BASF: Plant Races to Production + New Technology Globally First!

Recently, BASF has achieved significant progress in its industrial layout and technological innovation in China: on one hand, the BASF Zhanjiang Verbund site has completed two major milestones, the commissioning of the butyl acrylate plant and the mechanical completion of the ethylene joint venture plant and petrochemical plant, advancing towards the goal of full operations by the end of 2025; on the other hand, its Chemetall business unit has launched the world's first chromium-free and fluorine-free copper foil passivation solution, providing a new environmentally friendly and high-performance option for the new energy battery materials field.

BASF Zhanjiang Integrated Base: Key Units Commissioned and Mechanically Completed, Sprinting Towards Full Operation by Year-End

On October 7th, BASF's Zhanjiang Verbund site announced two significant developments, marking the construction of this world-class production base entering the final stages, laying the foundation for full production by the end of 2025.

Acrylic acid butyl ester unit started production ahead of schedule, achieving the first customer delivery.

On August 11, 2025, BASF's Zhanjiang Verbund site officially commenced operations of its butyl acrylate plant, completing ahead of the original schedule while maintaining a record of zero safety incidents throughout the process. On August 17, the plant completed its first delivery of butyl acrylate via tank truck, marking the first customer fulfillment post-commissioning. According to public information, the butyl acrylate plant has a designed annual capacity of approximately 400,000 tons. The product will be used in the adhesive, industrial coatings, and architectural coatings industries, providing key raw materials for customers in these sectors, further strengthening BASF's position in the acrylic market.

The ethylene joint venture and petrochemical plant have completed mechanical completion.

During the same period, the core ethylene joint unit (with a designed annual capacity of 1 million tons) and all downstream petrochemical units (including ethylene oxide, oxo-alcohols, syngas, and high-density polyethylene units) at the Zhanjiang integrated base have fully completed mechanical completion. This milestone signifies that all equipment installation, system connections, and testing work for the aforementioned units have been completed, marking the transition of the project from the construction phase to the operational readiness phase. This provides assurance for the commissioning and start-up work scheduled before the end of 2025.

Bir Darbar Mehta, Senior Vice President of BASF and Head of the Petrochemicals Division in Asia Pacific, stated that the progress of the Zhanjiang integrated site will strengthen BASF's business layout in the Asia Pacific region, enhance production capacity and supply chain resilience, and shorten delivery cycles to customers. Marko Murtonen, Senior Vice President of BASF, General Manager of the new integrated site in China, and BASF Integrated Site (Guangdong) Co., Ltd., noted that the site's progress is thanks to collaboration with partners and local government. In the future, "Made in Zhanjiang" products will serve both local and global markets.

As the core of BASF's strategic layout in the Asia-Pacific region, the Zhanjiang Verbund site is a fully backward-integrated comprehensive base, geographically close to customer groups. Once operational, it will meet the diverse demands for petrochemicals in the Asia-Pacific region.

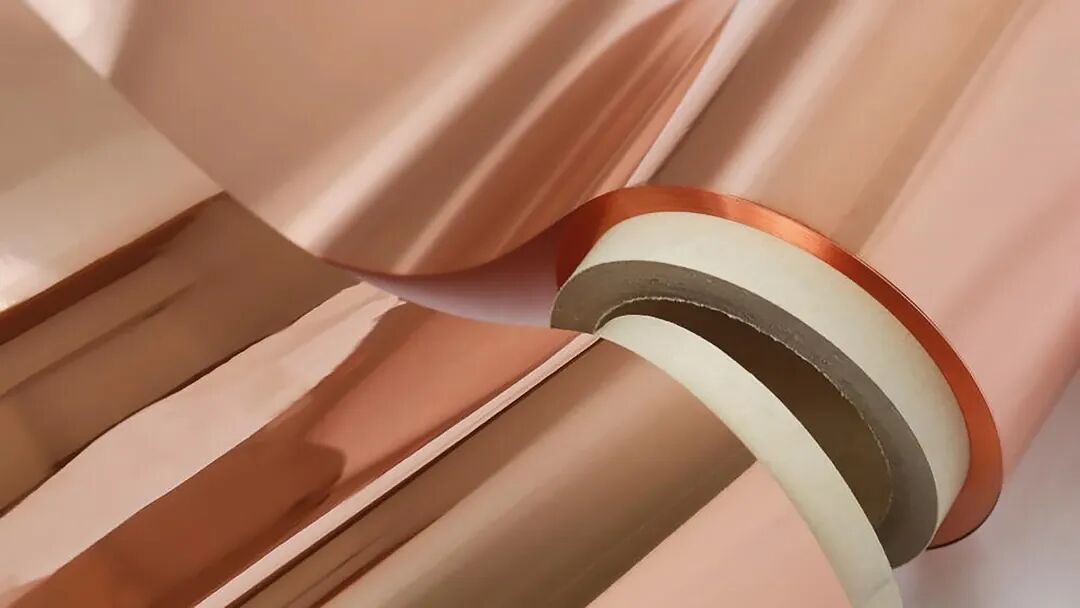

Chemetall launches the world's first chromium-free and fluorine-free copper foil passivation solution, tailored for the needs of new energy batteries.

Chemetall, the surface treatment business unit of BASF, has launched Gardolene® D, the world's first chromate-free and fluoride-free copper foil passivation solution. This solution provides surface treatment support for copper foil used in electric vehicle batteries and energy storage systems, representing an industry-first technology.

1. Technical Features: Dual Advantages of Environmental Compliance and Performance Enhancement

According to the introduction, Gardolene® D achieves "zero addition" of both chromium and fluorine elements, enhancing the surface energy of copper foil, optimizing the adhesion of anode active materials, and simultaneously reducing interfacial resistivity. Tests show that batteries treated with this solution can extend their lifespan by up to 6% and improve capacity retention after 1000 cycles at 25 degrees Celsius, outperforming traditional chromium (VI) passivation processes for copper foil batteries. Moreover, this solution is fully compliant with the new EU Battery Regulation (EU 2023/1542), which requires battery products to declare their carbon footprint, be equipped with a digital battery passport, and enforce strict restrictions on hazardous substances. Starting in 2027, batteries not meeting these standards will be banned from entering the European market. Additionally, Gardolene® D is compatible with existing production equipment, requiring no additional investment for modifications by companies. It is suitable for both electro-deposited and rolled annealed copper foil substrates, covering applications in electric vehicle batteries and various energy storage scenarios.

2. Research and Market Positioning

Chemetall's Global Technology Leader Arjan Termaten stated that the solution was jointly developed by the global R&D and technology teams based on market demand analysis, accumulated surface treatment technology, and customer feedback. It ensures stable copper foil performance, enhances electrode conductivity, and helps manufacturers meet regulatory and sustainability requirements. BASF Coatings' Senior Vice President of Global Surface Treatment Frank Naber pointed out that this solution is a practical example of BASF providing innovative surface treatment solutions for green transformation, aligning with the brand's positioning of "expect more."

The advancement of BASF's Zhanjiang integrated base will supplement the production capacity of high-quality petrochemicals in the Asia-Pacific region, providing essential raw material support for industries such as coatings, adhesives, packaging, and automotive. The launch of Gardolene® D fills the industry gap in chromium-free and fluorine-free passivation technology for copper foil, offering material solutions for the green upgrade of the new energy battery industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track