Are electric cars as reliable as gasoline cars?

History always advances in a spiral and progresses in a back-and-forth manner.

In the past five years, China's automotive industry has made significant progress in "changing lanes to overtake" through new energy and intelligent transformation. However, a tragic accident not only ended the lives of three young girls but also slowed down the progress of intelligent driving. Frequent incidents of new energy vehicles catching fire have not only destroyed the assets of car owners but also negatively impacted consumers' perception of electric vehicles as a whole.

How to further advance under the high baseline condition where the penetration rate of new energy exceeds half? How to extend consumers' high trust in fuel vehicles to electric cars?

"When you feel confused, look for answers in history." During the era of fuel vehicles, German cars were the most favored by Chinese consumers for their safety and reliability. Can the durability and safety, which encapsulate the engineer's mindset and a century's worth of industry accumulation, allow electric vehicles to be on par with fuel vehicles?

As a leader in joint venture automobiles, FAW-Volkswagen has given a definite answer: Yes!

The premise is whether car companies can, like they have done with gasoline cars over the past hundred years, carefully refine the quality of cars to improve reliability, durability, and safety.

FAW-Volkswagen used a "Quality Journey" at the Changchun base to explain how enterprises should "cultivate internal skills" behind the high reliability and high safety of new energy vehicles.

Breaking the security and trust crisis and reshaping the industry's value coordinates has never been an empty slogan. It is built upon the sweat of thousands of people and countless precise operations as delicate as a strand of hair.

01Quality and Safety First

"Finally understand why FAW-Volkswagen has been the top in joint venture sales for so many years," a media friend remarked halfway through the quality journey, "such solid effort put in indeed makes people trust more, and they will vote with their feet."

In mid-July, FAW-Volkswagen launched a media open event for Quality and Safety Month.

Many years ago, I also participated in FAW-Volkswagen's quality tour and learned about the strict requirements for processing precision and paintwork in fuel vehicles at that time. Now that the automotive industry has entered the era of new energy and intelligent technology, what new connotations have been given to quality? Can electric vehicles be made as reliable as fuel vehicles?

What is gratifying is that FAW-Volkswagen remains the same FAW-Volkswagen, consistently upholding safety, durability, and reliability as the core values.

When some car brands "shout safety for marketing," FAW-Volkswagen continues to move forward with determination, "putting safety into practice."

Some manufacturers also claim they use 2200Mpa ultra-high strength steel, comparable to submarine/carrier-grade steel. How is your hot-formed steel application different? In response to this question, the FAW-Volkswagen engineer provided a patient and detailed explanation.

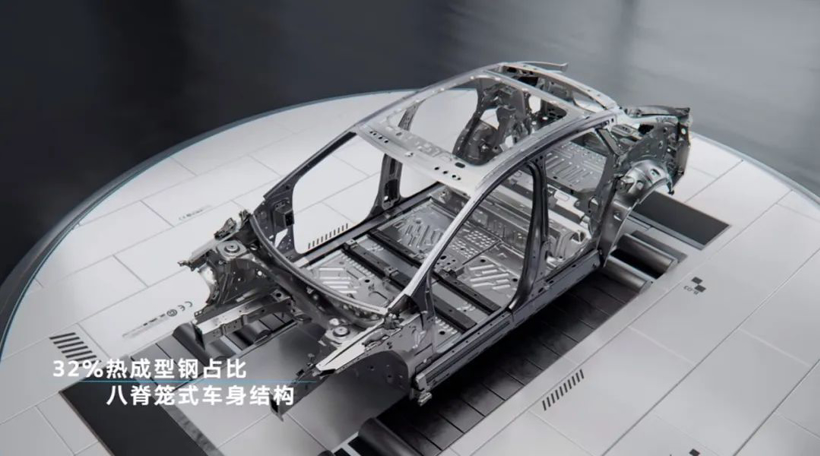

Diagram | The body structure schematic of ID.7 VIZZION, with hot-formed steel accounting for as much as 32%.

"These numbers are quite impressive, but the passive safety of the car body is not just about the strength of the materials; it also depends on the structure of the car body, the amount of materials used, and their distribution in the car body, among other factors." FAW-Volkswagen does not overly promote the 2150MPa strength figure of hot-formed steel but instead places greater emphasis on the amount used and its distribution. FAW-Volkswagen's high-strength steel usage proportion reaches 81%, with hot-formed steel used in key parts such as the A-pillar, B-pillar, and body crossbeam. In the ID.7 VIZZION, hot-formed steel accounts for more than 30%.

If we use a metaphorical conversion, 2150 MPa is equivalent to four elephants standing on an area the size of a fingernail. Some manufacturers might engage in a "numbers arms race" in certain areas, pushing the strength data up to 2200 MPa, but they lack the confidence in terms of usage proportion and distribution that FAW-Volkswagen has. Therefore, who truly has the "iron-clad body" is self-evident.

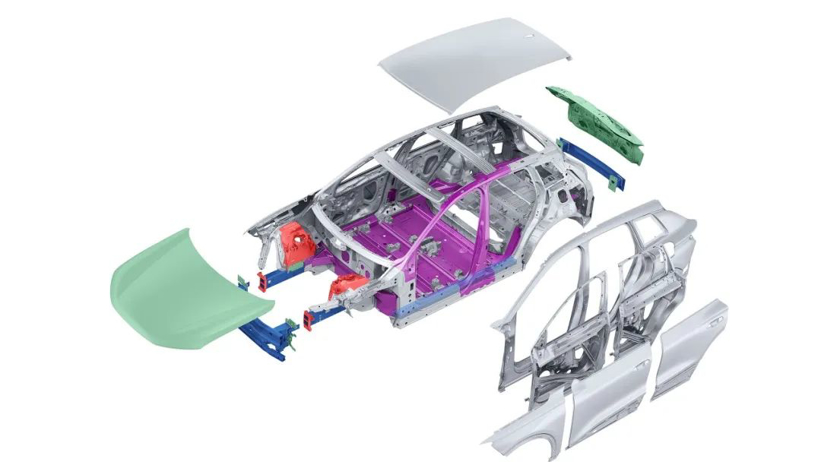

Diagram | Latest Q6L e-tron body structure schematic, with the purple section using 2150 MPa hot-formed steel.

If the strength of the vehicle's steel is related to passive safety, then FAW-Volkswagen has not relaxed its pursuit in other safety dimensions and has expanded the concept of "safety" to be all-encompassing.

In the "Golden Nose Laboratory," engineers need to conduct blind tests to identify interior emissions, ensuring that the benzene content is below the national standard of 50%. This is the "health safety" of the in-car environment. The starting point of the L2 driving assistance capability without images is not a flashy embellishment, but rather an extension of value with "greater safety and convenience" at its core, closely tied to the "essence of travel serving people." This is the "active safety" of intelligence. The development of battery non-thermal diffusion technology has established a strict defense line to ensure that power batteries do not catch fire, which is the most sensitive "battery safety" in new energy.

FAW-Volkswagen has also endowed the quality and safety of its cars with three levels:

Firstly, user safety, adhering to German quality, creating a new intelligent electric vehicle, and providing a new experience for pleasant travel.

Second, ensure corporate security by adhering to open cooperation, creating a new joint venture model, and providing comprehensive protection across time cycles.

Thirdly, ensure industry safety, firmly lead by example, drive the advancement of the entire industry chain, and promote the establishment of a transparent consumer environment.

From this, it can be seen that the quality and safety of automobiles have been expanded by FAW-Volkswagen from the consumer level to the industrial chain level, extending from user care to industry care. They have truly achieved the combination of a century-old German quality heritage with China's leading cutting-edge technology and craftsmanship.

02"Do a little more than others"

In the entire journey of quality, the most impressive aspect of FAW-Volkswagen is not a single highlight, but the shared characteristic of overall quality—habitually setting rigorous standards beyond expectations, "always doing a bit more than others, always exceeding industry requirements."

"Our equipment costs over 20 million yuan. As you can see, it is as tall as a one-story building, but there is actually another level both above and below, making it equivalent to the height of a three-story building," an FAW-Volkswagen engineer explained to us during a tour of the battery safety laboratory, introducing the equipment that simulates the overload resistance capability of power batteries.

