BASF Signs National "Little Giant" Humanoid Robot, Saudi Aramco Invests!

[DT New Materials] has learned that on August 18, BASF announced that the company has signed a Memorandum of Understanding (MoU) with Shanghai Fourier Intelligence Co., Ltd. (Fourier). The aim is to evaluate and develop new material solutions for various robotic applications and to jointly explore the application and development of engineering plastics, polyurethanes, and thermoplastic polyurethanes in robots and their components, while establishing cooperation in technology, commerce, market, and business models.

This is another new development by BASF following their showcase at this year's International Rubber & Plastics Exhibition, where they demonstrated the application of high-temperature nylon in robotic arms and TPU in industrial robot cables. The previous showcase was in 2017, featuring an industrial collaborative robot developed in cooperation with China’s Siasun, which utilized BASF's Elastollan® thermoplastic polyurethane elastomers, Ultramid® glass fiber reinforced polyamides, and 3D printed polyamide-6 materials to improve production efficiency and reduce energy costs.

This collaboration marks the second major hot sector that BASF has entered after solid-state batteries. The next one should be the low-altitude economy.

First, let's talk about this partner company; it has quite a background.

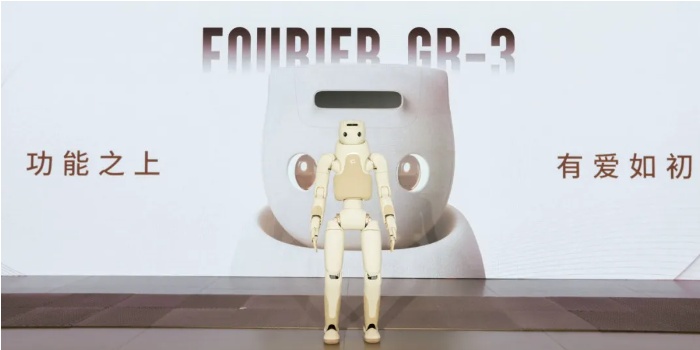

Fourier was established on July 30, 2015, and is headquartered in Pudong New District, Shanghai. Based on full-stack robotic core technology, it has developed various medical rehabilitation products such as upper limb rehabilitation robots and exoskeleton robots. Its business covers more than 40 countries and regions worldwide. It is a leading enterprise in the field of humanoid robots in China and a national key "Little Giant" enterprise.

As of 2025, the company has completed 13 rounds of financing, with a total amount exceeding 1.6 billion RMB. The participating institutions are quite prestigious, including IDG Capital, Qianhai Mother Fund, Sequoia China, Lingang Sci-Tech Venture Capital, Pudong Venture Capital Group, SoftBank Group, Prosperity7 Ventures (a fund under Saudi Aramco), among others. Recently, it also completed a 300 million RMB investment involving Zhejiang Runyang New Material, a listed company in the foamed materials sector.

The cooperation signing was initiated and promoted by BASF Venture Capital (BVC), the venture capital arm of BASF Group. This marks the department's first collaboration in the robotics industry in China. Future investment possibilities cannot be ruled out.

When it comes to humanoid robots using polymer materials, it is already familiar, and many companies have announced their plans in this area, including Kingfa Sci & Tech, Pret, Huitong Co., Silver Jubilee Technologies, Dawn, etc.

Relevant material applications include, for example, radar housings: PBT + glass fiber; memory/processor connectors: LCP; masks: high-transparency acrylic, PC, or transparent nylon; camera modules/visual sensors: PMMA/COC; thoracic/internal supports: continuous fiber-reinforced composites; joint/bone structures: PA66 or PPA with short glass fiber or continuous fiber; dexterous hand skin: TPU; connecting rods: continuous fiber-reinforced composites; battery pack housings: fiber-reinforced PC; actuator gears, bearings: PEEK; housings/decorative parts: ABS, PC/ABS; tendon ropes: ultra-high molecular weight polyethylene.

Polyurethane is an ideal base material for electronic skin and can also be used as a bionic skin material for humanoid robots. It can be fabricated into honeycomb or porous structures, which reduces weight while improving flexural strength. Polyurethane is used in robot joint seals, foot pads, and arm modules to replace some aluminum components, as well as in knee joint cushioning layers and robot cable coatings. In China, companies with a clear focus on polyurethane materials for robotics include Hongbaoli (bionic skeletons), Youbaite (special-shaped tracks), Lun Polyurethane (Mecanum wheels), and Ketian Group (skin materials).

In addition, Fourier’s new products have incorporated “Good Foam” (GFOAM) from its new shareholder Runyang Technology. This material is produced using electron cross-linked polyolefin foam technology and features non-toxicity, environmental friendliness, high resilience, thermal insulation, sound insulation, and shock absorption. It can be used to cover the robot’s arms, legs, torso, and even intricate areas such as the face, ultimately enabling full-body coverage.

Wang Xingxing from Unitree Robotics recently stated that the entire robotics industry was booming in the first half of this year. Component manufacturers, in particular, experienced an average growth of nearly 50% to 100% for each company, which is quite rare for the industry, driven by demand. In the coming years, the annual shipment volume of humanoid robots in the entire industry is guaranteed to double each year. With significant technological breakthroughs, it is even possible that in the next 2 to 3 years, the annual shipments could suddenly reach hundreds of thousands, or even millions of units.

This will also provide polymer material companies with a brand-new large market.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track