Automakers Adopt New Identities

Against the backdrop of the deepening implementation of the "dual carbon" strategy, new energy logistics vehicles have not only become powerful tools for logistics enterprises to reduce costs and increase efficiency, but have also emerged as a core force driving the green transformation of the transportation industry. However, behind the industry boom, traditional OEMs are deeply mired in the dilemma of "selling vehicles"—as previously discussed by EV Resources in the article "The Simplest 'Selling Cars' Has Become the Hardest Road to Take?!".The once simple model of "production equals sales" has long become obsolete. The intensified homogenized market competition has triggered frequent price wars, continuously compressing the profit margins of single vehicle sales to a low level, while also failing to meet logistics companies' integrated demands for "vehicles + services + scenarios." This triple pressure of "difficulty in selling vehicles, thin profits, and mismatched demand" forces manufacturers to accelerate their shift away from the traditional framework of "making good vehicles and selling good vehicles," proactively transforming into comprehensive service providers.

Since last year, many OEMs have been eager to launch their own ecosystem brands, and it is an inevitable trend for new energy logistics vehicle manufacturers to transform into comprehensive service providers.From FAW Jiefang launching the "Jiefang Green Power" aftermarket brand, to Changan Kaicheng partnering with CATL, JD.com, and Huawei to build an intelligent logistics ecosystem, and to JAC Motors' large-scale vehicle delivery cooperation with KuaYue Express, OEMs are now participating in market competition with entirely new identities.

New Role in the Ecosystem Layout of OEMs

Facing industry transformation, OEMs are actively seeking to shift their roles, transitioning from traditional vehicle manufacturers to comprehensive solution providers.

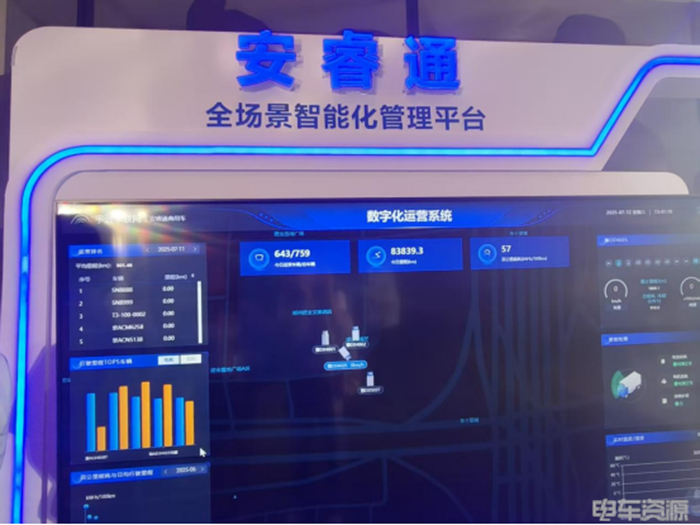

First, achieve deep operational services through a self-owned transportation capacity platform.SAIC Maxus has established a digital urban distribution service platform with a scale of nearly 10,000 units, utilizing "Lingju Transportation Capacity" to achieve intelligent capacity scheduling. Foton Motor, through "Foton Zhicheng," has launched a comprehensive solution for new energy logistics vehicles, enhancing vehicle operation efficiency. Geely's "Green Smart Link" under Farizon Auto relies on the "Smart Vehicle Management" platform, integrating intelligent driving assistance and risk warning functions to comprehensively improve transportation safety and economy. Jiangling Motors has also established "Jiangling Lexing," exploring scenario-based operations for new energy commercial vehicles. Dongfeng Motor, through "Dongfeng Blue Card," is deploying new energy logistics capacity to provide customers with green, efficient, and intelligent transportation services.

Secondly, in building a closed-loop service system for the aftermarket, OEMs are extending from single vehicle sales to full value chain services.FAW Jiefang not only leverages the "Jiefang Era" to expand transportation capacity operations, but has also launched the "Jiefang Green Power" aftermarket brand, focusing on remanufacturing, used vehicle refurbishment, and full life-cycle services, continuously extending the industry value chain. This initiative not only enhances user loyalty and service revenue, but also drives the company's transformation from traditional manufacturing to an integrated "manufacturing + service" model.

