Biobased pc breakthrough: The Race to High-End Development to Eliminate "BPA Dependency" Begins

Recently, at the 7th New Materials Industry Expo, an innovative achievement has drawn widespread attention in the industry—the official unveiling of China’s first set of bio-based polycarbonate (PC). The production facility for this material was jointly constructed by Kunlun Engineering Company, a subsidiary of China National Petroleum Corporation, and Puyang Shengtong Juyuan New Materials Co., Ltd. It successfully commenced operations in February of the same year, with an annual production capacity of 5,000 tons, filling the gap in domestic bio-based PC production.

In the context of the chemical new materials industry continuously advancing towards high performance, green low-carbonization, and intelligence, bio-based PC is rapidly becoming a highly regarded emerging track.

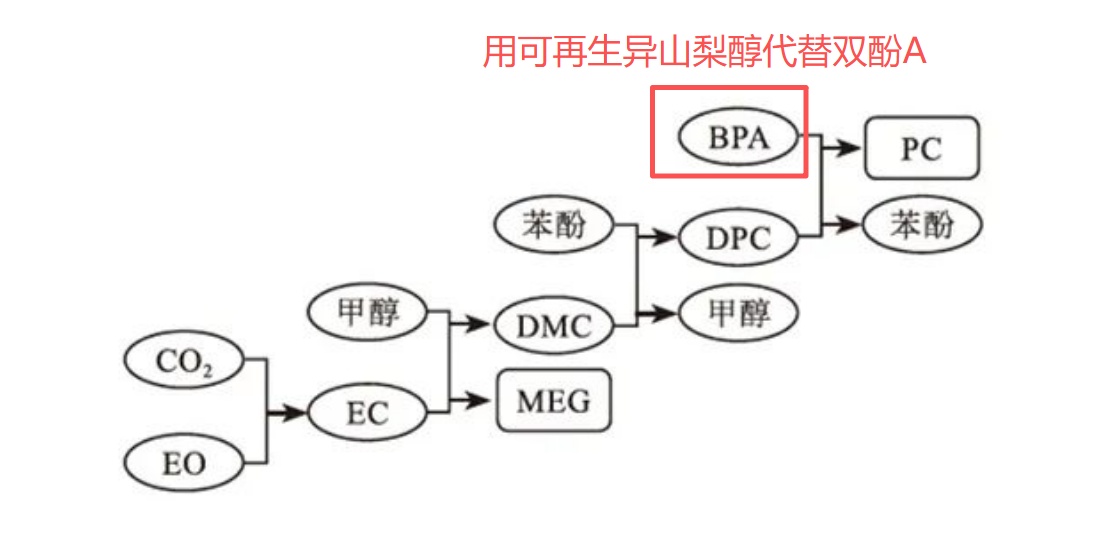

Diagram Bio-based PC - Isosorbide-type PC (Image source: Sheng Tong Ju Yuan)

01 Breaking Monopoly: From Catching Up to Leading, Bio-based PCAchieve localization

Biobased PC is not a completely new concept, but it has long been dominated by foreign giants. Japanese companies Mitsubishi Chemical, Covestro, and Teijin have always been at the forefront globally.

As early as 2015, Mitsubishi Chemical has mass-produced the DURABIO series products using isosorbide as a bio-based monomer, which are widely used in automotive parts. Covestro has launched "bio-based Makrolon®" with 60% bio-based carbon content for use in eyeglass lenses. The Teijin Group has developed 100% bio-based PC and plans to start mass production before 2025.

In 2024, China, as the world's largest PC manufacturer, will have a production capacity of 3.81 million tons, accounting for 48% of the global total production capacity.High-end product 70%Depend on importsIncluding high value-added products such as optical grade and medical grade.

The cooperation project between Shengtong Juyuan and Kunlun Engineering has successfully broken this situation, opening up the possibility for the commercialization of bio-based PC in the domestic market.

This is inseparable from the new development strategy of China National Petroleum Corporation. On August 21, 2025, Dai Houliang, Chairman of China National Petroleum Corporation, presided over the meeting of the leading group for carbon peaking, carbon neutrality, and emerging industries, clearly outlining the three-step overall plan: "clean replacement, strategic succession, green transformation."

He emphasized that while consolidating and developing the oil and gas industry chain, it is important to accelerate the development of emerging industries such as "thermal power hydrogen" and "bio-based refined materials," as well as to layout future industries. Among them, "bio-based refined materials" includes biotechnology, fine chemicals, and new materials, which have higher technological content and added value.

In terms of new materials, PetroChina is actively involved in the research and production of key materials including high-end polyolefins, specialty fibers, high-performance synthetic rubber, and specialty lubricants. The independent metallocene catalyst has achieved a breakthrough in large-scale industrial application, and the complete technology for producing nylon 66 using benzene as the sole raw material has achieved a significant breakthrough.

02 Technology Breakthrough: Replacing Bisphenol AInnovative bisfuran ring structure

The core breakthrough of bio-based PC lies in raw material substitution and structural innovation. The traditional PC raw material bisphenol A (BPA) poses health risks, and many countries, including the European Union, have imposed strict restrictions on its use in food packaging and other fields.

The project uses renewable isosorbide as a bio-based monomer to replace the copolymer monomer bisphenol A, introducing a unique bifuran ring structure into the polymer product. This innovation brings multiple advantages: surface hardness close to glass, processing fluidity comparable to general PC, and a light transmittance of up to 92%.

