Application of pa66 carbon fiber reinforced nylon in dart shafts

PA66 (Nylon 66) Carbon Fiber Reinforced MaterialThe creation of dart shafts is a perfect example of combining materials science with the needs of sports equipment.

1. Core Characteristics of PA66 Carbon Fiber Reinforced Material

PA66 itself is an engineering plastic with excellent performance, and the addition of carbon fiber makes it even better.

1. Extremely high strength and rigidity (high modulus):

Carbon fiberIt is a core reinforcement that provides extremely high tensile strength and flexural modulus.

Benefits broughtThe dart shaft is extremely sturdy and not easily bent or broken, remaining intact even with frequent collisions (Robin Hood, where one dart hits the tail of the previous dart).

2. Lightweighting:

The densities of carbon fiber and nylon themselves are not high, making the finished dart shafts very light.

Benefits BroughtThis allows players to allocate more weight to the barrel, achieving a front-loaded balance configuration, which is ideal for many players seeking fast, straight flight paths.

Excellent fatigue resistance and toughness:

The PA66 matrix has good toughness, and the addition of carbon fibers maintains its rigidity without making it brittle. It can withstand repeated impacts and vibrations.

BenefitsDurable and has a lifespan far exceeding many traditional materials.

Low creep property:

Under prolonged stress, the shape changes very little.

Benefits BroughtThe threads on the dart shaft can maintain their shape over time, closely integrate with the dart body, and are not prone to loosening.

Good dimensional stability:

Lower sensitivity to temperature and humidity than pure nylon, with shape and size less affected by environmental changes.

Benefits providedMaintain consistent performance across different competition environments.

2. How do these features enhance the dart-throwing experience?

1. More stable flight trajectory:

High rigidity means that the dart shaft will not experience unnecessary vibration or bending at the moment of release, ensuring that the dart flies strictly in the direction and angle at which it was released, thereby improving consistency.

2. Reduce "Robin Hood" damage:

One of the most notable advantages of carbon fiber nylon shafts is that when a subsequent dart hits the shaft of a previous dart, traditional nylon or polycarbonate shafts are easily split or damaged. In contrast, carbon fiber reinforced nylon shafts are extremely sturdy, typically resulting only in a dent or a ricochet, greatly reducing the cost of wear and tear.

3. Personalization and Feel:

Due to its lightweight and high-strength characteristics, manufacturers can produce dart shafts of various lengths and shapes (such as short and thick, or long and thin) while ensuring their strength. Players can fine-tune the weight distribution and balance of the entire dart set according to their grip style and throwing habits.

4. Excellent durability:

Whether it falls to the ground or collides with other darts, it can withstand well, making it not easy to break or deform. It is an economical choice for players seeking long-term use.

3. Potential Considerations

The cost is relatively high.:

The cost of carbon fiber and its processing technology (usually injection molding) is much higher than that of ordinary plastic, so this type of dart shaft is usually at the high end of the market.

2. Thread Strength:

Although the material itself is very sturdy, the threaded section connecting the dart shaft and the dart body is a delicate structure. If the threading precision is inadequate or it is screwed too tightly, there is still a risk of damage. However, the thread design of high-quality products usually takes this into full consideration.

3. Coordination with Flight:

The groove at the top of the dart shaft for inserting the dart flight is also sturdy. However, some players have reported that the overly rigid groove might not protect the dart flight as well as some flexible materials (such as flexible nylon). Upon impact, the force might be more readily transferred to the dart flight, leading to its damage. Nonetheless, this is generally considered a minor issue since the cost of replacing dart flights is much lower than replacing dart shafts.

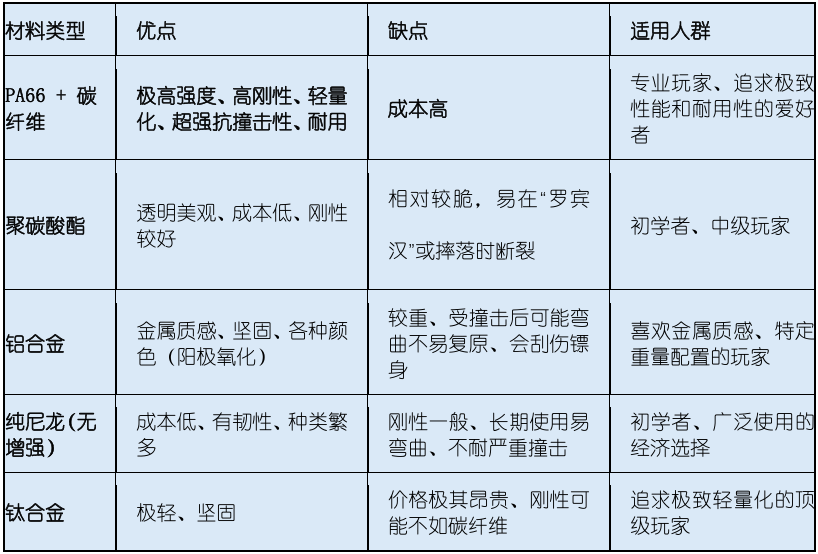

4. Comparison with Other Common Dart Shaft Materials

PA66 carbon fiber reinforced nylon is one of the top materials for making high-performance dart shafts.It balances perfectly.Lightweight, extreme rigidity, and exceptional durabilityThe three key requirements.

For serious dart players, investing in a high-quality carbon fiber nylon dart shaft can lead to more stable performance, less equipment wear, and longer lifespan, making it highly worthwhile in the long run. It represents the direction of dart equipment development under advances in material science, namely maximizing athletic performance and experience through high-tech materials.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track