Bole Intelligence to Attend 2025 National Magnesium Industry Conference, Leading a New Era in Magnesium Alloy Manufacturing with Innovative Technology

To accelerate the construction of a modern magnesium industry system, expand the application boundaries of magnesium alloys, and promote the high-quality development of the magnesium industry, the 2025 National Magnesium Industry Conference and the 28th Annual Meeting of the Magnesium Branch of the China Nonferrous Metals Industry Association were held in Yuncheng, Shanxi Province from October 20 to 21. BoLe Intelligent was invited to participate in this conference, taking on the role of a "technical breakthrough maker" to jointly outline the grand blueprint of "Magnesium Gathering in Yuncheng · Intelligent Chain for the Future" with the industry.

01

Technological innovation

Semi-solid forming technology reshapes industry benchmarks.

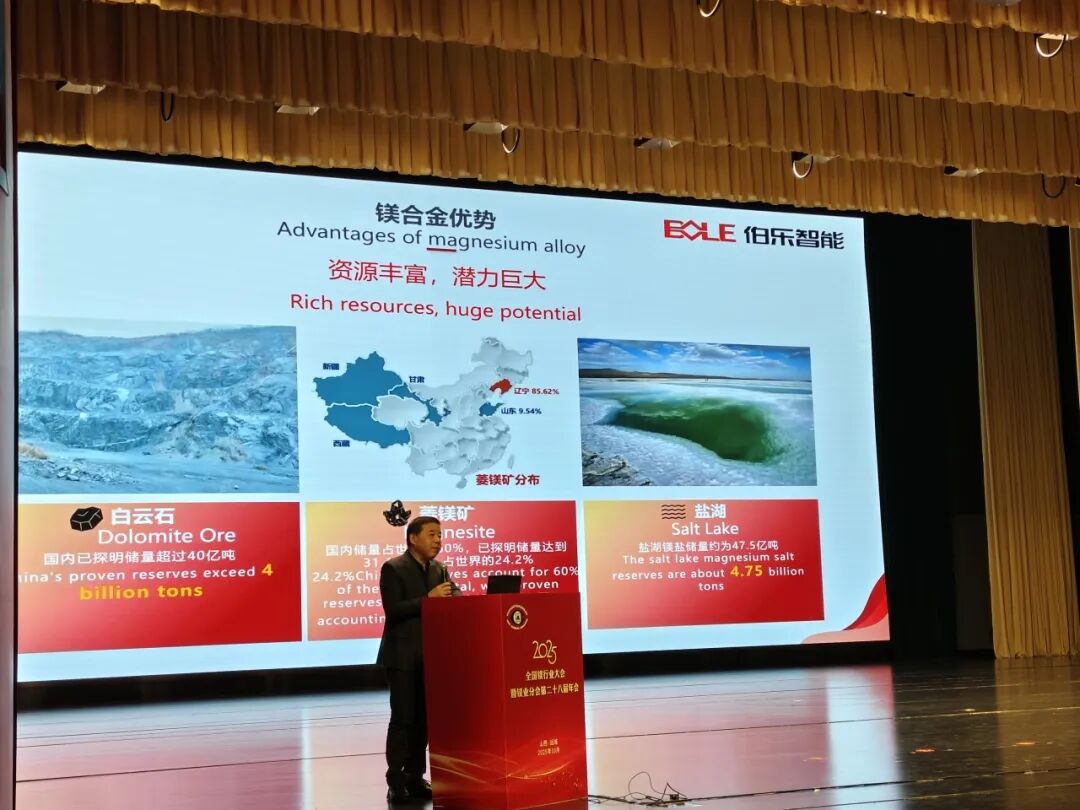

Chairman Wei-liang Kui of Bole Intelligent gives a presentation.

In the thematic report session, Mr. Kui Weiliang, Chairman of BoLe Intelligent Equipment Co., Ltd., shared a report on the theme of "Magnesium Alloy Semi-Solid Injection Molding Technology." He provided a detailed introduction to the principles and advantages of this technology, as well as application cases in multiple industrial fields, focusing on innovative applications of magnesium alloys in automotive lightweighting, aerospace, 3C electronics, humanoid robots, low-altitude economy, and biomedical fields. Experts and scholars attending the session shared their insights on the overall development trend of the magnesium industry, the current status and prospects of magnesium applications, directions for technological breakthroughs, and market potential demands, drawing from their own research results and practical experiences.

02

Industry Leadership

Comprehensive leadership from device to product.

As a pioneer in the field of semi-solid forming of magnesium alloys, Bole Intelligent's technological strength has been highly recognized by the industry.

Device Matrix:We have launched a full range of magnesium alloy injection molding equipment from 300 to 4000 tons and have completed the production of 17KG magnesium alloy products with a maximum injection capacity of 35KG. This enables the lightweight integration molding of large structural components, advancing the process of "replacing aluminum with magnesium" in the bodies and chassis of new energy vehicles.

Standard Formulation:Led the drafting of multiple industry standards for semi-solid forming of magnesium alloys, with technical parameters becoming the selection criteria for global customers.

Energy Efficiency LeapThrough the deep coupling design of servo motors and hydraulic systems, paired with patented software algorithms, the energy consumption of the equipment is reduced by 35% compared to traditional die casting. The annual electricity savings of a single unit equate to a reduction of 800 tons of carbon emissions, directly addressing international green barriers such as the EU Carbon Border Adjustment Mechanism (CBAM).

Industrial Green and Low-Carbon Transition

Intelligent upgrade

03

Discussing the Future

Chain Global, Defining a Lightweight Future

The theme of this conference is "Accelerating the Construction of a Modern Magnesium Industry System, Expanding the Application Boundaries of Magnesium Alloys, and Promoting High-Quality Development of the Magnesium Industry." The participation of Bole Intelligence highlights the core position of Chinese enterprises in the global magnesium industry chain. From Yuncheng to the global stage, from equipment supplier to ecosystem builder, every step of Bole Intelligence marks the rise of China's magnesium industry. In this industrial transformation, where technology is the pen and ecology is the ink, Bole Intelligence is joining hands with industry partners to jointly write a magnificent chapter of the "Magnesium Era."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track