Building a Foundation for Enterprise Development Through Technology Inheritance | Fu Chun Shin Group Wins Two Awards at the 2025 Plastics Industry Conference and Brand Ceremony

The 2025 (4th) Plastic Industry Conference and Brand Festival recently concluded successfully in Foshan.

At this summit, over 1,000 participants, including leaders from more than 350 leading enterprises nationwide, nearly 50 industry association heads, and experts and scholars, gathered together. More than 70 brand enterprises showcased their innovative strengths on site. The attendees engaged in in-depth exchanges on key topics such as transformation paths under the goal of high-quality development, practical exploration of intelligent manufacturing, brand building, and business strategies. This helped to consolidate industry consensus and pointed out the direction for the high-quality development of the plastics industry.

At this industry grand event's "Plastics Industry Oscars" award ceremony, Fuqiangxin Group, with its profound brand heritage and forward-looking innovative strength, won two prestigious honors: the 2025 "Outstanding Influential Injection Molding Machine Brand" and the "Plastics Industry Innovative Product Award."

This is not only an authoritative recognition of FCS's outstanding achievements over the past year in technological breakthroughs, high-end equipment iteration and R&D, global market expansion, and customer service system development, but also highlights the industry's high expectations for its leadership in driving technological innovation in the injection molding machine sector and promoting high-quality development in the plastics industry. It injects strong momentum into the advancement of Chinese plastic machinery brands in the global industrial chain.

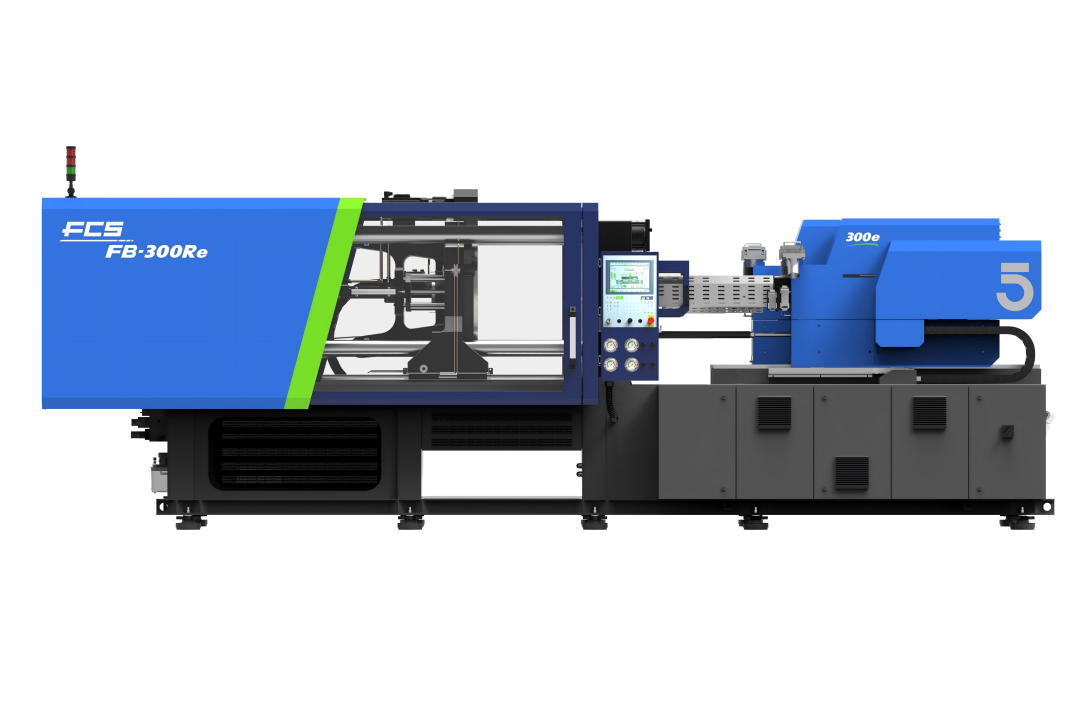

FCS FB-R Series (Fifth Generation) Injection Molding Machine

Fu Chun Shin FB-R Series (Fifth Generation) Injection Molding MachineTo further enhance energy-saving effectiveness, a new clamping mechanism has been introduced, increasing overall rigidity by 15%. After upgrading the turntable specifications, the mold load capacity has been enhanced by 10%, and equipped with a high-end electric turntable, the production speed has increased by 10%. Additionally, in the detailed design, the ejector and toggle use lubricated steel pipes, the clamping unit is carefully equipped with linear guides, and the non-contact design between the moving mold and the large columns has improved the mold opening and closing speed by 15%. Furthermore, the hydraulic seat's forward and backward movements also utilize a linear rail structure for more precise control, and the injection unit is equipped with linear guides.Ultimately, it can achieve a 10% energy saving.

To address the damage caused by bubbles generated due to negative pressure when the oil pump draws oil, affecting the oil pump and various hydraulic components, the entire machine's electro-hydraulic servo unit adopts an oil circuit control method with return oil filtration. This effectively enhances energy conversion efficiency, making the injection molding process smoother.

In terms of product precision,Fuqiangxin FB-R SeriesBy using a shared rectifier unit to power both the integrated electro-hydraulic servo unit and the electrified injection molding unit, it is possible to control each inverter unit and servo motor to execute action commands via the host computer, thereby improving product accuracy and stability, as well as injection repeat positioning.Accuracy up to 0.01mm。

FB-R Series Injection Molding MachineIn order to further enhance the convenience of human-machine operation, the system has undergone a comprehensive upgrade, optimizing the user interface (UI) and operational experience, and adding multiple new functions. This not only improves the device's accuracy and response speed (by 20%) but also enables real-time energy consumption display and optimization, making the entire machine more energy-efficient. After a comprehensive upgrade of the power system,The overall system pressure is increased by 50%.

FB-R Series (Fifth Generation) Injection Molding MachineIn terms of exterior design, the original high-quality texture and durability have been maintained. The overall dimensions of the unit occupy the same floor space as models with the same specifications.decreased by 15%Ergonomic sheet metal modular design facilitates equipment maintenance; the piping adopts a new technology with a weld-free design, making the entire machine more environmentally friendly, safe, stable, and reliable.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics