Applications of PA6 and PA66 Materials in the Medical Field

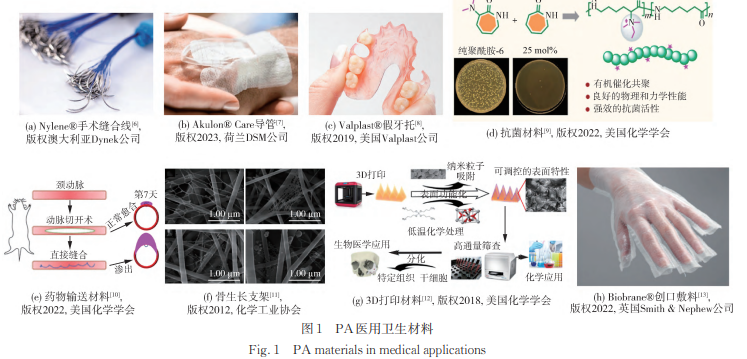

PA materials possess excellent mechanical strength, high wear resistance, corrosion resistance, and good biocompatibility. They are widely used in the preparation of medical and sanitary materials and can be made into fiber materials, molding materials, and tubes.

Currently, PA products are widely used in biomedicine for bone growth scaffolds, trauma repair materials, bone joint implants, drug delivery materials, etc. Their medical and sanitary products include surgical sutures, catheters and balloons, denture base materials, and antibacterial materials. According to the types of raw materials, the PA materials mainly used in medical and sanitary materials at present are PA6, PA66, PA11, and PA12.

The image is sourced from the internet.

Among them, PA6 and PA66 are currently the most produced PA materials. PA6 has high strength and high wear resistance. However, it has a strong hygroscopicity. Moisture can act as a plasticizer, reducing the tensile strength and stiffness of the material, while increasing the elongation and impact strength.

PA66 is currently one of the most widely used engineering thermoplastics, capable of achieving an excellent balance of strength, ductility, and heat resistance. In some applications, it can replace metal materials. This article mainly summarizes the applications of PA6 and PA66 in medical and hygiene materials.

PA6 and PA66 applications in medical and healthcare materials.

PA suture line

Medical sutures are mainly used for closing wounds, reducing infection, and protecting the underlying tissues. Materials such as gold wire, silver wire, iron wire, steel wire, catgut, animal hair, silk, bark, and plant fibers have been or are being used as medical sutures.

Some synthetic materials, such as polylactic-co-glycolic acid, can also be used as medical sutures. However, currently no medical suture can meet the medical needs for all types of wound suturing.

The choice of medical sutures depends on the number of tissue layers in the wound suturing area, the tension in the wound suturing area, the depth of suture placement, the presence of edema, the expected removal time of the sutures, the strength of the sutures, their toughness, ease of knotting, knot security, and the potential to cause inflammation.

Image source: Internet

When preparing materials for medical sutures, considerations must be given to factors such as long fiber structure, fiber thickness, degradation performance, tensile strength, surface texture, feel, stiffness, and flexibility.

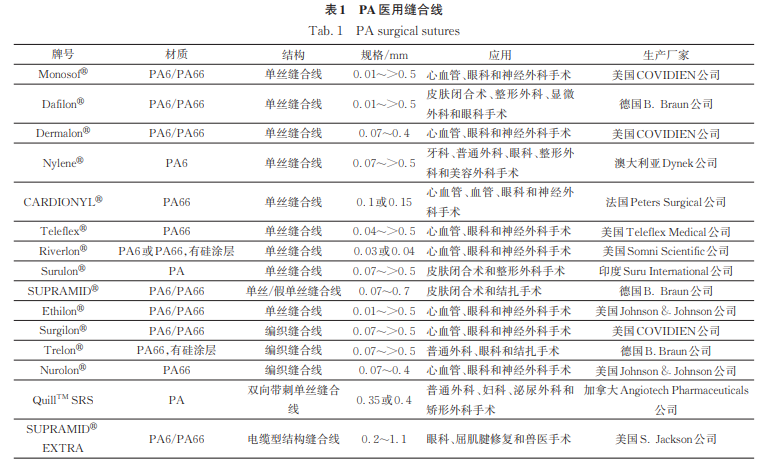

Currently commercialized PA sutures are mostly made from PA6 or PA66, featuring high strength, fine diameter, and high toughness. The characteristics of PA sutures include non-absorbability, a smooth surface with low friction resistance, durability, and elasticity. However, compared to sutures made from polypropylene (PP), their disadvantage lies in poor knot security, requiring multiple knots at the suture site to ensure wound closure.

Currently, the clinically used PA6 or PA66 medical sutures mainly consist of standard sutures, including long monofilament structures, pseudo-long monofilament structures, braided structures, bidirectional barbed monofilament structures, and core-sheath structured PA sutures. Braided PA sutures have a higher risk of infection, so their usage rate is relatively low. The most widely used PA sutures are long monofilament materials.

Image source: Internet

Medical PA catheter

Medical catheters are soft hollow tubes inserted into the human body, which help in urine drainage or serve as guidewires for various applications in the diagnosis and treatment of heart and gastrointestinal diseases. PA medical catheters can also be used in intravenous infusion, and are mainly made from PA6, PA66, PA11, and PA12.

The performance of the side tube of the catheter prepared from PA66 in various tests is consistent with that of traditional side tubes, and it can reduce the manufacturing cost of the catheter side tube by 83.3%. In the case of PA materials used for cardiac catheters, the ability to form fine tubes with good dimensional tolerances is crucial, as it meets the application requirements of the catheter to withstand cyclic compressive pressure due to heartbeats in extremely fine blood vessels.

Some catheters are equipped with soft balloons at their tips, which can be used in conjunction with the catheter to expand and clear blockages in blood vessels, deliver medications, and transport medical stents.

PA denture base material

PA is an ideal denture base material, as its toughness can provide comfort while also serving to secure the dentures. Additionally, PA materials have high elasticity, and compared to amorphous PMMA, PA is a crystalline material with low solubility, high heat resistance, high mechanical strength, and high toughness.

Antibacterial PA material

PA medical and health materials, when in contact with human tissues or in bodily fluid environments, can lead to the formation of bacterial biofilms on the surface of PA materials or instruments due to the proliferation of bacteria and other microorganisms, which affects their medical performance and may even cause strong immune responses.

In addition, the proliferation of bacteria can easily lead to infections, which in severe cases can pose a life-threatening risk. Therefore, it is necessary to endow PA medical hygienic materials with antibacterial functions to enhance their safety. This can be achieved by adding inorganic/organic antibacterial agents, antibiotics, and other bactericidal agents to the PA materials, or by employing sterilization methods to obtain clean and hygienic PA materials.

PA66 fibers or fabrics can obtain bactericidal functions by chemically modifying their surface and grafting chloramine compounds. The N-Cl bond in chloramine compounds can break in water to generate active chlorine components with strong oxidizing properties, which can non-selectively oxidize and inactivate various bacterial microorganisms, thereby achieving self-cleaning and antibacterial functions for PA materials.

Medical PA Bone Growth Scaffold

PA materials can be used alone or in combination with polymers and bioceramic materials to prepare bone tissue engineering materials. This primarily leverages the good compatibility of PA materials with human cells, as well as the excellent chemical stability of PA materials in the human body fluid environment. Researchers have used jet spinning technology to prepare PA6 patches and studied their mineralization capacity by simulating the human body fluid environment.

Researchers have also prepared composite fiber bone growth scaffolds of polyurethane/PA6/gelatin using dual-syringe electrospinning technology, which can induce hydroxyapatite formation and promote the proliferation of osteoblast-like cells. PA6 nanofiber materials are widely used as bone growth scaffold materials due to their good biocompatibility.

Drug Delivery PA

In the 1970s, PA-type drug delivery materials for medical use were extensively studied in order to develop a controllable drug delivery system. The drug delivery mechanism is primarily based on encapsulating the drug in micro-nanospheres formed by polymers or embedding it in polymer matrix materials, allowing the drug to be eluted at a stable rate to achieve drug delivery.

In PA materials, drug delivery is primarily achieved by hydrolyzing the PA material to disrupt the drug-loaded microspheres. Some researchers have obtained PA bandage materials for wound healing with an amylase-containing coating through layer-by-layer assembly technology. Other researchers have proposed using PA6 nanofiber materials or PMMA/PA6 composites to encapsulate drugs within the polymer matrix.

The main advantage of using nanofiber materials as drug delivery carriers is that they can transport drugs to specific locations in the human body.

In addition, various types of drugs can be delivered using nanofiber materials through direct encapsulation. The drug delivery function can also be applied to PA suture materials, mainly to achieve microbial inactivation at the sutured wound site.

Medical hygiene materials are special functional materials used in medical processes that come into direct or indirect contact with human tissues. Therefore, medical polymer materials, especially implantable medical polymer materials, should meet requirements such as non-toxicity, chemical inertness, biocompatibility, blood compatibility, resistance to biological aging, sterilizability, non-carcinogenicity, and ease of processing to ensure the safety of the materials for the human body.

In addition, it is necessary to select appropriate PA raw materials, processing methods, and techniques based on different intended uses to achieve the preparation of functional PA medical materials.

At the same time, other new types of PA materials also represent a development trend. Through different chemical synthesis methods, PA materials with various chemical structures and properties can be obtained, exploring their potential applications in the field of medical and sanitary materials.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track