Car Hidden Door Handles to Exit! National Action to Rectify, Plastic Door Handles to Bring Big Changes

Specialized VisionOn September 25th, it was reported that,The Equipment Industry Division of the Ministry of Industry and Information Technology has publicly solicited opinions on the mandatory national standard for "Safety Technical Requirements for Automotive Door Handles" and three amendments to mandatory national standards, which explicitly prohibit the use of...The "fully concealed" exterior door handles have sparked widespread attention and discussion. This seemingly ordinary component of the automobile, the door handle, has once again become a focal point in the industry.

Image source: Urban Express

Hidden Door Handles: From Glamour to Ban

In recent years, the new energy vehicle market has been booming, and hidden door handles have become a design element adopted by many car manufacturers. The main reasons for their popularity are twofold: firstly, they can reduce the impact of wind resistance on the car to a certain extent, thereby lowering energy consumption. According to statistics, a single hidden door handle can reduce approximatelyA drag coefficient of 0.003 Cd, with passenger cars typically having four door handles, can reduce the total by approximately 0.012 Cd; secondly, it enhances the appearance, giving a sense of technology and futurism, aligning with the innovative and fashionable positioning pursued by new energy vehicles.

However, while hidden door handles offer these advantages, they also expose several issues. In electric vehicle collision accidents, door handles often fail to pop open, greatly increasing the difficulty of rescue. Rescuers are unable to quickly open the car door, which may delay critical rescue time and pose a serious threat to the safety of the passengers inside. Additionally, in cold regions such as the Northeast, during heavy snow, hidden door handles may become frozen shut, occasionally making it difficult to open the door. Sometimes, additional actions like heating are needed to open the door, causing significant inconvenience to the car owners.

In order to achieve a bit of so-called aesthetics and a slight reduction in wind resistance, consumers have to endure numerous usability issues, which is truly not worth the cost. The new technical requirements clearly state that each car door (excluding the tailgate) must be equipped with an external door handle that has a mechanical release function, ensuring that in the event of an irreversible restraint device deployment or a thermal incident with the power battery while the locking mechanism is engaged, the non-collision side door can be opened without the use of tools via the external door handle. This regulation is undoubtedly a relief, reflecting consumers' long-standing dissatisfaction with hidden door handles.

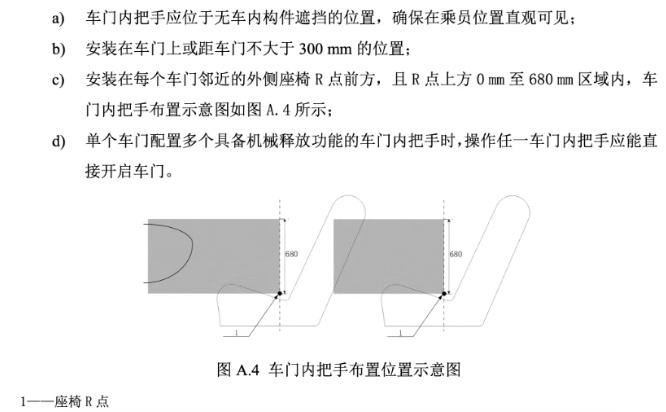

Source of the image: Draft of the new national standard for public consultation.

Currently, the hidden door handles on the market can generally be divided into rotary type and electrically pop-out push type, and the opening methods designed by different car manufacturers vary. For example, Changan Deep Blue.After unlocking, the S7 opens automatically with a rotating mechanism, while Tesla requires you to press the back, lift the door handle, and then pull to open the door. This diversity in design seems to reflect automotive companies' innovation. However, it actually causes inconvenience to consumers, increasing the difficulty of use. In emergency situations, unfamiliarity with the operation might prevent timely door opening. Such designs that affect usage safety should indeed be eliminated. Automotive companies should reflect, prioritizing actual user experience and safety over creating demand.

Specialized Vision Revealed:Car door handle plastic material

Automotive door handles produced domestically are divided into two types based on material forming processes: alloy die casting and plastic injection molding. Among them, plastic injection molded automotive interior door handles have a wide variety of materials, each with its own characteristics and applicable scenarios.

ABS resin:ABS resin was applied relatively early in the field of interior car door handles. However, due to its poor mechanical properties, ABS resin is now rarely used in door handles. ABS resin for interior car door handles is divided into general-purpose and heat-resistant types. General-purpose ABS has good electroplating performance and can be used in scenarios where electroplating effects are required but mechanical performance requirements are not high. Heat-resistant ABS resin generally has a heat distortion temperature of 90 - 105°C and possesses good rigidity, toughness, and fluidity. It once met the usage requirements for door handles to a certain extent, but with technological advancements, it has gradually been replaced by other materials.

PC:PC is an engineering plastic with excellent mechanical properties, which makes it less prone to deformation and damage when subjected to certain external forces, ensuring the longevity of door handles. However, the electroplating performance of PC is not very good, which imposes certain limitations during use. In designs of door handles that require a high demand for metallic appearance and need to achieve this through electroplating, PC may not meet the requirements. However, there is still potential for application in door handles with lower aesthetic demands or those using other surface treatment methods.

PC/ABS:PC/ABS resin is the fastest-growing and most widely used material for interior car door handles. It is an alloy of PC and ABS, combining the high strength of PC with the easy electroplating properties of ABS. It is mainly divided into two types: electroplating and spraying. Compared to sprayed PC/ABS resin, electroplated PC/ABS resin has a more metallic appearance, making it look more upscale and able to meet consumers' aesthetic requirements for car interiors. Therefore, it is widely used in the mid-to-high-end car door handle market.

PC/ABS door handle, image source: Mattel on plastic modification.

PC/PBT:PC/PBT is a blended material of PC and PBT, which retains the chemical resistance and ease of molding characteristics of crystalline material PBT, while also possessing the toughness and dimensional stability of non-crystalline material PC. However, the application of PC/PBT in interior car door handles is not very common domestically at present. But with the increasing performance requirements of materials in the automotive industry, its potential application value is expected to be further explored.

PA:PA has excellent mechanical properties, but its electroplating performance and water absorption are two major challenges for its application in car interior door handles. In foreign countries, such as Germany, there is a high requirement for tensile strength, and electroplated PA is widely used in German cars. PA used for car interior door handles is generally divided into two types: spray-painted PA and electroplated PA. The composition of electroplated PA is generally PA + 20% mineral, with minerals added to improve its performance to meet the requirements of door handle usage.

This ban will be implemented.Small and medium-sized component enterprises welcome favorable policies.

The recent government crackdown on automobile door handles is good news for small and medium-sized automotive parts companies. Take Alpha Edward Vehicle Components Co., Ltd. as an example. This company supplies door handles to enterprises like Xiaomi. Under the new technical requirements, the market for hidden door handles is gradually shrinking, while the demand for traditional or new door handles that meet safety standards and have mechanical release functions will increase. Small and medium-sized parts companies can leverage their flexibility and innovation capabilities to quickly adjust product strategies, increase investment in the research and production of door handles that meet the new standards, and seize market share.

At the same time, this will also encourage the entire auto parts industry to pay more attention to product quality and safety performance, promoting technological innovation and upgrades within the industry. Companies need to continuously improve in areas such as material selection, design optimization, and production processes to enhance the reliability, durability, and safety of door handles, meeting the needs of the market and consumers.

The adjustment of safety technical requirements for car door handles by the government is a strong safeguard for consumer rights and a guide for the healthy development of the automotive industry. Saying goodbye to hidden door handles not only makes travel safer and more convenient for consumers but also brings new development opportunities for automotive parts companies, promoting the entire industry towards a more standardized and high-quality direction.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track