Finally, strengthen differentiated advantages through technological collaboration and ecosystem cooperation.China National Heavy Duty Truck Group (CNHTC) has partnered with “Weichai Zhike” to launch intelligent logistics solutions; Qingling Motors has joined hands with “Longtong Leasing” to explore new leasing models for high-end new energy light trucks; while New Gonow Automobile is experimenting with intelligent urban distribution capacity scheduling through the “Biying Huodi” platform. These enterprises are no longer confined to traditional manufacturing. Instead, they are using operations as a link to integrate resources, export standards, and build ecosystems.

It can be seen that automakers are systematically deploying the entire industry chain—from vehicle R&D and energy management to mobility services and used car recycling—through operating subsidiaries or deep cooperation platforms. They are no longer just selling cars, but are continuously engaging users and creating long-term value through integrated solutions of “vehicle + service + data.”

New Challenges for Operators

The multi-dimensional transformation of OEMs has exerted a strong impact on the traditional operational ecosystem, with all aspects facing unprecedented pressure for identity reconstruction.In the traditional model, the simple buy-sell relationship between operators and OEMs has been diminished. OEMs are penetrating the operations side through vertical integration, directly participating in the competition of the transportation capacity market and squeezing the survival space of operators. Moreover, OEMs are now directly cooperating with large operation companies like Didi and logistics enterprises, further encroaching on the survival space of small and medium-sized operators.

Operators urgently need to reposition their value by specializing and deeply cultivating segmented markets. In vertical fields such as last-mile urban delivery and cold chain logistics, operators’ scenario-based operational experience and accumulated customer resources are irreplaceable.By focusing on specific scenarios, operators can form a differentiated competitive advantage and create a complementary rather than directly competitive relationship with OEMs.

On the other hand, regional operators can rely on their ability to integrate localized resources to build core competitiveness in local markets.Regional operators can leverage localized charging networks, maintenance services, and other resources to complement the nationwide layout of OEMs. For example, in third- and fourth-tier cities and county-level markets, the local network advantages of operators can fill the service coverage gaps left by OEMs. By jointly building regional service networks with OEMs, they can achieve optimized resource allocation and shared benefits.

Tram resources survey found that the mainstream operators are currently transforming from simple vehicle purchasers to partners in co-developing products with OEMs.However, a large number of small and medium-sized operators are facing survival difficulties due to compressed profit margins and challenges in after-sales management.However, at the same time,A mechanism for capital cooperation and risk-sharing is gradually taking shape, with OEMs and operators strengthening strategic collaboration through capital ties, jointly investing in the development of exclusive models and logistics systems, sharing profits and risks.This deep binding relationship makes both parties more focused on long-term value rather than short-term transactions, promoting stability and efficiency improvements in the supply chain.

It is worth noting that some OEMs, such as Yutong, have not chosen to directly participate in operations. Instead, they are helping customers connect with cargo sources and optimize vehicle-cargo matching, growing together with operators. This approach of "empowering rather than replacing" offers new possibilities for building a healthy and sustainable industry ecosystem.

From the exploration of intelligent transportation capacity for remote new energy commercial vehicles to the full-cycle layout of "Jiefang Green Movement," OEMs have completely broken away from the traditional framework of single vehicle manufacturing. The practice of their new identity has reshaped the industry's value logic through technology integration and data empowerment.Currently, automakers are actively expanding their operational businesses, not only as a key measure to broaden their own channel systems, but also to directly respond to the increasingly diverse needs of users in areas such as vehicle usage, management, energy, and the aftermarket. This aims to build an integrated "vehicle, energy, and network" service capability.

It is foreseeable that in the future, more OEMs will create their own ecosystem platforms to collaborate with charging enterprises, logistics companies, and technology companies to jointly build a more efficient new energy logistics operation ecosystem. In this process, the traditional operator model will not be eliminated, but will move towards centralization. Large operators will rely on their financial resources, service networks, and customer capabilities to transform into regional comprehensive service partners, taking on functions such as offline operations, localized services, and penetration into niche markets that OEMs find difficult to cover comprehensively.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track