Due to the reduction of benzene rings in the molecular structure,The product is not prone to absorb ultraviolet rays.In fields such as optical lenses and automotive interior and exterior components, it shows broad prospects. More importantly, it avoids the health risks associated with bisphenol A and can precisely target the trillion-level application markets of food packaging and medical devices.

Technical challenges include: designing highly active catalytic systems to overcome the low reactivity bottleneck of isosorbide, enhancing precise control of devolatilization and chain growth during the melt polycondensation process, and precisely regulating copolymer structure to balance heat resistance and processability.

03 Process Route: The Green Non-phosgene Method Becomes Mainstream

The synthesis of polycarbonate (PC) is usually divided into two processes: phosgene method and non-phosgene method. Interfacial polymerization is currently the most commonly used phosgene method, with a mature process, stable production, and ease of control.

The non-phosgene method, as a "green process," is increasingly favored. It involves a transesterification reaction between dimethyl carbonate and phenol to produce diphenyl carbonate, which then undergoes transesterification and polycondensation reactions with bisphenol A to generate polycarbonate.Not using toxic phosgene as a raw material is safer for both the environment and the operators.

In 2017, Sheng Tong Ju Yuan invested 1.95 billion yuan to construct the first phase of a polycarbonate project with an annual capacity of 130,000 tons, utilizing the "non-phosgene melt transesterification method" production technology with independent intellectual property rights. It is one of the first companies in China to master this technology.

Diagram of the non-phosgene melt transesterification process for PC technology. The bio-based PC technology mentioned in this article uses renewable isosorbide instead of bisphenol A (Image source: China Synthetic Resin Association).

In February 2025, the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences successfully developed a high-performance catalyst for the synthesis of polycarbonate, using a green and environmentally friendly route. Dimethyl carbonate was produced through methanol oxidative carbonylation, which was then used to synthesize polycarbonate, achieving industrial application in a domestic enterprise with a production capacity of 260,000 tons per year.

04 Market landscape: coexistence of overcapacity and insufficient high-end production.

In 2024, the global PC production capacity will grow to around 7.8 million tons per year, with China's PC industry showing rapid development. By the end of 2024, the total domestic production capacity will reach 3.81 million tons, with an output of 2.3 million tons, accounting for almost half of the global production capacity.

As of the end of 2024, the total domestic PC production capacity will reach 3.81 million tons (Source: Longzhong).

In the past five years, China's PC production capacity has increased.The production capacity of the non-phosgene method has significantly improved.Currently, it has become the most important PC production process in the country, accounting for nearly 50%. In addition, there are over 2 million tons of projects under construction and planned, intensifying market competition.

Table: China's PC projects under construction and planned exceed 2 million tons (Source: Chemical New Materials)

Although China's PC production capacity ranks first in the world, with an import volume of 887,300 tons and an export volume of 487,100 tons in 2024, and an import dependency rate reduced to 24.7%, high-performance and specialized PC products still need to be imported.

The structural contradiction of high-end insufficiency and low-end surplus is prominent. Therefore, bio-based PC is not a direct replacement for traditional PC. It needs to upgrade and move towards high-end in certain aspects to escape the fate of struggling at the low-end.

05 Application prospects: Great potential in three major high-end fields

In the face of intense market competition, during the "15th Five-Year Plan" period, the PC industry will focus on high-end products: medical-grade PCs, optical-grade PCs, and special specification PCs, among others.

Medical-grade PCThese can be used in the field of medical devices (such as syringes, blood dialysis devices, surgical instruments, etc.), diagnostic equipment, artificial organs, and so on. These types of products need to undergo rigorous biocompatibility testing and FDA certification, which have longer cycles and higher barriers.

Optical-grade PCThe requirement for light transmission rate needs to reach 92% or even higher, requiring nanoscale control technology. It is widely used in fields such as optical lenses, display panels, and LED light covers. On August 27, 2025, Wanhua Chemical and Geely Automotive jointly released the automotive-grade light-guiding PC material Clarnate® LED1355, marking Wanhua Chemical as the first Chinese company to enter the core supply chain of light-guiding materials for Geely Automotive's car lights.

Special grade PCFlame-retardant PC and bio-based PC are worth noting. Flame-retardant PC is primarily used in electronic appliance housings and automotive components; bio-based PC, as a green and environmentally friendly specialty material, is expected to quickly replace traditional products in fields such as food contact and medical applications.

06 Future Challenges: Cost Control and High-end Breakthroughs

One of the biggest challenges faced by bio-based PC is the cost issue. How renewable isosorbide can compete with the current 8,200 yuan/ton BPA is a problem that the industry chain must solve.

Not only is technological innovation needed, but also economies of scale and process optimization. The Shengtong Juyuan Phase II project is a 54,000-ton/year specialty polymer project under construction in collaboration with PetroChina, which includes several directions such as low melt index PC side-line projects, bio-based PC projects, and PPS projects. This diversified layout helps to share R&D and production costs.

On the other hand, bio-based PC needs to continuously develop towards high-end markets to avoid falling into the trap of low-end price wars. By enhancing product performance and entering high value-added application fields, true value breakthroughs can be achieved.

Editor: Lily

Source materials: Chemical New Materials, China Synthetic Resin Association, DT New Materials, RIC Consulting, etc.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track