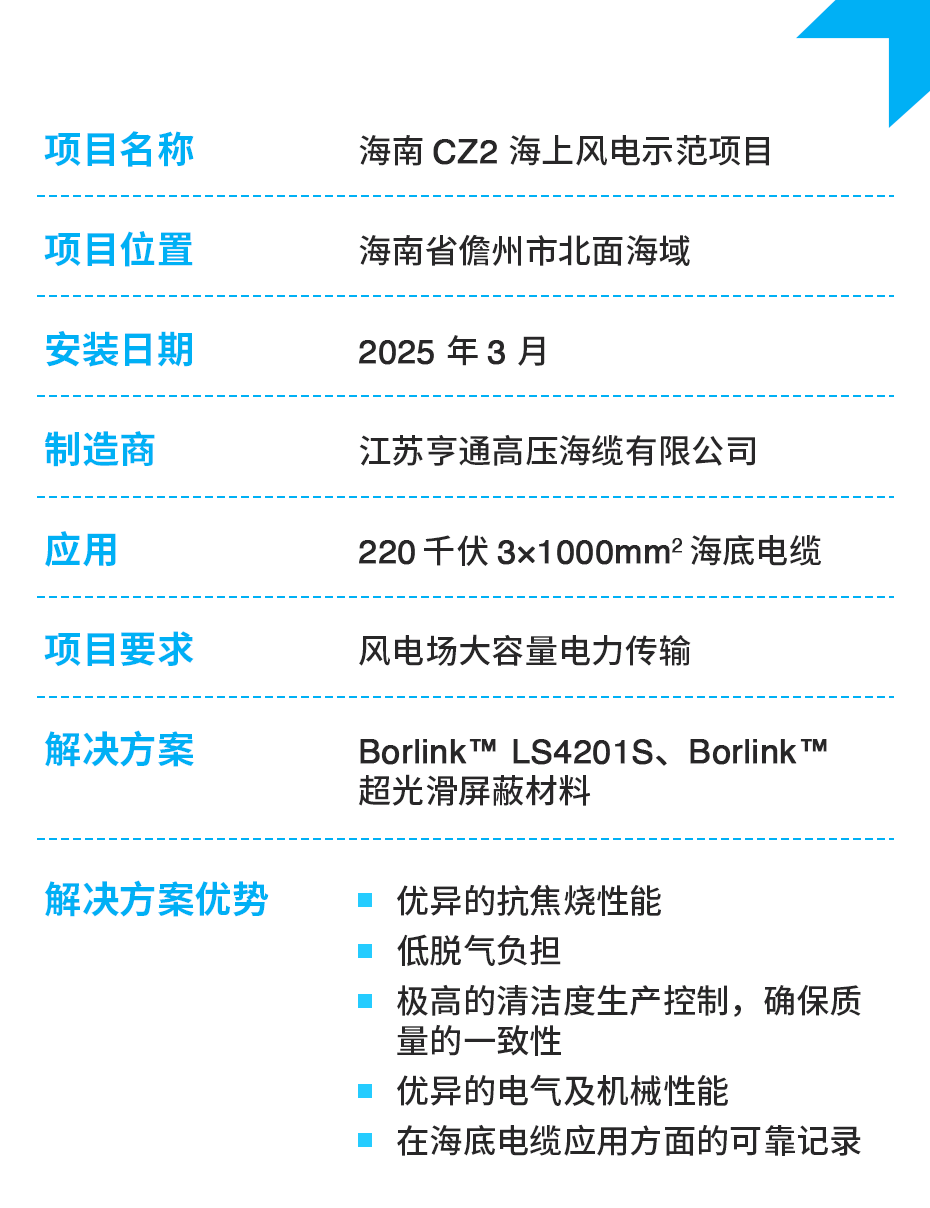

Bolu And Nordic Chemical Support Implementation Of Hainan Province’s First Full-Capacity Grid-Connected Offshore Wind Power Project

