Baoli plastics acquired!

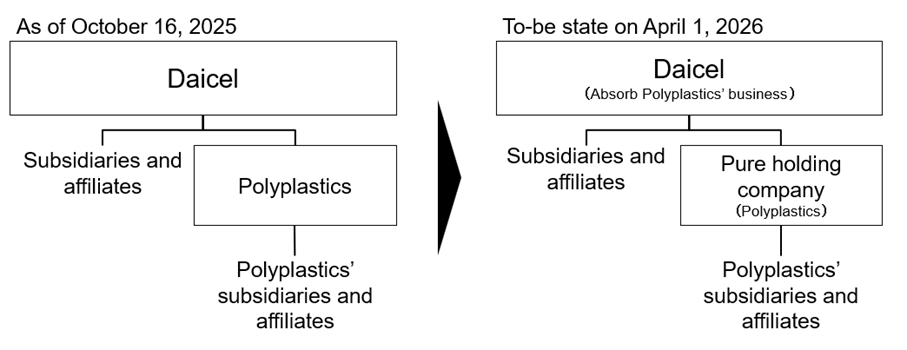

October 16, JapanPolyplasticsAnnouncement released.Daicel CorporationIt has been decided to acquire Polyplastics Co., Ltd. through an absorption-type merger effective from April 1, 2026.All business。

Specifically, Polyplastics (a Japanese company) will be split into (1) the engineering plastics business (including related ancillary businesses) and (2) the business of holding and managing shares of Polyplastics subsidiaries and affiliated companies. Daicel will fully take over the part (1) business. After the split, Polyplastics will retain its legal entity status. A change in the names of Polyplastics and its Japanese and overseas subsidiaries and affiliated companies is currently under consideration. The new company name and the specific timing of the change will be announced separately.

The purpose of this acquisition is to share Polyplastics' expertise in technical services and solutions, strengthen the synergy with Daicel's safety and materials businesses, integrate human resources to drive overall group growth, and enhance corporate functional efficiency.

Source: Polyplastics

It is reported that Polyplastics was established around 1964.Japan Daiselu CelaneseThe reasons for the joint venture are straightforward, as Celanese aims to expand into the Asian market. In 2020, Daicel acquired its then-subsidiary, Polyplastics, as a wholly-owned subsidiary to strengthen its engineering plastics business. Among them, Topas Engineering Plastics (Nantong) Co., Ltd. will commence commercial production of POM in November 2024. Polyplastics Taiwan Co., Ltd. (Kaohsiung, Taiwan) will start production at its LCP polymerization plant in February 2025. The second COC plant of TOPAS Advanced Polymers GmbH (Saxony-Anhalt, Germany) is scheduled to begin production in April 2026, all achieving steady growth.

The core technologies for several key products of Polyplastics (LCP, POM, COC, PBT) originate from Celanese, and they have also successively developed products such as PPS, LFT, high-performance resin powder, and PEK.

(1)LAPEROS®LCP

Polyplastics' LCP is based on Celanese's Vectra® technology, obtained through a technical collaboration for the fundamental polymerization process of LCP. Polyplastics has deeply developed LCP's low dielectric loss, high-frequency performance, and thin-wall molding technology to meet the demands of the Asian market, such as 5G communications and miniaturized electronic components. After Celanese divested from Polyplastics, Polyplastics formed...LAPEROS®The series of products have applied for multiple patents in areas such as LCP filling modification (e.g., glass fiber/mineral reinforcement) and hydrolysis resistance, gradually reducing complete reliance on Celanese and forming a unique competitive edge.

Currently, the total LCP production capacity of Polyplastics in Japan and Taiwan, China is about20,000 tonsHowever, Polyplastics aims to increase the overall production capacity to25,000 tons per year...to meet the global market demand for high-performance LCP materials, especially in the fields of electronics, automotive, and communications.

(2)Duracon®POM

Polyplastics' POM brandDuracon®Based on Celanese's POM technology, the process is optimized (such as improving crystallinity and enhancing wear resistance) to meet the demand for high-precision engineering plastics in the Japanese and Asian markets. This results in the development of high-flow, low-VOC copolymer formaldehyde products, which are particularly suitable for high-end applications such as electronic connectors.

Currently, Polyplastics Corporation owns four polyoxymethylene polymerization plants with a total annual supply capacity.338,000 tonsLocated in Nantong, ChinaDabao Engineering Plastics Co., Ltd. is open for business.In October 2024, the first phase of the 90,000-ton POM polymerization project successfully commenced operations in one go and is scheduled to be put into production in December. The second phase, with an estimated capacity of 60,000 tons, is expected to be put into production in 2026.

