Application of BYK-P 9912: Multifunctional Processing Additive in Composite Materials

From pultruded beams for wind power to aerospace prepreg components, from lightweight RTM parts for automobiles to fast-curing SMC molded plastics—advanced composite manufacturing is facing the triple challenges of diversified processes, extreme performance, and intense cost competition. The BYK-P 9912 multifunctional processing additive can help enterprises create more value in composite formulations and manufacturing processes, achieving differentiated competition.

The three main features of BYK-P 9912 product

Demolding

Ready-to-Bond

Direct bonding

Air Release

1. Demolding Efficiency: From "Single Coating" to "Continuous Production"

Pultrusion/RTM/RIMThe high molecular weight branched structure of BYK-P 9912 can form a low surface energy layer with a demolding effect on the mold surface, enabling rapid continuous production. It can achieve dozens of continuous demoldings, reducing the frequency of external mold release agent spraying, and reducing mold cleaning time by 60%.

SMC/PrepregAchieves continuous multiple demolding, maintaining stable release performance even in filled systems (such as calcium carbonate and glass microspheres), and is especially suitable for demolding complex structural parts.

Surface Performance: From "Secondary Processing" to "Ready-to-Use"

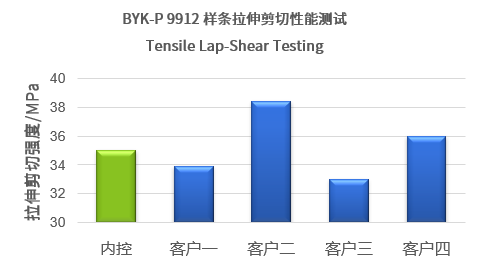

Bonding/Spraying ProcessAfter demolding, the surface does not require sanding and can meet the general adhesive strength requirements of structural adhesives (tensile shear strength ≥30MPa). It is possible to attempt direct painting without sanding, eliminating the sandblasting and surface roughening processes, thereby reducing time costs by 40%.

■Epoxy Acid Anhydride Pultrusion System Epoxy/Anhydride

■Epoxy-Amine Curing System Epoxy/Amine

3. Resin compatibility: from "dedicated to a single system" to "universal for all resins"

Chemical adaptationCompatible with epoxy-amine/epoxy-anhydride curing systems as well as polyurethane, vinyl ester, and unsaturated polyester thermosetting resin systems, providing flexibility to adapt to resin formulations for different processes.

Enhanced material general-purposeThe system exhibits stability across glass fiber, carbon fiber, aramid fiber, and hybrid fiber systems, avoiding the process adjustment costs caused by changing fiber types.

Convenience of production managementIn composite manufacturing enterprises, multiple processes and resin formulations can be adapted to avoid introducing excessive types of internal release agents, thereby reducing management costs and preventing production errors.

Cross-Process Technology Advantage: Decoding the Molecular Design of "One Agent, Multiple Uses"

The polar differentiated molecular structure of BYK-P 9912 is precisely the key to solving the challenges of multiple processes.

Low polarity release groupForms weak interactions with the surface of metal/composite molds, reducing interfacial separation force during demolding; suitable for complex curved molds (such as RTM female molds).

Moderately polar compatible segmentsForms molecular-level dispersion with the resin matrix without affecting the kinetics of the curing reaction.

Highly polar anchoring groupThrough electrostatic forces, physical entanglement with the resin is achieved, enabling the internal mold release agent remaining inside the product after sanding to remain immobile without requiring surface treatment, thus ensuring stable and reliable bonding strength.

Traditional Solution vs. BIC Solution: Multi-Process Cost Reduction Formula

Material costSingle-dose substitute release agent + defoamer + interface treatment agent, significantly reducing raw material costs.

Time costEliminate post-processing and process debugging time, improving the continuous manufacturing efficiency of prepreg molding/RTM and other methods.

Quality CostAn internal mold release agent with defoaming effect helps eliminate bubbles and improve the porosity of the product.

BYK-P 9912

Traditional Internal Release Agent

Composite additives: combining defoaming, demolding, and sanding-free properties

Single-function additive: only possesses demolding properties and has a significant impact on subsequent bonding performance.

Highly versatile: suitable for epoxy (amine-cured + anhydride-cured), PUR, UPR, VE, etc.

Poor universality: most internal release agents are only suitable for 1-2 resin systems.

Low-viscosity liquids have a relatively low impact on overall thermodynamic performance.

Reduce the overall thermodynamic performance of the product

The release agent is stable and does not separate, and can remain stably mixed with the resin system for a long time.

The release agent is prone to stratification and is difficult to stably coexist with the resin system for a long time.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track