Aquacer 1062 new high-efficiency temporary rust inhibiting wax emulsion solution

During storage and transportation, exposed metal surfaces often face severe challenges: the salt in seawater and sea breeze, as well as condensation caused by extreme temperature changes, can easily lead to corrosion. Therefore, there is an urgent need for an efficient temporary anti-rust solution, and the anti-rust layer should be easily removable from the metal surface during subsequent processing.

AQUACER 1062 is a new wax additive launched by BYK Chemical, designed specifically for temporary rust protection while meeting extremely high gloss requirements. With excellent wettability and film-forming properties, it forms a protective layer on metal surfaces, effectively blocking moisture contact. This product does not adversely affect the gloss of the surface, making it suitable for black metal surfaces as well. Additionally, AQUACER 1062 is very easy to use and can be applied to metal surfaces through various methods such as dip coating, spray coating, or spin coating, and can be easily removed under alkaline conditions.

Technical Data

Ethylene-acrylic acid (EAA) copolymer wax emulsion

Non-volatile matter (60 minutes, 125 ℃): 22%

Carrier: Water

Melting point: 95°C

pH value: 9

Advantage

Excellent corrosion protection

Good metal adhesion

Exhibits excellent wettability and film-forming properties on metal surfaces.

Easy to apply in construction

Suitable for a wide range of metal surfaces (such as steel, nickel, aluminum, non-ferrous metals), and also suitable for ferrous metals.

It can be mixed with water in any proportion under conditions where the pH value is above 8.5.

Adjusting viscosity can regulate the dry film thickness.

Under alkaline conditions, it can be easily removed.

It can be used in conjunction with silicates or other resins, or used alone.

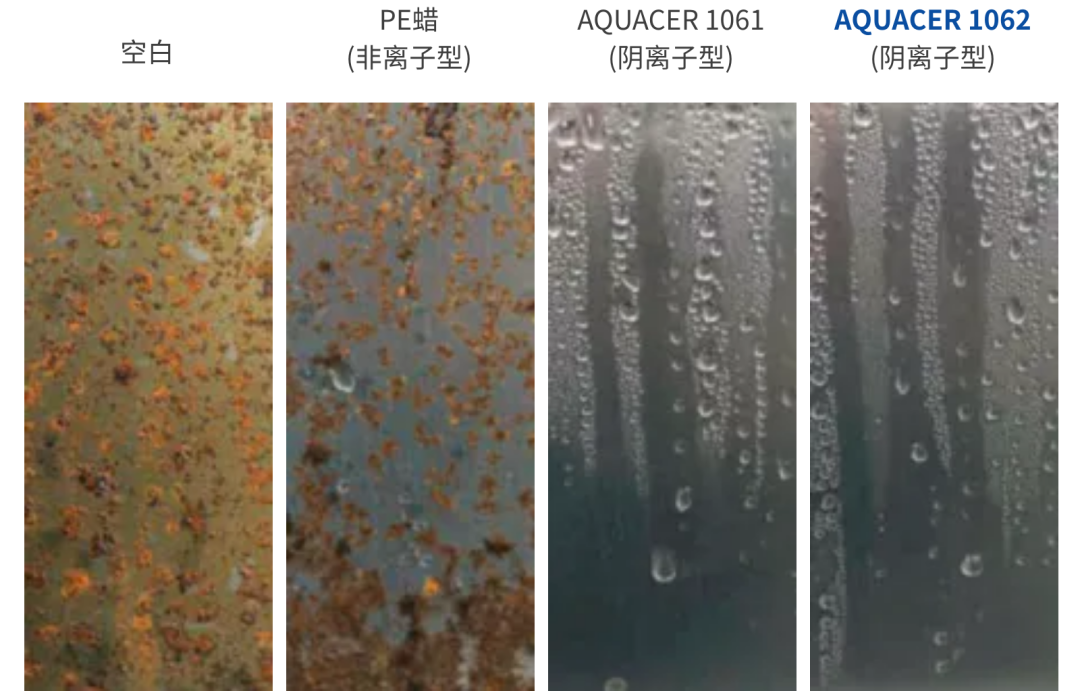

Condensate Water Test

Add AQUACER 1062.

Exhibits excellent anti-rust protection performance after 5 weeks.

Test substrateQ-PANEL R-46 (Matte, Rolled Steel)

Additive dosageDilute wax emulsion to a solid content of 10%.

Test MethodCondensation test (DIN EN ISO 6270-2), the film is dried at 80°C for 3 minutes (dry film thickness: 1~5 microns), photos taken after 5 weeks.