(3)TOPAS®COC

The COC from Polyplastics also comes from Celanese, with the brand beingTOPAS®In 2006, Polyplastics and Daicel Chemical, from a Celanese subsidiaryTicona Polymer CompanyThe acquisition of the cycloolefin copolymers (COC) business by Ticona GmbH led to the establishment of TOPAS Advanced Polymers GmbH. The production capacity is approximately...30,000 tons/year...has leaped to become the world's largest supplier of cyclic olefin copolymer (COC). Due to its excellent transparency, water vapor barrier properties, chemical resistance, and safety, COC is used in fields such as medical pre-filled syringes, medical diagnostic test consumables, and pharmaceutical and food packaging.

(4)DURANEX® PBT

Baoli'sDURANEX® PBTAlso originating from Celanese, Celanese is also the company that invented PBT. After subsequent localization improvements, they launched their own brand, Duranex®. Polyplastics' DURANEX® PBT features heat resistance and excellent electrical properties, and it has great compatibility with various reinforcing materials and additives. Currently, it has developed a hydrolysis-resistant series (such as 330hr, 531hs) and a flame-retardant series (such as 330nf), among others.

(5)DURAFIDE®PPS

Polyplastics' PPS is a linear PPS resin developed in collaboration with Kureha Corporation, initially branded asFORTRON® and subsequently established PPS modification factories in Japan and Malaysia. Later in 2012, it was renamed.DURAFIDE®In China, the modification and compounding of DURAFIDE® brand PPS is carried out by the factory in Nantong, China, and it has started global sales.

In recent years, Polyplastics has also launched some self-developed products, the most representative of which are long fiber reinforced thermoplastic (LFT), high-performance resin powder, and polyether ketone (PEK).

(6)Plastron®LFT

Polyplastics launchedPlastron® Series Long Fiber Reinforced Thermoplastics (LFT)Using a range of fiber-reinforced materials such as glass, carbon, and cellulose, including PP, PA6, PA66, PA9T, PA12, and PAMXD6, LFT can be used in industrial pumps, pipe joints, automotive functional parts, etc., making it a very important lightweight composite material. Additionally, Polyplastics previously announced that it is developing LFT materials with recycled PP resin substrates to further reduce the carbon footprint.

(7)DURAST® Powder

Baoli PlasticsDURAST® Powder High-Performance Resin PowderSeries, mainly resin powders of LCP, PPS, POM, and PBT, mainly used for3D printingThis powder can achieve mass production of complex shapes and high-precision components. Moreover, it can also be used to manufacture uniform porous structure filter materials and serve as an additive in thermosetting resins, coatings, and lubricants.

Powderization of high-performance resins has long been a challenging technical barrier for many companies. Traditional pulverization methods can easily lead to issues such as particle entanglement and agglomeration, as well as a sharp decline in flowability. However, Polyplastics has developed customized processes tailored to the thermal characteristics and mechanical properties of different resins, successfully achieving uniform powderization of various high-performance resins. The average particle size of DURAST® LCP powder can be precisely controlled between 1 and 100 μm, while the particle sizes of PBT and POM powders remain stable in the 20 to 100 μm range. Moreover, all categories feature a narrow particle size distribution and regular shapes.

(8)DURAST® PEK

In 2024, Polyplastics launched a polyether ketone called Sarpek PEK, primarily used for metal replacement and suitable for injection molding applications that require extremely high heat resistance without the need for post-curing. According to Polyplastics, this is a more advanced material than polyether ether ketone (PEEK), featuring a high crystallization rate and excellent molding efficiency. Its heat resistance and mechanical strength make it suitable for replacing metal in harsh environments where other crystalline super engineering plastics might fail. Sarpek PEK has a melting point of 370°C and a glass transition temperature of 155°C. It is available in an unreinforced grade as well as a 30% glass fiber-reinforced grade and a 30% carbon fiber-reinforced grade.

Polyplastics achieved a record profit in the last fiscal year with these material combination products. As a technology-driven engineering plastics company, Polyplastics has always had strong R&D capabilities, continuously reducing its reliance on Celanese. Other Japanese companies such as Toray, Asahi Kasei, and Mitsubishi have also mostly introduced technologies from the United States and have ultimately achieved surpassing them. However, with the rise of Chinese domestic polymer companies, the era of post-modified engineering plastics may pose a significant challenge to traditional engineering plastics giants.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track