Boster and Kurz announced a strategic partnership to jointly advance hot stamping technology!

Recently,博斯特 and 库尔兹 have decided to deepen their partnership by jointly showcasing the NOVAFOIL 106 H hot stamping machine at Kurz's demonstration center in Fürth, Germany. By deploying this highly specialized hot stamping equipment at the Kurz demonstration center, both parties expect to use this as an opportunity to promote innovation and development in hot stamping technology, ultimately transforming the landscape of the packaging decoration industry.

Bost also, as an industry leader providing substrate treatment, printing, and processing equipment and services for packaging and labeling manufacturers, has decided to further deepen its cooperation with Kurz, a global leader in surface decoration technology. The goal of this collaboration is to fully integrate and leverage the expertise and innovation capabilities of both companies in their respective fields to jointly expand the application areas of hot stamping technology.

Through a strong alliance, both parties will work together to promote the in-depth development of hot stamping technology, better meeting the growing market demand for high-end packaging decoration. It is expected that this cooperation will yield remarkable results, benefiting customers and the entire industry. This collaboration will focus on the research and development and testing of cutting-edge technologies. In the initial testing phase, both parties will focus on evaluating various improvement plans oriented towards customer needs and are committed to providing highly customized solutions for customers.

As an integral part of the collaboration plan between both parties, an advanced NOVAFOIL 106 H hot stamping machine has been successfully installed at Kurz's demonstration center in Fürth. The NOVAFOIL 106 hot stamping machine, crafted by Bobst, is designed to comprehensively enhance the decorative functions of packaging boxes and is equipped with a newly designed hot stamping platform. This compact hot stamping equipment ingeniously integrates longer dwell time, stable temperature control, and higher hot stamping pressure with Bobst's unique non-paper-contact ACCUREGISTER electronic registration system, ensuring exceptional hot stamping accuracy and decorative quality on paperboards with a maximum format of 1060 millimeters.

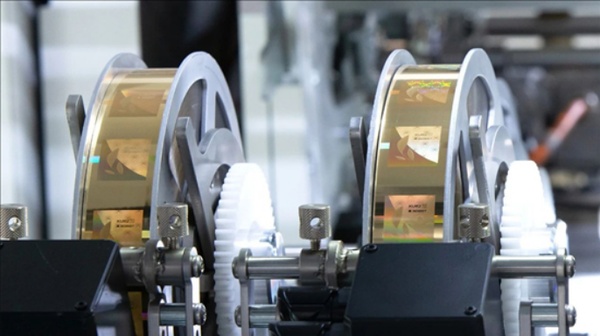

It is worth mentioning that the NOVAFOIL 106 hot stamping machine can be equipped with a transverse stamping module, enabling more complex and refined decorative effects in a single pass. At Kurz’s demonstration center in Fürth, visitors even have the opportunity to experience and test the newly launched holographic application equipment—NOVAFOIL 106 H. This machine can accommodate up to ten dedicated holographic modules, making it a unique and highly efficient holographic application tool that effectively supports brand protection and anti-counterfeiting efforts.

In order to maximize the operational flexibility of the equipment, these modules can be flexibly installed individually on two horizontal rails according to actual production needs, and easily connected to the machinery through a convenient "plug-and-play" system. Each module is equipped with an independent motor and braking system, along with an independent aligning device configured for each film roll, ensuring higher precision in the hot stamping application.

Since the equipment can simultaneously run up to ten modules, processors are able to complete highly complex holographic designs in a single pass, thereby maximizing production efficiency and capacity. Mr. Bodo Junge, Product Marketing Director of BOBST's hot stamping division, stated: "We are delighted to collaborate with Kurz to showcase this outstanding equipment at the Kurz Demo Center. This partnership allows us to deepen our relationship, create synergies, and jointly develop exciting innovative technologies." Both companies have high expectations for the market innovation potential brought by this collaboration.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track