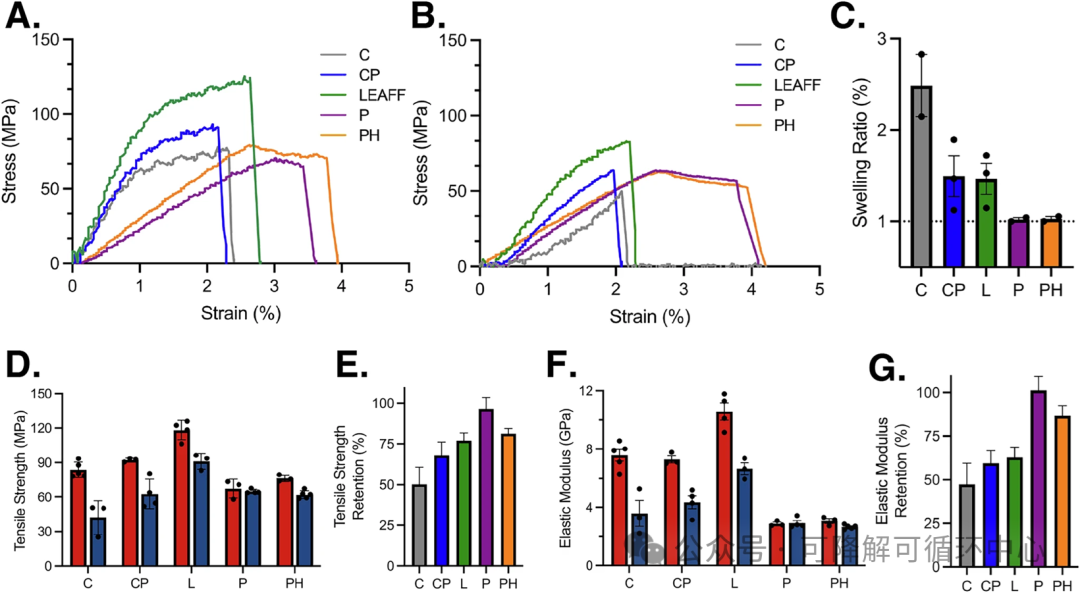

Figure 3. Mechanical performance tests of LEAFF in dry and wet states, demonstrating its superiority over traditional bioplastics and petrochemical film materials.

In the dry state, the tensile strength of LEAFF reaches 118.1 ± 8.6 MPa, and the elastic modulus reaches 10.6 ± 1.2 GPa, far exceeding pure CNF (83.7 ± 6.7 MPa, 7.6 ± 0.9 GPa), pure PLA (67.4 ± 8.3 MPa, 2.9 ± 0.2 GPa), and non-crosslinked CNF/PLA composite films (92.2 ± 1.6 MPa, 7.3 ± 0.4 GPa). After 36 hours of water immersion, LEAFF retains 77% of its tensile strength (91.1 ± 6.9 MPa) and 63% of its elastic modulus (6.7 ± 0.7 GPa), significantly higher than pure CNF (51%) and CNF/PLA (68%). Swelling tests show that the degree of swelling of LEAFF is close to that of pure PLA, indicating excellent water stability. This is closely related to its surface PLA coating, which is continuous and pore-free, effectively blocking water penetration.

