Asahi kasei duraflex™: Low Viscosity Curing Agent Enhances Thermal Management Material Performance

Thermal issues, industry consensus

The rapid development of new energy vehicles, 5G communication devices, and AI servers has driven the miniaturization and high integration of electronic components.The resulting heat generation issue has become a core challenge restricting performance and lifespan.

Especially inGap filler thermal materialThe demand for high thermal conductivity in applications continues to increase, but the contradiction of "high filler leads to high viscosity and processing difficulties" always exists.How to maintain good fluidity while improving thermal conductivity.It has become a key issue in the thermal material industry.

01Core Advantages

Meeting multiple requirements of thermal conductivity, process compatibility, stability and reliability, and global compliance.

1High thermal conductivity efficiency"—— Relies on high loading of thermally conductive fillers, but can lead to an increase in system viscosity."

2Process Compatibility- Narrow components and complex structures place higher demands on material flowability.

3Long-term reliabilityThe material needs to have good flexibility to withstand vibration and thermal cycling.

Industry competition is gradually shifting from "Single thermal conductivity"towards"Comprehensive AdaptabilityEvolution.

02Asahi Kasei Solutions

DynaDrive™Low-viscosity HDI-based polyisocyanate curing agentWith its low viscosity technology, it provides a new solution for thermal materials:

HDI (Hexamethylene Diisocyanate) ==

[Polyisocyanurate Deron™]

Low viscosity grade (Viscosity representative value @25℃)

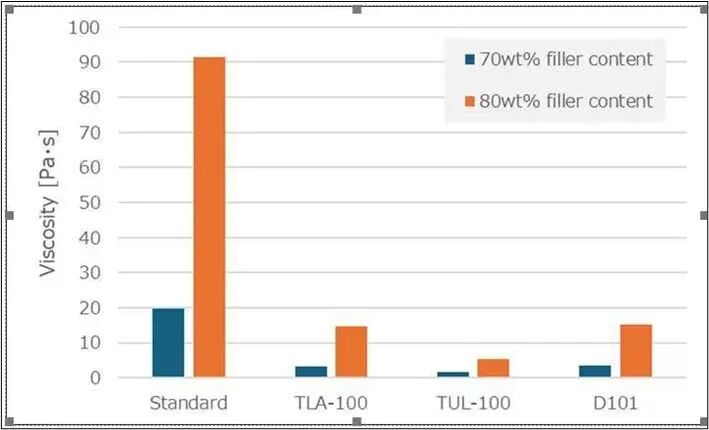

· Donide™ TLA-100 (500mPa·s)

·Duonade™ TUL-100 (300mPa·s)

- Donide™ D101 (500 mPa·s)

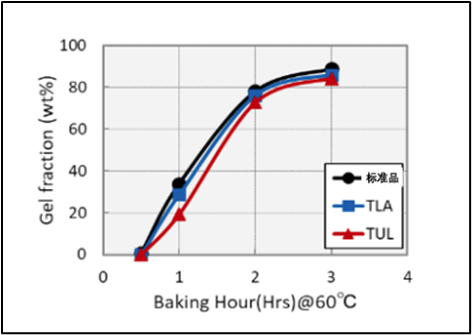

Low viscosity + High curability

Maintain curing performanceMeanwhile, significantly enhance under appropriate conditions. Liquidity。

Chart: Viscosity Comparison When Adding Thermal Interface Material

Figure: Curing Properties of Low Viscosity Grades (Evaluated in Combination with Commercially Available Acrylic Polyols)

Rich product lineup

Viscosity range coverage300–500 mPa·sMeeting different formulation needs.

03Application value

- New Energy Vehicles:Improving the cooling of power batteries and electronic control modules to enhance safety and lifespan.

・ 5G Communication:The high-frequency operation of base stations and antenna equipment ensures long-term stability.

・ AI Server:The thermal management requirements of high-performance computing chips ensure the efficient operation of data centers.

The competition in thermal materials is entering a new stage: it not only needs to conduct heat, but alsoBalancing craftsmanship, reliability, and compliance.。

Asahi Kasei's DURANEX™ series, withLow viscosityTo help overcome the dilemma of "high filler = high viscosity," it provides industry clients with options that combine performance and processability.

In the evolution of heat dissipation technology, material selection is crucial.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics