Application and Role of Graphene in PA6 Modification

Graphene is a material composed ofSingle-layer carbon atomA two-dimensional honeycomb lattice structure material. You can think of it as a "carbon net" that is only one atom thick.Carbon atoms are connected to each other via sp² hybridized orbitals, forming a planar structure with hexagonal symmetry. This is one of the thinnest and strongest materials known to date.

Graphene possesses numerous astonishing physical and chemical properties, and the combination of these properties makes it a "miraculous material."

Extremely high strength and hardnessIt is knownThe hardest material(Approximately 200 times stronger than steel) while also possessing extremely high flexibility.

Ultra-high conductivity:Electrons can move through it with extremely high speed (about 1/300th the speed of light) and very low resistance, making it a...Materials with excellent conductivity(Superior to copper and silver).

Extremely high thermal conductivity.Its thermal conductivity performance.Far surpassing copper and silver...is an ideal thermal management material.

Ultra-thin and transparentSingle-layer graphene is only one atom thick, and is almost…Completely transparentThe light transmittance is approximately 97.7%.

Extremely large specific surface area:Due to its single-atom layer structure, it has a large surface area per unit mass, which is very important for adsorption, catalysis, energy storage, and other fields.

Excellent flexibility:It can be bent and folded without breaking.

Barrier property:Even helium (the smallest gas molecule) has difficulty penetrating a perfect single layer of graphene.

Other characteristics:It also exhibits unique quantum physical phenomena such as the quantum Hall effect and spin transport properties.

The application of graphene in the modification of PA6 (Nylon 6) is a popular research area because it can significantly enhance multiple properties of PA6, making it suitable for a wider range of applications with higher requirements.

Core application method

2. Formation of functional composite materials:By introducing graphene, PA6 is endowed with functional properties that it originally did not possess or had weakly.