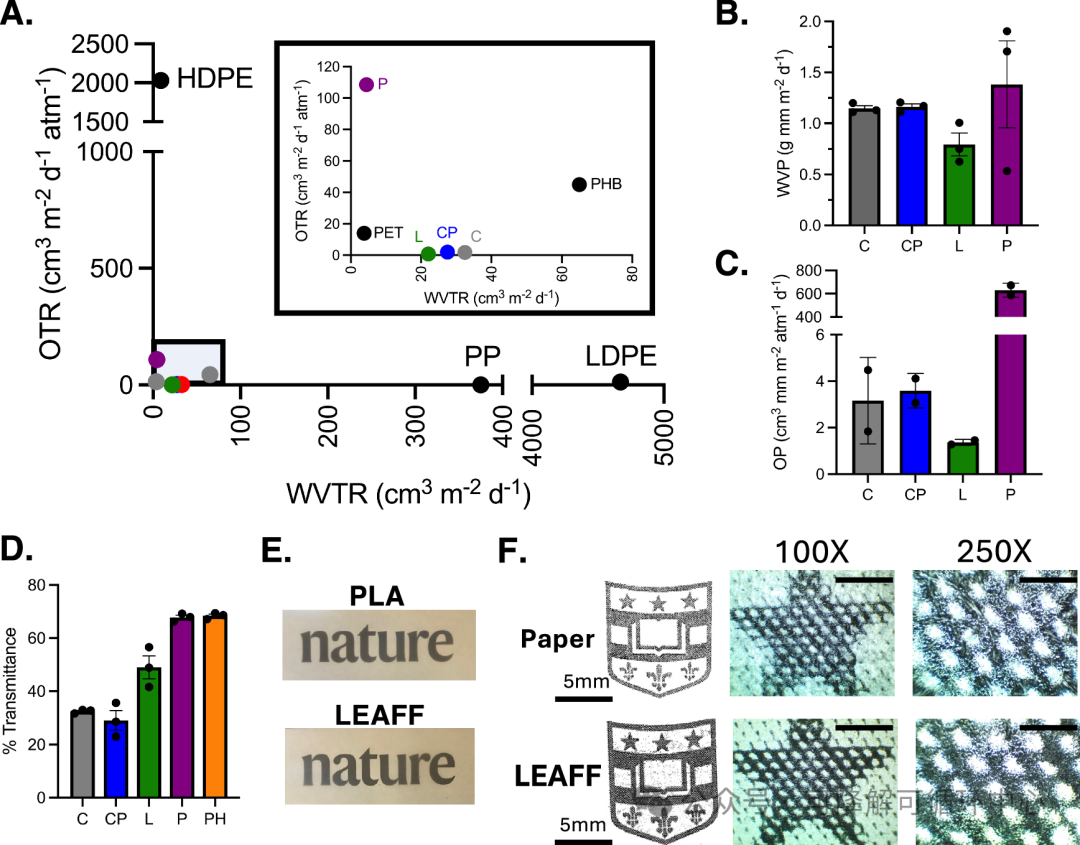

Figure 4. Multifunctional evaluation of LEAFF packaging, including oxygen/water vapor barrier properties, transparency, and printability.

Figure 4. Multifunctional evaluation of LEAFF packaging, including oxygen/water vapor barrier properties, transparency, and printability.

In terms of gas barrier properties, LEAFF exhibits a water vapor permeability (WVP) of 0.794 g·mm·m⁻²·d⁻¹, significantly lower than pure CNF (1.146), pure PLA (1.162), and non-crosslinked CNF/PLA (1.382); its oxygen transmission rate (OTR) is 0.772 cm³·m⁻²·day⁻¹·atm⁻¹, only 0.7% of pure PLA (108.5), demonstrating superior gas barrier performance compared to conventional plastics such as polyethylene and polypropylene. Regarding transparency, LEAFF has a light transmittance of approximately 49% at 600 nm, higher than CNF (33%) and CNF/PLA (29%), allowing clear visibility of text through it. Printability tests show that ink diffusion on its surface is less than that on traditional A4 paper, meeting packaging label requirements.

Figure 5. Degradation images of LEAFF in ambient temperature soil and analysis of microbiome changes reveal its rapid degradation mechanism.

Soil degradation experiments showed that LEAFF completely degraded within 5 weeks under conditions of 25°C and 40-60% humidity, while pure PLA exhibited no significant degradation. At 2 weeks, the remaining weight of LEAFF was about 40%, and SEM images revealed extensive microbial colonization on its surface, a phenomenon not observed on pure PLA. Microbial community analysis indicated that the Shannon diversity index in the LEAFF degradation environment increased from 6.5 (in soil) to 7.1, reflecting enhanced microbial diversity. Notably, the abundance of Planctoellipticum variicoloris—a Planctomycete bacterium capable of macromolecule uptake—rose significantly, suggesting that it may accelerate the degradation process by promoting PLA hydrolysis.

Our hypothesis is that the challenges of PLA biodegradation under environmental conditions are twofold: firstly, the chemical limitation of energy balance, and secondly, the physical limitation caused by the crystalline structure of PLA. The degradation of PLA involves an initial energy input for ester bond hydrolysis, followed by the release of low-energy lactide monomers that are converted into pyruvic acid and then funneled into central metabolism. Therefore, we hypothesize that the co-localization of high-energy cellulose provides energy for this energy-deficient microbial metabolic process, which is supported by the observation that soil microbial communities proliferate on LEAFF films but not on pure PLA films. Additionally, we engineered the films to enhance the contact between cells and secreted hydrolytic enzymes with the PLA polymer chains. Furthermore, the internal structure of CNF fibers allows soil microbes to grow and aggregate near the PLA material, further enhancing its biodegradability compared to pure PLA.

This work proposes a biomimetic hierarchical structure design to overcome the current bottleneck of “mutual exclusivity between high strength and biodegradability” in bioplastics. Inspired by the structure of plant leaves, CNF cores and PLA coatings are crosslinked via HMDI to achieve synergistic interfacial effects: on the one hand, the tensile strength and elastic modulus surpass those of conventional plastics (such as polyethylene and polypropylene); on the other hand, PLA is endowed with ambient soil biodegradability, addressing the limitation of PLA’s requirement for industrial composting. Meanwhile, by regulating the crystalline structure and densification, the material simultaneously achieves high transparency, water stability, and excellent gas barrier properties, integrating the multifunctionality required for packaging materials. In addition, it is discovered for the first time that specific microorganisms (such as Planctoellipticum variicoloris) can promote degradation, revealing a mechanism by which enhanced microbial diversity accelerates degradation. This provides a new structure–property–degradability correlation approach for bioplastic design.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track