Project Overview

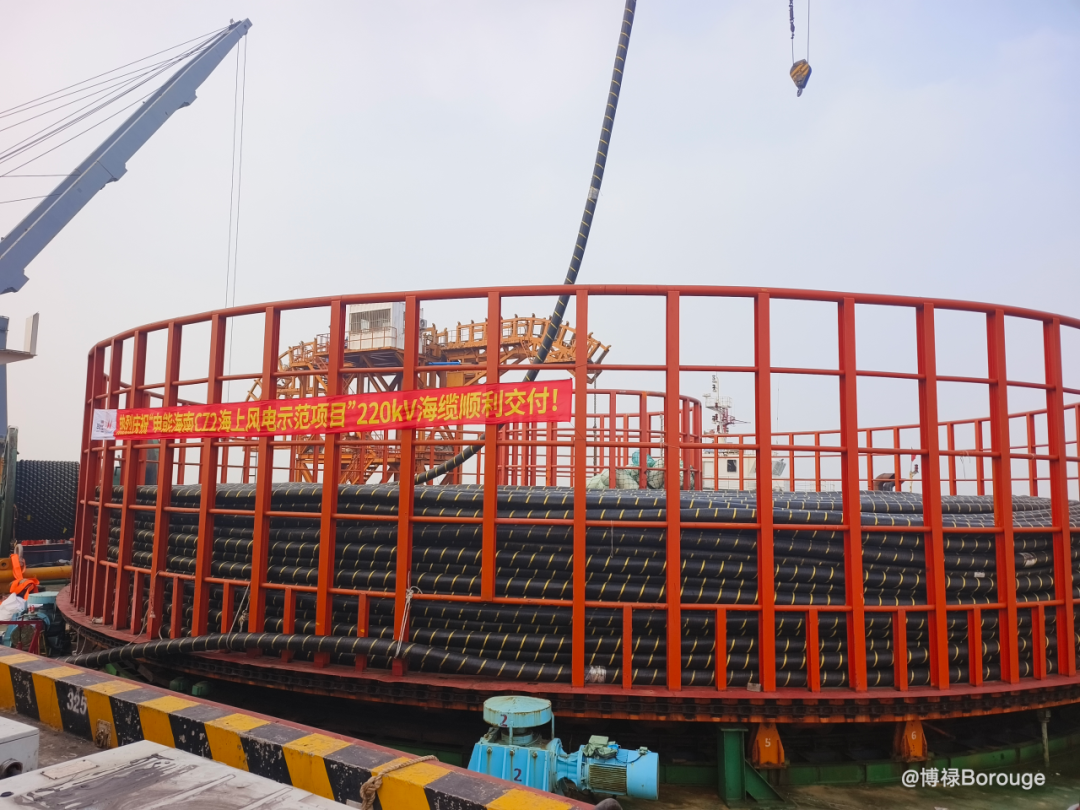

Image 1: Loading of three-core 220kV submarine power cable onto the ship

(Provided by Jiangsu Hengtong High Voltage Submarine Cable Co., Ltd.)

The Hainan CZ2 Offshore Wind Power Demonstration Project site is located in the northern sea area of Danzhou City, Hainan Province, with an average water depth of 20 meters, a center distance of about 27 kilometers offshore, and a site area of approximately 191 square kilometers. The project has a total installed capacity of 1.2 million kilowatts, supporting the construction of two 220 kV offshore booster stations and one onshore centralized control center (located in Eman Town, Danzhou City), with a total investment of 15 billion yuan. In March this year, the first phase of the project achieved full-capacity grid connection and power generation, becoming the first offshore wind power project in Hainan Province to achieve full-capacity grid connection and power generation during the 14th Five-Year Plan period.

The CZ2 project is Hainan Province's first offshore wind power project to receive approval from the Ministry of Natural Resources and the first to receive official national approval to commence construction.Since the commencement of construction on January 28, 2024, facing multiple difficulties and challenges such as frequent typhoons, cold wave monsoons, complex maritime geology, and the high technical difficulty of directional drilling, the project team has united sincerely, focused on tackling key problems, and seized construction windows, continuously optimizing design plans and construction techniques to promote the project construction with high quality and efficiency.

Project Significance

Upon full completion, the Hainan CZ2 Offshore Wind Power Demonstration Project will be capable of delivering 3.82 billion kilowatt-hours of clean electricity annually. This is equivalent to saving 1.15 million tons of standard coal, reducing nitrogen oxides emissions by approximately 14,000 tons, and cutting carbon dioxide emissions by about 2.99 million tons. The first phase of the CZ2 project has an installed capacity of 600,000 kilowatts, and once operational, it will generate about 1.9 billion kilowatt-hours of electricity annually, sufficient to meet the annual electricity needs of approximately one million households.

In terms of economic benefits, the CZ2 project can drive the transformation of the local energy structure and the low-carbon upgrading of industries, injecting strong green momentum into the construction of the Hainan Free Trade Port and the "Clean Energy Island," thereby promoting local economic development.

Image 2: Cable Laying of Hainan CZ2 Offshore Wind Power Demonstration Project

(Provided by Jiangsu Hengtong High Voltage Submarine Cable Co., Ltd.)

Your Trusted Cable Solutions Partner

Following the successful cooperation on several important projects, such as the 220kV submarine cable project for the Bohai-Zhongkenli oilfield group's shore power application project, Jiangsu Hengtong High Voltage Submarine Cable Co., Ltd. has once again chosen to collaborate with Borouge and Borealis.The Hainan CZ2 offshore wind power demonstration project uses products manufactured by Borouge in the UAE.Borlink™ LS4201S...used for the production of 220kV 3×1000mm2The insulation layer of the main cable is made of high-voltage ultra-high purity low-density polyethylene insulation material, tailored based on the Borlink™ technology platform developed and licensed by Borealis. The closed-loop cross-linked polyethylene and post-impregnation process of Borouge and Borealis ensure the ultra-high purity and batch consistency of the product, thereby ensuring the safety and reliability of long-length submarine cable production.The maximum length of a single submarine cable in this project is approximately 33 kilometers, containing only one joint.

The inner and outer screens of the 220kV submarine cable use Borealis Borlink™ super-smooth shielding materials from Borealis, whose excellent smoothness, processing, and electrical properties bring numerous performance advantages to cross-linked polyethylene cable manufacturers. When used in conjunction with Borlink™ LS4201S, it can be widely applied to 220kV submarine cables to achieve continuous long-length operation.

Project Summary

Wen: Zhou Yue

Senior Engineer in Energy Application Development

Borealis Energy & Infrastructure Business Unit, North Asia

Learn more

Borouge website:

www.borouge.com

Borealis website:

www.borealisgroup.com

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track