Baosu Machinery: Integrated Solutions for Plastic Recycling—Shredding, Sorting, Washing, and Pelletizing

Zhangjiagang Baosu Machinery Co., Ltd.Focused on the research and development as well as the manufacturing of complete systems for waste plastic recycling, the company provides services to customers in over 30 countries worldwide through high-quality customized solutions, professional real-time technology, and after-sales service. The core team of the company has more than 15 years of experience in formulating and implementing comprehensive solutions for renewable resources, with keen insight into market dynamics. The company has an independent R&D department and an experienced technical team, consisting of engineering and technical personnel who have worked in this industry for many years. Through continuous accumulation, the company has mastered application technologies in various fields of the industry, values interaction and communication with partners, and constantly pursues technological innovation.

Baosu MachineryBusiness:

01. Sorting and Washing System for Waste Plastic

02. Post-Industrial Material Plastic Pelletizing Line

03. Development of Key Equipment for Recycling Systems

04. Waste Electronic ABS PS PC Plastic Recycling Factory

05. Project Engineering Design and Installation

Baosu MachineryProvide a comprehensive waste recycling solution, relying onExpert TeamAccurate analysis of waste composition and customized recycling processes and treatment systems.Custom-madeBased on on-site customer parameters (load-bearing limits, spatial layout, water and electricity configurations, and wind direction characteristics), optimize the production line layout and simultaneously design an environmentally friendly exhaust gas and wastewater treatment system to achieve scientific control of operational costs.Precision ManufacturingThe stage utilizes advanced equipment such as laser cutting and CNC machines, with professional technicians ensuring equipment precision and operational stability. The rigorous quality inspection system certified by European standards comprehensively guarantees equipment performance and safety compliance.

— 2 —Main Products Introduction

2.1 Solid Waste (Hazardous Waste) PE/PP Plastic Crushing, Washing, Recycling, and Pelletizing Complete Equipment

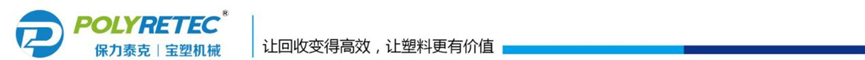

This plan focuses on the efficient recycling and reuse of various soft plastics and daily solid waste, covering the recovery of waste agricultural films, PE/PP industrial films (including PP packaging woven bags/ton bags), PE/PP packaging films, and other materials, while also accommodating the sorting and processing of complex-shaped plastics such as PP bulk bags and fishing nets. Through a high-speed friction cleaning system operating at 720 rpm, impurities are efficiently separated, precisely handling high-density materials and heavily contaminated items, ensuring the final moisture content remains stable between 3%-5%, fully compatible with the in-house pelletizing production line requirements. Relying on multi-stage sorting technology, the plan simultaneously advances the graded recycling of mixed daily waste plastics including PE/PP/ABS/PS/EVA/PVC, and implements specialized cleaning and recycling of chemical industry PP plastic packaging bags and PE hazardous waste packaging containers, forming a closed-loop system from pretreatment to recycled pellet production.