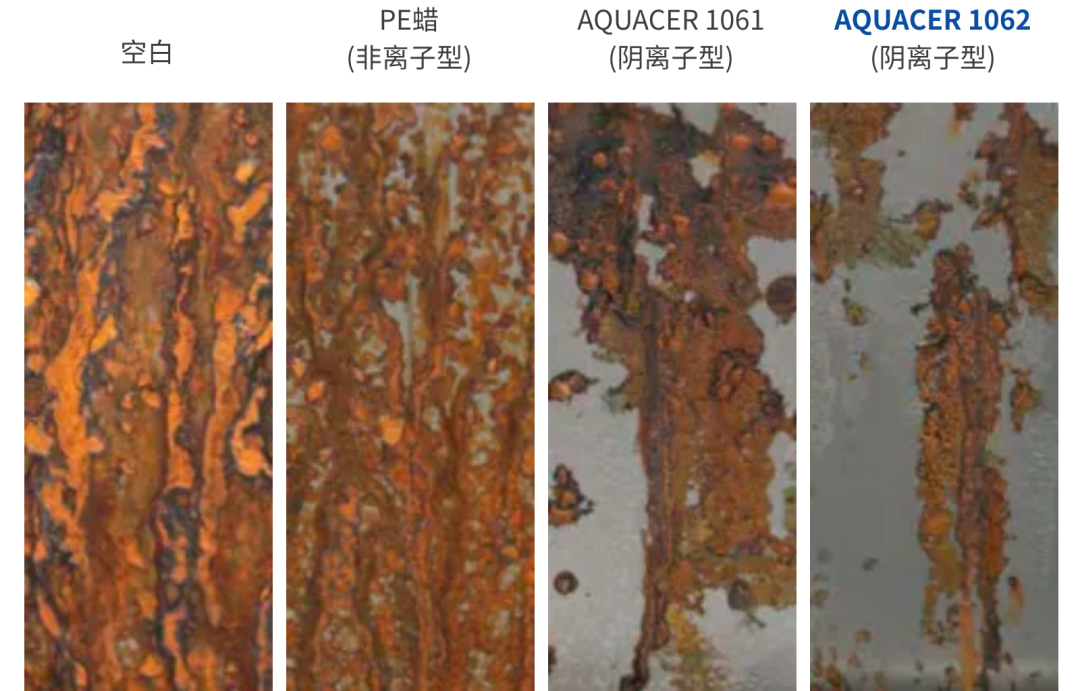

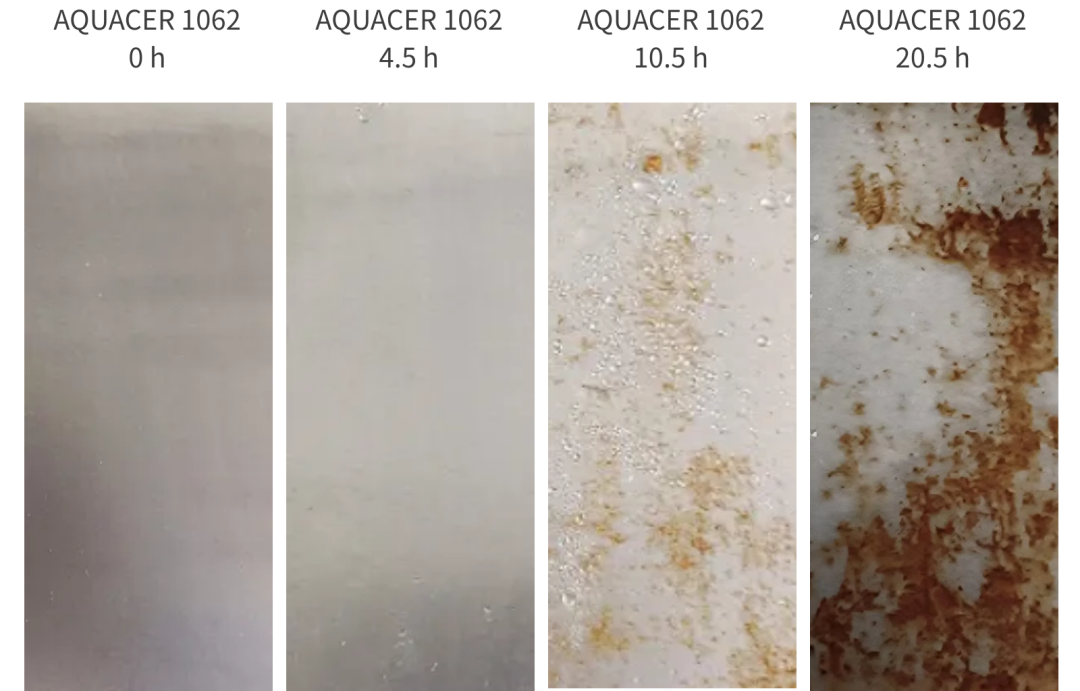

Salt Spray Test

Add AQUACER 1062.

The rust protection performance is significantly improved after 24 hours.

Test substrateQ-PANEL R-46 (Matte, Rolled Steel)

Additive dosageDilute the wax emulsion to a solid content of 20%.

Testing MethodSalt spray test (DIN EN ISO 9227:2012), the film is dried at 80°C for 3 minutes (dry film thickness: 10-20 microns), photos are taken after 24 hours.

Salt spray test

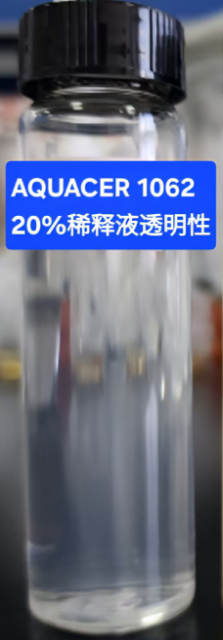

AQUACER 1062 forms a transparent film.

Provide good anti-rust protection performance.

Test substrateTinplate, 500-grit sandpaper polishing steel

Additive dosage30% diluted emulsion of wax (supply form)

Testing MethodSalt spray test (GB/T10125-2021), dry the film at 50 ℃ for 20 minutes.

Summary

AQUACER 1062 is recommended for electroplating applications and metal surface treatment. When applied to metal surfaces, AQUACER 1062 forms a protective film with good adhesion to the metal surface, effectively preventing corrosion. It is particularly suitable for galvanized steel (passivated or non-passivated) as well as non-galvanized steel, nickel, aluminum, and other non-ferrous metals.

The additive can be mixed with water in any proportion under conditions where the pH value is above 8.5. By adding silicates or common resin emulsions such as acrylic emulsions, styrene-acrylic emulsions, or polyurethane emulsions, the anti-rust performance of metal sheets treated with AQUACER 1062 can be significantly enhanced.

In addition, by adjusting the viscosity, the thickness of the dry film can be controlled. The protective film formed by AQUACER 1062 can be easily removed under alkaline conditions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage