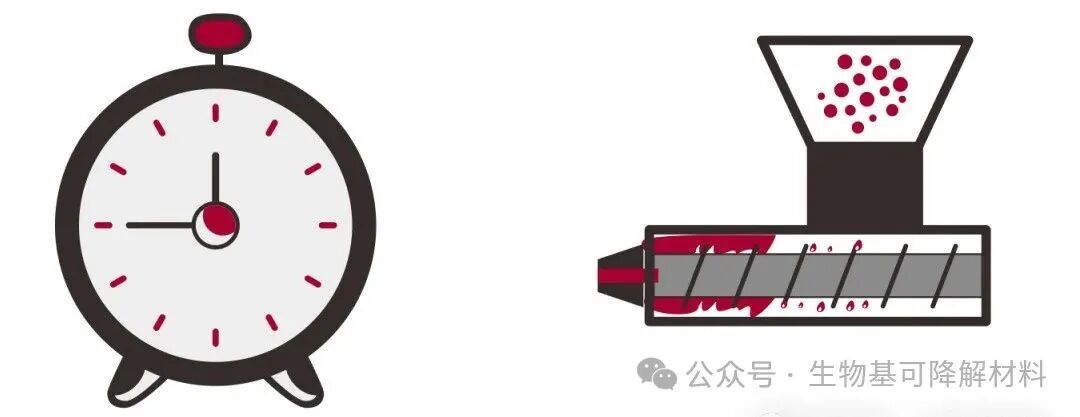

Calculation and Application of Residence Time of Polymer Materials in Screw Extruders

In polymer material processing, especially in the extrusion molding of degradable materials, the residence time of the material in the screw extruder is a critical parameter.Also known as residence time(HUT) refers to the time plastic pellets take from entering the extruder to flowing out of the die, which is directly related to whether the material will undergo thermal degradation due to prolonged heating. Today, we will discuss how to scientifically calculate this time and its importance.

Calculation formula of residence time

In actual production, the commonly used residence time (T) calculation formula is based on the volumetric flow rate of the material and the filled volume of the material inside the extruder, as follows:

T =V/Q

Among them:

T represents the dwell time (unit: minutes).

V is the effective filling volume of the material inside the extruder (unit: liters), which can typically be estimated based on the screw diameter, effective length, and filling rate (for simplified calculations, it can be approximated as the effective volume of the screw, i.e., V = Πd).2L/4000, where d is the screw diameter (cm) and L is the effective length of the screw (cm).

It should be noted that:

In the formula, use "V = Πd".2L/4000" calculates the total volume of the barrel (i.e., the volume of the cylindrical space inside the barrel). However, in reality, the screw itself occupies a portion of the space inside the barrel, and the material can only fill the threads between the screw and the barrel. Therefore, this formula is essentially a simplified estimation for the following reason:

For example:

Taking the extrusion processing of PBAT material as an example:

If the filling rate is 60%, the effective filling volume of the material V = 8.7 * 60% ≈ 5.2 liters.

Under this process, the actual residence time of the material is approximately 1.3 minutes, which is much lower than the thermal degradation critical time of PBAT (usually 5-8 minutes), ensuring process safety.

The role of scientifically managing dwell time.

Avoid thermal degradation: For polymers such as bio-based biodegradable materials that are sensitive to heat, prolonged residence time can lead to chain scission and performance degradation. Scientific management can effectively reduce these issues.

Ensuring product stability: Stable residence time ensures uniform heating and shearing of materials, reducing fluctuations in product performance (such as mechanical properties, appearance, etc.).

Improve production efficiency: By optimizing residence time, it is possible to reasonably increase processing speed without causing degradation, balancing quality and capacity.

Reducing production costs: minimize waste caused by degradation, reduce rework rate, and indirectly enhance production efficiency.

By mastering the calculation method of residence time, practitioners can more accurately adjust parameters such as screw speed and feed rate, providing a scientific basis for the extrusion processing of polymer materials. This is especially crucial for ensuring product quality in the case of heat-sensitive bio-based degradable materials.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track