The current national standard only requires a single axial overload simulation, but FAW-Volkswagen's expensive equipment conducts six degrees of freedom testing. In addition to three-dimensional movements in up, down, left, right, front, and back directions, it can also create curvilinear and circular motions. This allows the battery pack to undergo charging and discharging states amidst intense vibrations, simulating the overload conditions the battery may endure during regular driving, thereby ensuring the intensity of battery testing.

"This is the true guarantee of automotive-grade quality!" exclaimed a visitor. "In comparison, automotive-grade tissue boxes are much weaker."

Not only is "the equipment better than others," but FAW-Volkswagen also "tests more than others" and has "stricter standards than others."

"Strict self-discipline" was originally a personal requirement, but FAW-Volkswagen has formed an industry standard under many of these excessive criteria:

FAW-Volkswagen's welding count can reach up to 13,000 densely packed points, which is more than a 50% improvement compared to vehicles in the same class. This results in the formation of a complete force transmission network during a collision, preventing excessive local deformation.

The average welding adhesive usage per vehicle is 100 meters, which is 40% higher than the industry standard. This not only strengthens the body rigidity but also creates a barrier to block noise and prevent rust.

When the national standard requires a 5-minute time limit for thermal runaway warning of power batteries, FAW-Volkswagen has improved this indicator to within 10 seconds, thus providing customers with valuable emergency time in the event of an accident.

Conducted four rounds of crash tests for a single model, with more than 30 crash test vehicles and nearly 100 crash tests, which is more than twice the number of tests conducted by emerging brands.

……

When we read fables, we often hear about the "math story" where 1.1 is only slightly greater than 1, and 0.9 is only slightly less than 1. However, the product of ten 1.1s is approximately 2.59, and the product of ten 0.9s is approximately 0.35. A significant difference has already emerged between the two.

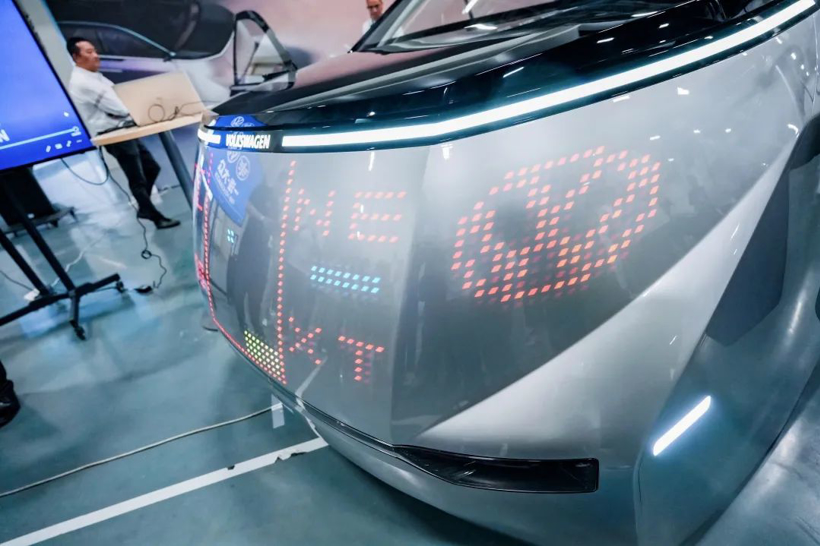

Photo | Safety Month Open Day event====

In the field of automobiles, which are considered the crown jewels of contemporary manufacturing, as intricate and complex systems, automobiles are far more than just the simple multiplication of ten components. If every subsystem and even every component exceeds the standard requirements, how many times higher would the overall reliability and safety be compared to conventional standards? Conversely, if every component is "cutting corners a little," how much higher would the overall quality failure rate be compared to conventional standards?

In FAW-Volkswagen's quality self-requirements, we see that this leading company strives to move towards "1.1" or even "1.5" and "2.0", so the overall vehicle quality standard is beyond question.

03Extreme testing experiments > extreme spec sheet parameters

If the benefit that consumer electronics brings to the automotive industry lies in enhancing the speed of evolution and the richness of functional ecosystems, then the downside is the dilution of the automotive industry's traditional rigorous testing protocols.

