CATL and Cathay Biotech Announce 2.5 Million Unit Mega Project!

Once again, nylon is in the spotlight. However, unlike the special nylon that Sinopec, Kingfa Sci & Tech, and Shenma Group collectively ventured into a few days ago, this time it is bio-based nylon composite materials. These materials have applications not only in batteries but also in photovoltaics and construction. The industry has been watching the commercialization of bio-based new materials, and finally, there has been a new breakthrough.

[DT New Materials] has learned that on August 11, the Ningde Times-Kesai (Hefei) bio-based battery case manufacturing base project, undertaken by Anhui Kaisa Times Composite Materials Co., Ltd. (hereinafter referred to as "Anhui Kaisa Times"), was announced.

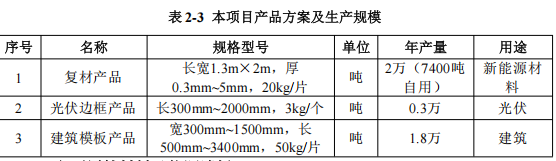

The total investment is 500 million yuan, with plans to build 18 battery case production lines and supporting facilities. The project will use long glass fiber and short glass fiber bio-based nylon 56 composite materials. Once at full capacity, it will be able to produce 2.5 million sets of bio-based battery cases annually. The product thickness is 1.0mm for the main surface and 3mm for the surrounding flange.

According to available information, Anhui KaiCai Times was jointly established on February 12, 2025, by Cathay Biotech, Puquan Capital (the industrial investment platform under CATL), and Carlai Composites. The company, with legal representative LIU XIUCAI, integrates bio-based polyamide (PA56) synthesis technology with CTP3.0 battery integration processes, and is engaged in the research and development, production, and sales of bio-based composite material products applied in battery casings, energy storage enclosures, automotive parts, and other transportation sectors.

The raw materials for this battery casing project rely on the annual production of 41,000 tons of bio-based composite materials project announced by China National Chemical Corporation's Kaisai Biological Materials (Hefei) Co., Ltd. in June this year.

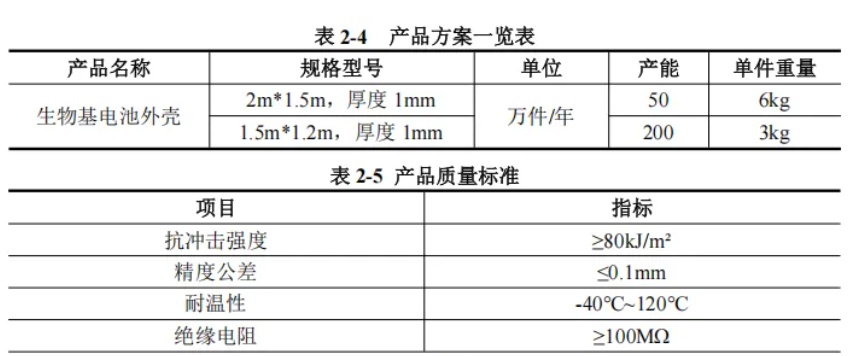

The project will involve an investment of 468.5 million RMB, with a construction period from April 2025 to December 2026. Using bio-based nylon 56 and glass fiber yarn as the main raw materials, the facility will produce 20,000 tons/year (of which 7,400 tons are for internal use) of composite products (with dimensions of 1.3m × 2m and thicknesses ranging from 0.3mm to 5mm), 3,000 tons/year of photovoltaic frame products (lengths ranging from 300mm to 2,000mm), and 18,000 tons/year of construction formwork products (widths ranging from 300mm to 1,500mm and lengths from 500mm to 3,400mm).

Among the photovoltaic, construction, and transportation material products, there is also a major collaboration behind the scenes. In June last year, Cathay Biotech and Fuyang Transportation Energy Investment Co., Ltd. announced in Shanghai the establishment of a strategic partnership, focusing on the industrial application of bio-based polyamide composite materials.

Moreover, Cathay Biotech also signed an agreement in Shanghai last January with South Korea's 3P.COM company to establish a joint venture, dedicated to the development of applications for thermoplastic bio-based polyamide composites, including hydrogen storage and transportation, urban air mobility, and wind turbine blades.

According to the plan, Cathay Biotech will complete the construction of a bio-based polyamide modification and Bio-PPA CFRT factory in Hefei by 2025. The joint venture company, established with leading downstream industries for Bio-PPA CFRT, is also currently under construction and operation.

As of the end of 2024, Cathay Biotech's bio-based nylon series products are still operating at a loss, heavily relying on the profitability of long-chain dibasic acids. However, the company has completed the entire industry chain from upstream monomers to resins to composite materials, and has initiated application layouts for its composites in various markets, including batteries, photovoltaics, construction, hydrogen storage tanks, wind turbine blades, high-speed rail flame-retardant flooring, and high-transparency wave materials for 5G base stations. The project supplying battery casings for CATL, which is currently in the spotlight, may become the best proof of the quality of the company’s products and is expected to bring more confidence to the bio-based materials industry.

When discussing the current "success" of Cathay Biotech, it can be said that the major investment of 6.6 billion yuan by China Merchants Group, along with the provision of direct user resources and a direct procurement agreement for 290,000 tons of bio-based polyamide over three years (with a procurement volume of 200,000 tons in 2025), has played a crucial role. This is also a development model worth emulating for many new materials companies.

Of course, there is also the inherent charm of bio-based nylon composites.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track