Causes And Solutions For Short Shot Phenomenon In Injection Molding

Short shot, also known as insufficient filling or short fill, refers to the phenomenon where the polymer fails to completely fill all corners of the mold cavity.

The causes of under-betting and relevant solutions are as follows:

1. Unreasonable selection of injection molding equipment

When selecting an injection molding machine, the maximum injection capacity of the machine should be greater than the weight of the product (including the part, runner, flash, etc.). To achieve better results, the total injection volume should be kept below 85% of the maximum injection capacity.

The flow performance of the aggregate is poor.

In this situation, an appropriate amount of additives should be added to the raw materials to improve the flow properties of the resin. At the same time, the proportion of recycled materials in the raw materials should be checked and appropriately reduced.

Alternatively, consider improving the mold's gating system by adjusting the position of the runner, enlarging the gate, runner, and gate size, and using a larger nozzle, thereby improving the stagnation defects of the mold's gating system.

3. The actual gating system is unreasonable.

A reasonable gating system takes into account the balance of gates and runners, ensuring that the cavity volume in each mold is proportional to the gate size, allowing the polymer to fill each cavity simultaneously. Additionally, the gate location should be chosen at the thick-walled area, and a balanced runner layout design can also be adopted.

For situations where the gate or runner is small, thin, and long, the pressure loss of the melt during flow is too great, hindering flow and easily causing underfilling. To address this, the cross-section of the runner and the area of the gate should be enlarged. If necessary, a multi-point gating method can be adopted.

4. Material temperature and mold temperature are too low.

Under normal circumstances, the melt temperature is approximately proportional to the filling length. A lower melt temperature will reduce the flowability of the melt, resulting in a shorter filling length. When it is confirmed that the melt temperature is low, the barrel heater should be checked for proper functioning, and efforts should be made to increase the barrel temperature.

If it is necessary to use low-temperature injection to prevent melt degradation, the temperature of the front section of the barrel can be appropriately increased, or the injection speed can be accelerated to reduce the cooling time of the polymer. However, it should be noted that excessive injection speed may cause melt fracture, resulting in wrinkle defects.

Lower mold temperatures can cause the molten polymer to cool prematurely, preventing it from filling the entire cavity. To address this situation, the mold should be heated to a temperature that meets process requirements, and at the initial stage of injection molding, the flow rate of the cooling medium should be reduced. If the mold temperature remains consistently low, the design of the cooling system should be changed.

5. Low injection nozzle temperature

During the injection process, the nozzle comes into direct contact with the mold. Since the mold temperature is generally lower than the nozzle temperature and the temperature difference is quite large, frequent contact between the two causes the nozzle temperature to drop, resulting in the condensation of the melt at the nozzle (also known as "dry tip").

To prevent the cold material from solidifying immediately after entering the cavity and blocking the subsequent hot melt material from filling the cavity, consider adding a cold slug well in the runner. Additionally, ensure that the nozzle is separated from the mold during mold opening to reduce the influence of mold temperature on the nozzle temperature.

6. Injection pressure and insufficient holding pressure

The injection pressure is approximately proportional to the filling length. Low injection pressure can result in a short filling length, leading to underfilling.

In this situation, the injection pressure can be increased by slowing down the forward speed of the injection ram and appropriately extending the injection time. When the injection pressure cannot be further increased, the melt temperature can also be moderately raised (without causing decomposition of the melt) to reduce the melt viscosity, thereby improving the melt flow properties as a remedy.

In addition, if the holding pressure time is too short, short shots may occur. Therefore, selecting an appropriate holding pressure time (generally controlled between 30 to 120 seconds, which can be appropriately increased for thick-walled products) can prevent short shots. At the same time, it should also be noted that excessively long holding pressure times may cause difficulties in the automatic ejection of the products.

7. Unreasonable product structure design

When the overall dimensions of a product are disproportionate (for example, the thickness is not in proportion to the length), or when the product has a complex shape with a large molding area, the melt can easily encounter flow resistance in the thin-walled sections of the plastic part, resulting in insufficient filling. Therefore, when designing the shape and structure of a plastic part, attention should be paid to the relationship between the part’s thickness and the maximum flow length of the melt during mold filling.

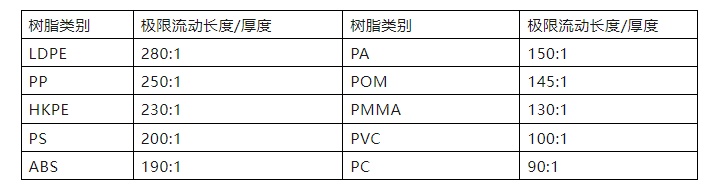

The ratio of the maximum flow length of the melt to the thickness of the part during the mold filling process:

In injection molding, the thickness of plastic parts is generally 1 to 3 mm, while for large plastic parts it is 3 to 6 mm. Typically, a part thickness exceeding 8 mm or less than 0.5 mm is unfavorable for injection molding.

In addition, when molding complex structural plastic parts, it is necessary to adopt appropriate process measures, such as properly adjusting the runner layout, reasonably determining the gate location, increasing the injection speed, raising the mold temperature and material temperature, and selecting resins with better flow properties.

8. Poor exhaust

Poor exhaust will cause a large amount of gas to remain in the mold cavity, which is then compressed by the flowing material, generating a high pressure. When this pressure exceeds the injection pressure, it will hinder the filling of the melt into the mold, resulting in short shots.

For this phenomenon, check whether the cold slug well is set up or if its position is reasonable. For deep cavity molds, venting grooves or vent holes should be set at the location where short shots occur. Venting grooves can be made on the parting surface of the mold, with a depth generally between 0.02 to 0.04mm and a width of 5 to 10mm. Vent holes should be set at the final fill area of the cavity. For volatile or high-moisture polymers, the volatile components should be removed or dried before injection molding.

By changing the process parameters of the mold system, the issue of poor venting can also be improved. For example, measures such as increasing the mold temperature, reducing the injection speed, decreasing the clamping force, and increasing the mold clearance can be taken.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track