Asahi Kasei to Launch PFAS-Free Polyamide and CFRP Recycling Technology

On September 3rd, Asahi Kasei Corporation of Japan will showcase its latest innovations in PFAS-free polyamide (PA) and continuous carbon fiber recycling technology at the plastics and rubber trade fair K 2025. The company will also present its diverse material solutions aimed at automotive applications, connectivity, and lightweighting.

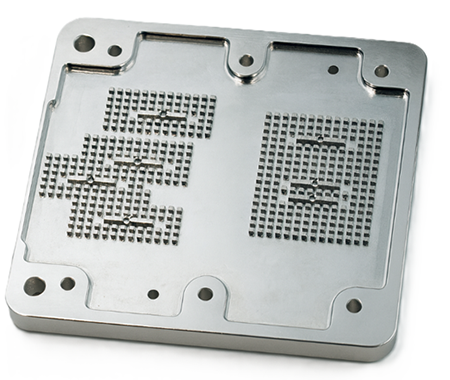

Image source: Asahi Kasei

Asahi Kasei has developed a groundbreaking recycling technology that can recover continuous carbon fibers from CFRP (carbon fiber reinforced plastic) pressure vessels used in automobiles. This process utilizes electrolytic sulfuric acid to completely decompose the resin matrix while preserving the original strength and continuous structure of the carbon fibers. Unlike traditional recycling methods that result in short fibers, this technology can permanently recover high-quality, cost-effective continuous carbon fibers from CFRP pressure vessels. At K 2025, Asahi Kasei will showcase over 200 meters of regenerated continuous carbon fiber.

Asahi Kasei will also showcase PA and SEBS (hydrogenated styrenic thermoplastic elastomer) composites using bio-based biodegradable cellulose nanofibers (CNF). This material is made from cotton linter and features high heat resistance and network-forming capability. CNF-reinforced polyamide exhibits reduced viscosity during mixing, making it highly suitable for 3D printing applications, with easy printability, precise dimensions, smooth appearance, and excellent mechanical properties. CNF-reinforced SEBS offers unique softness that can be adjusted by altering the internal structure of molded products. Additionally, it has extremely low warpage and shrinkage rates, as well as good hydrolysis resistance. These characteristics make the material suitable for various applications, such as jigs and tools or prosthetics and orthotics.

To meet the growing market demand for PFAS-free materials, Asahi Kasei is developing a PFAS-free low-friction LEONA™ PA, which will be launched for the first time in Europe. According to internal evaluations, this material has the same low-friction performance as fluororesin and is suitable for sliding applications in various industries such as automotive, robotic components, office equipment components, and sporting goods.

The automotive manufacturing industry is increasingly focusing on weight reduction and design improvement. At the K 2025 exhibition, Asahi Kasei will showcase a variety of technologies to address the most pressing issues faced by automakers. AZP™ transparent polymer exhibits minimal birefringence and is lightweight. It overcomes the challenges that traditional transparent polymers encounter in polarized light applications—such as virtual reality and augmented reality devices, as well as automotive head-up displays (HUD)—while maintaining excellent processability, making it suitable for large-scale production of injection-molded optical components. The company will present an interactive automotive demonstration at K 2025 to showcase how AZP™ enables the next generation of HUDs.

Image source: Asahi Kasei

The surface layer, foam layer, and core layer of traditional car dashboards, door panels, armrests, or center consoles use different materials and production techniques. Asahi Kasei's SEBS material is suitable for the skin and foam layers and can be used in a single-step injection molding process with a core backing. The layers have strong chemical bonding without the need for additional adhesive layers. SEBS helps reduce the total amount of material, simplify the manufacturing process, and improve the recyclability of interior components.

Image source: Asahi Kasei

Another solution from Asahi Kasei that simplifies the production processes for automotive OEMs is SunForce™ mPPE (modified polyphenylene ether) bead foam. This material is highly suitable for mass production of thin-walled, complex-shaped parts that require low tolerances, high thermal stability, or UL94 V-0 flame retardancy. These characteristics make SunForce™ an ideal choice for thermal management solutions in electronic devices, lithium-ion battery transport trays, insulation components for HVAC equipment, and foam cores for FRP (fiber-reinforced plastic) composite parts.

Image source: Asahi Kasei

With the increasing application of radar in various industries, the pressure to reduce material, production costs, and weight is also growing. Slotted waveguide array antennas used in automotive millimeter-wave radar are typically made of metal, requiring expensive and time-consuming milling processes. Asahi Kasei's XYRON™ mPPE has mature wet plating performance, eliminating the need for milling processes and enabling mass production of resin antenna components through injection molding, thereby reducing costs and enhancing scalability.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track