Moreover, consumers of electronic devices are accustomed to using "benchmark scores" and other paper specifications to evaluate products. If this approach is brought into the automotive industry, it can lead to numerous accidents.

Fortunately, there are car manufacturers like FAW-Volkswagen that would rather not rely on extreme on-paper specifications to gain attention and publicity. Instead, they choose to "self-torture" through rigorous testing processes to ensure that every car delivered to customers is sufficiently reliable and safe.

FAW-Volkswagen has set much stricter requirements for power battery safety than the national standards mentioned earlier, so how can such superior performance be achieved? This relies on testing and inspection that are "much more challenging than national standards."

In the thermal runaway warning performance test, the national standard only requires one round of testing, while FAW-Volkswagen conducts six rounds. After all, safety is no small matter; testing can only be intensified, not discounted. Each test challenges the limits to ensure that after the vehicle is delivered, there are no mishaps in the user's daily driving scenarios.

For the entire battery pack, using a 79kWh standard lithium iron phosphate battery module as an example, it undergoes testing exceeding 190 items, whereas international standards only have 18 items. Additionally, FAW-Volkswagen subjects the battery pack to extreme conditions such as a 5-meter vertical drop and immersion in a -40℃ ice chamber for cyclic charging and discharging.

Regarding the overall testing of new energy vehicles, the national standard requires a total of 53 tests for new energy vehicle components, while FAW-Volkswagen mandates 436 tests. Some of the most stringent test requirements can be ten times that of the national standard. "Putting in ten times the effort in the laboratory may result in a tenfold or even greater improvement in reliability during daily use by customers." The audience was astounded.

Image | The safety of power batteries is related to life safety! It must adhere to the highest standards and strictest requirements.

Crash testing is the "star project" in automotive testing. FAW-Volkswagen not only includes national standards, China Automotive Technology and Research Center, and China Insurance Automotive Safety Index tests in their testing scope but also proposes its own unique crash test projects.

From the quality journey years ago, we have already known that FAW-Volkswagen conducts comprehensive tests on vehicles leaving the factory, including rain, sun exposure, and bumpy road conditions. However, this time we truly felt how the quantitative figures demonstrate the "profound inner strength" that contributes to the reliability of new energy vehicles.

Afraid that the charging port and other parts of new energy vehicles might become disabled after getting wet? FAW-Volkswagen's rain test achieves a 100% detection rate, reaching a high industry standard. The rain test lasts for 6 minutes, simulating continuous spraying equivalent to a heavy rainstorm for 24 hours, with each nozzle spraying at a pressure of up to 2.5 bar...

Concerned that new energy vehicles may not be able to withstand extreme temperatures? FAW-Volkswagen completes over 7 million kilometers of real vehicle testing before delivery, equivalent to approximately 175 laps around the equator. Test stations are set up in conditions as hot as Turpan in summer and as cold as Heihe in winter.

Worried about whether the chassis of new energy vehicles can withstand the strain of sharp turns? FAW-Volkswagen has built Asia's largest and most comprehensive FAW-Volkswagen Automotive Proving Ground, which includes a 9.9-kilometer high-speed circular track with a 48.8-degree banking. Vehicles undergo tests on 58 sets of curves and 28 types of special road conditions, with test drivers running for over eight months, accumulating a total of 100,000 kilometers.

Traditional automakers like FAW-Volkswagen seem to be "slow" in the initial stages of new energy vehicles because they have to undergo such rigorous testing. Why do traditional automakers like FAW-Volkswagen seem to have "fewer" features in their new energy vehicles initially? Because without going through so many processes, they cannot easily be put on the road.

Nowadays, with numerous technologies and features having been thoroughly tested and validated, it can be predicted that the joint venture new energy vehicles led by FAW-Volkswagen will usher in an upward opportunity.

Focusing on extreme parameters on paper can allow a car company to progress quickly for a time; extreme quality testing can enable a car company to go far in the long term. FAW-Volkswagen has unhesitatingly chosen the latter, which embodies both heritage and determination, backed by a customer-centered long-term vision and altruism.

Precipitation? Mission? What is the path for the Chinese automotive industry to break through to the next stage? FAW-Volkswagen uses a journey of quality to see the big picture from the small details. In the fog and haze, the lights are already flickering, guiding us forward.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track