BASF's 10,000 R&D personnel will focus on these three directions in the future!

In 2024, BASF achieved sales of approximately 11 billion euros (about 863 billion RMB) through research and development products launched over the past five years. This data has been included in BASF's 2024 annual report, which will be released on March 21, 2025.

Dr. Stephan Kothrade, member of the BASF Executive Board and Chief Technology Officer, stated: "Our long-term goal is to further enhance the sales and profitability of innovative and improved products—especially those that drive sustainable technologies."

In 2024, BASF continued to maintain its leading position in the chemical industry in terms of both the quantity and quality of patents, submitting 1,159 new patent applications throughout the year, with approximately 45% specifically focusing on the field of sustainable development.

Despite facing economic challenges, BASF's R&D investment for 2024 remains at a high level of 2.1 billion euros, continuing to lead the industry. The company plans to maintain the same scale of R&D budget in 2025.

"Innovation is the key to achieving our 'Winning Path' new strategic goals. Our product and process innovations not only help our customers succeed in the market but also assist them in reaching their sustainable development goals," said Cotrade.

Future R&D work will focus on green transformation technologies, including biodegradable materials, sustainable value chain processes, and innovative solutions for the plastic circular economy. The company will also accelerate digital transformation—applying digital tools in R&D to bring more advanced technologies to market at a faster pace.

BASF launched a series of innovative products in 2024 focusing on sustainability, materials innovation, and agricultural technology. Below are detailed introductions to the main products.

Sustainable Materials and Circular Economy

Ultramid® Ccycled® polyamide: Utilizing chemical recycling technology, post-consumer plastic waste (such as used tires) is converted into pyrolysis oil, which serves as a raw material for production. Certified through a mass balance approach, it effectively reduces carbon footprint while ensuring product performance is consistent with traditional polyamides.

VAUDE outdoor pants made from Ultramid recycled material

"Design for Recycling" PU foam technology: The recycling process of polyurethane foam has been optimized to achieve streamlined recycling, further promoting the plastic industry towards the direction of a circular economy.

LooPamid® Polyamide 6: This is the world's first polyamide 6 produced entirely from textile waste, suitable for the production of clothing and accessories. This technology enables the recycling and reuse of industrial textile waste as well as old garments, and supports multiple cycles of reuse.

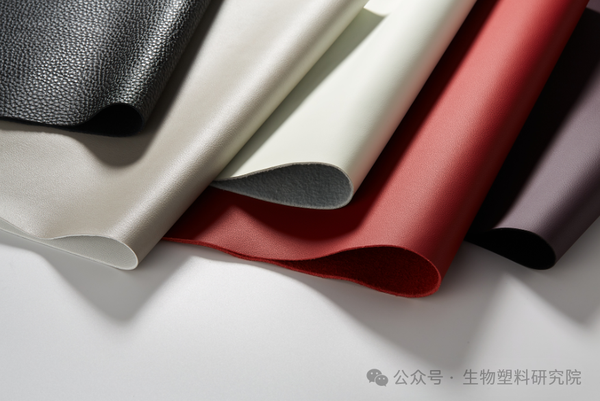

Haptex® 4.0 polyurethane synthetic leather: Through innovative formula design, this synthetic leather can achieve 100% recycling without the need for interlayer delamination. It has excellent heat resistance and yellowing resistance, and the production process does not use organic solvents, making it both environmentally friendly and economical.

IrgaCycle® additive series: primarily used to enhance the quality and efficiency of plastic recycling, playing an important role in the mechanical recycling process. For example, it can help convert discarded fishing nets into car speaker frames and upgrade plastic pallets into storage boxes.

Agricultural Science and Technology

Mibelya fungicide: composed of fluopyram and chlorothalonil, it is effective in controlling diseases such as black spot and anthracnose on crops like tomatoes, apples, and potatoes.

Vinquo Insecticide: With bifenthrin as the active ingredient, it has a unique mode of action against piercing-sucking pests such as whiteflies on tomatoes and potatoes, helping to delay the development of resistance.

Revy Lok™ bactericide: specifically designed for soybean cultivation, effectively controls diseases such as Phakopsora leaf spot and gray spot, thereby increasing soybean yield.

Axant™ Flex Cotton Trait System: Combines a new herbicide resistance gene with high-quality cotton varieties to provide cotton farmers with a more flexible weed management solution.

Endura Pro fungicide: primarily used for the control of diseases in potatoes, effectively resisting early blight and white mold, helping to improve potato yields.

Other innovative products

Elastollan® bio-based TPU: While maintaining the same mechanical properties as traditional thermoplastic polyurethane, it is made from bio-based raw materials and can be used in the production of textile fibers and non-woven fabrics.

Blockchain Tracking Cotton (CSF): In collaboration with partners in Greece, we have developed a transparent blockchain platform that tracks the carbon footprint of cotton from seed to stitching and supports the production of regenerated cotton.

Fiber bonding technology: It can transform waste materials such as coffee grounds and paper cups into building materials or industrial materials, for example, flooring made from denim waste.

Automotive paint ChemCycling® clear coat: produced using chemical recycling technology, it can reduce CO₂ emissions and enhance the sustainability of the automotive refinish industry.

Personal Care Innovation: Launched Epi Spot™ active ingredient, extracted from willow bark, to improve sensitive skin and regulate sebum production; simultaneously developed AI-driven silicone alternatives and a digital formula management platform.

These innovative products fully demonstrate BASF's comprehensive strength in materials science, agricultural technology, and sustainable development, providing strong support for various industries to address environmental challenges through technological breakthroughs.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track