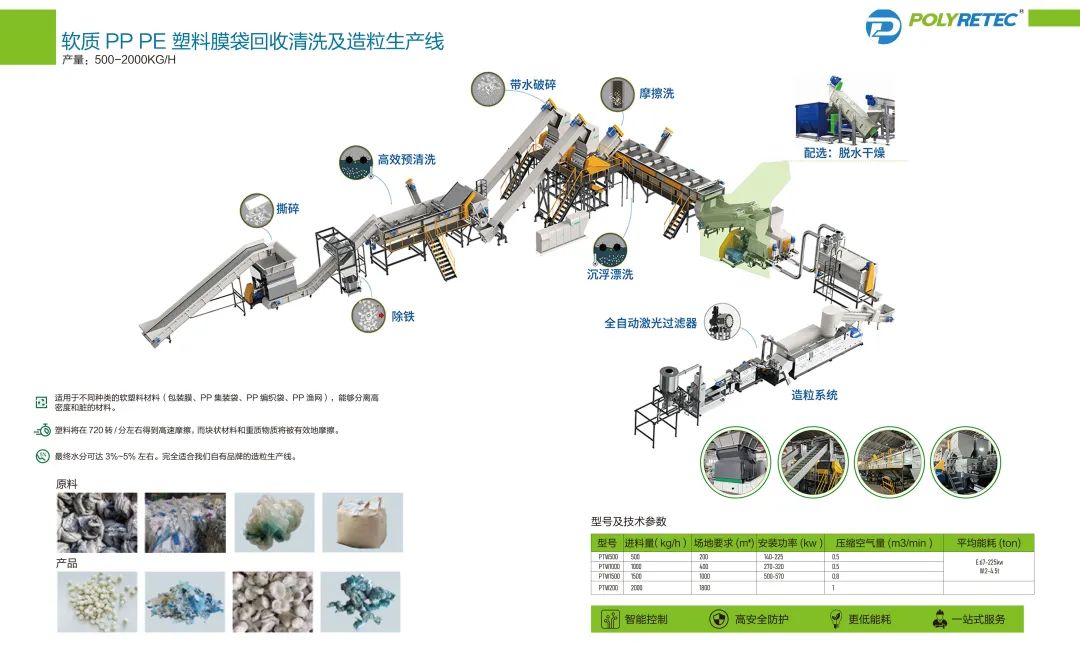

2.2 High-grade Rigid Plastic Cleaning and Recycling Production Line

2.3 PE/PP Granulation Equipment (150-1500kg/h)

Dual filtration type

Energy consumption reduced by 11-15%.

Maximum temperature reduced by 22 degrees

Capacity increased by 14%

We provide recycling and modification pelletizing equipment for PE/PP/PET/PS/PA/PVC/TPE/EVA, with experienced engineers offering comprehensive professional solutions for plastic recycling and modification. Our advanced process technologies address issues such as impurity filtration in waste plastics, pellet degradability, density, and moisture content, ensuring that customer requirements for output and quality are fully met.

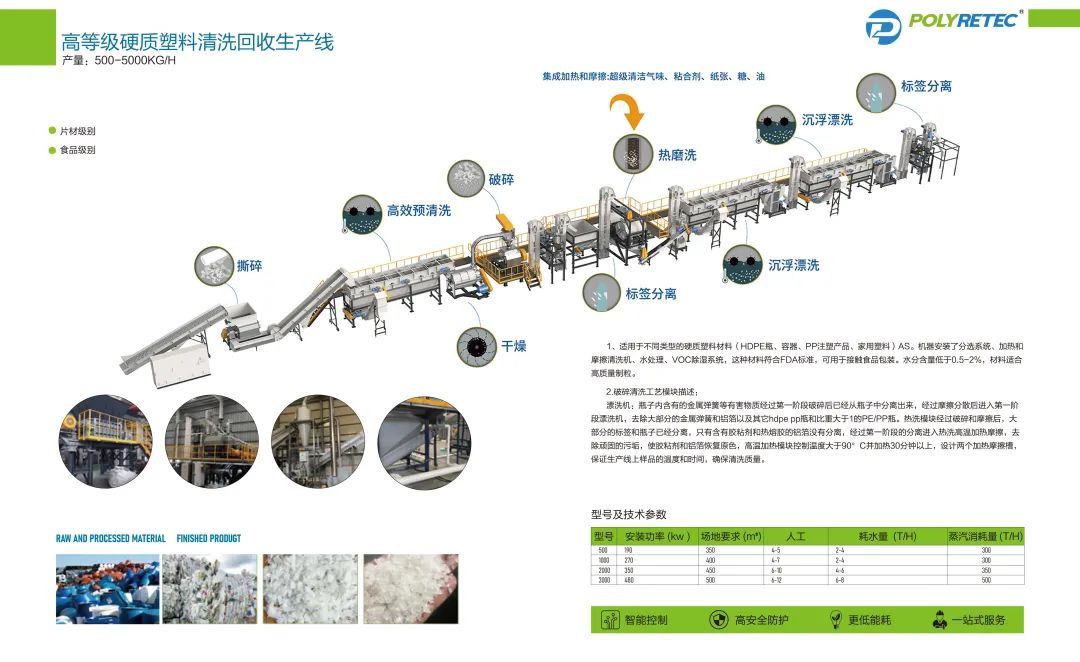

2.4 RPET recycling and washing equipment (processing capacity 300-6000kg/h)

PET plastic bottles such as mineral water bottles, beverage bottles, pesticide bottles, and other filled PET bottles recycling and processing equipment. The equipment provides automatic unpacking, automatic pre-sorting, automatic whole bottle sorting, crushing and washing, drying, color sorting, filling, and other process flows. The discharged flakes meet the 3A grade standard.

There is no running, leaking, or dripping around the equipment, which facilitates customer 7S management. The equipment is energy-efficient, labor-saving, and easy to operate; water consumption is 10-20 m³. Power consumption costs are 100-300 yuan per ton.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track