Main Functions and Performance Improvements

1. Significantly enhance mechanical properties:

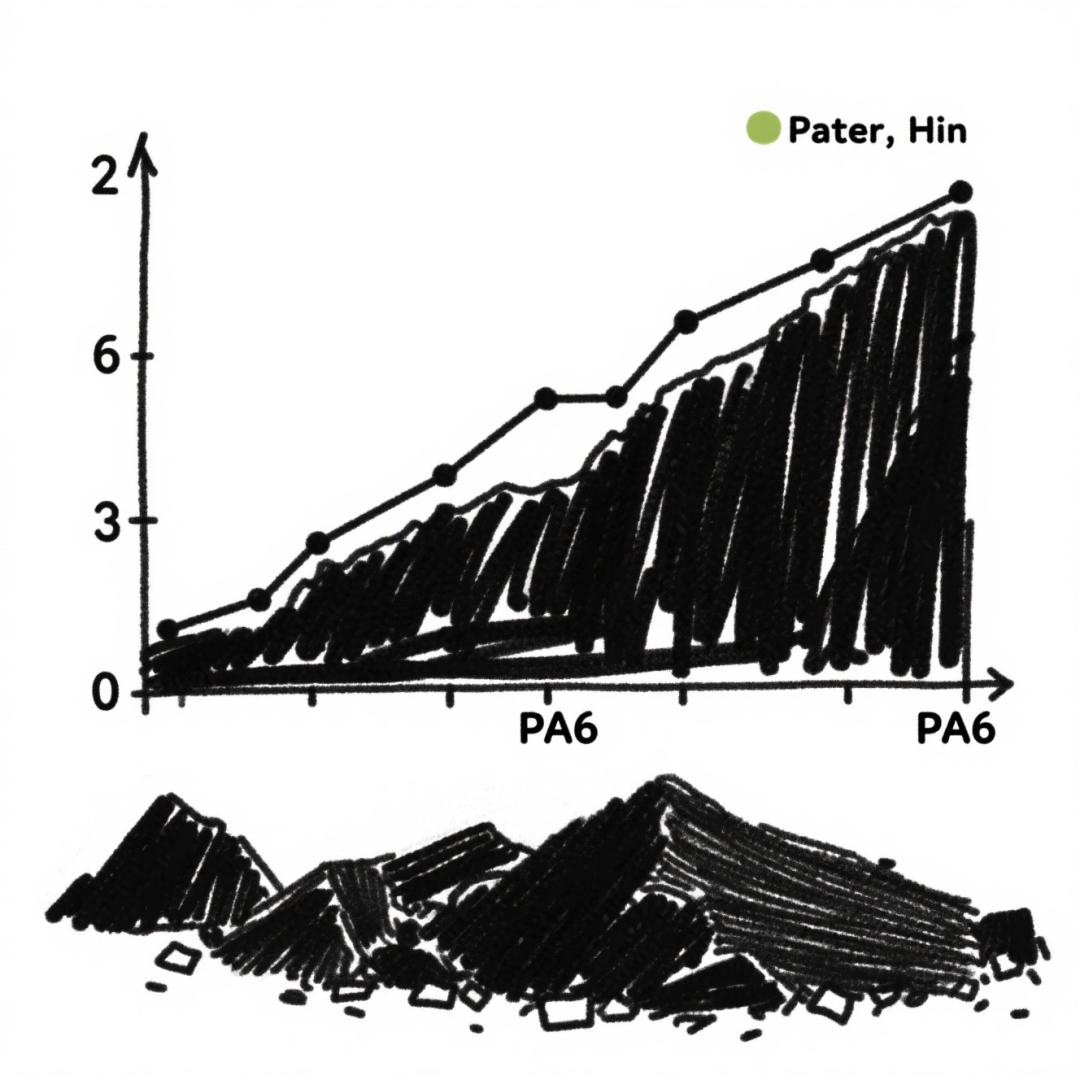

Strength and modulus enhancement:Graphene possesses extremely high intrinsic strength and modulus (approximately 1 TPa). Even with a low addition amount, it can effectively transfer stress and hinder the movement of PA6 molecular chains, thereby significantly enhancing the tensile strength, flexural strength, flexural modulus, and impact strength of the composite material (especially at low addition levels). This is one of the most notable advantages.

Increased hardness:The surface hardness and overall stiffness of the composite material are improved.

、 Endow with excellent conductivity.

Anti-static:A small amount of graphene can significantly reduce the surface resistance of PA6, bringing it to the antistatic level (10^6 - 10^9 Ω/sq), which effectively prevents static accumulation and discharge. This makes it suitable for applications such as electronic packaging, cleanroom equipment, and mining equipment.

Conductivity:When the graphene content reaches or exceeds the percolation threshold (forming a continuous conductive network), the composite material can become conductive (with surface resistance reduced to 10^0 - 10^3 Ω/sq), making it suitable for applications requiring electromagnetic shielding, electrostatic spraying, and conductive components.

、Significantly improve thermal conductivity.

Graphene has an extremely high intrinsic thermal conductivity (approximately 5000 W/mK). Adding it to PA6 can significantly enhance the thermal conductivity of the composite material and improve its heat dissipation performance. This is very important for electronic and electrical components that require good heat dissipation, such as casings, connectors, and heat sink substrates.

、Enhanced gas/liquid barrier properties:

The lamellar structure of graphene can effectively extend the diffusion path of gas molecules (such as oxygen and water vapor) or small liquid molecules in the PA6 matrix, thereby enhancing the gas and liquid barrier properties of the composite material. This is beneficial for applications such as food packaging, automotive fuel tanks, and oil pipelines.

、Improving thermal stability and flame retardancy:

Thermal stability:Graphene can hinder the thermal motion of PA6 molecular chains, increase the heat deflection temperature (HDT) and Vicat softening point of the composite material, and delay the initial temperature of thermal decomposition.

Flame resistance:Graphene sheets can form a physical barrier during combustion, hindering heat transfer, oxygen diffusion, and the escape of combustible gases. This creates a "maze effect" and enhances the char layer, working synergistically with conventional flame retardants to improve the flame retardancy of composite materials (e.g., increasing LOI and reducing heat release rate).

、Improving wear resistance and dimensional stability:

Wear resistance:The lubricating and reinforcing effects of graphene can effectively reduce the friction coefficient, improve the wear resistance of composite materials, and extend the service life of components, making it suitable for moving parts such as gears, bearings, and sliders.

Dimensional stability:The enhanced mechanical properties and reduced hygroscopicity (graphene sheets can also hinder the penetration of water molecules) collectively improve the dimensional stability of the composite material under changes in temperature and humidity.

、Reduce hygroscopicity:

Although PA6 itself has strong hygroscopicity, the layered structure of graphene can impede the penetration and diffusion of water molecules into the PA6 matrix, thereby reducing the hygroscopic rate and equilibrium moisture absorption of the composite material to some extent, and mitigating the performance degradation and dimensional changes caused by moisture absorption.

Application Challenges and Key Points

Uniformly distributed:This is the biggest challenge. There are strong van der Waals forces between graphene sheets, making them prone to agglomeration. Agglomerates become stress concentration points, which instead reduce performance. Effective surface modification (such as silane coupling agents and ionic liquid treatment) and optimized processing techniques (such as twin-screw extrusion and high-shear mixing) are required to achieve uniform dispersion at the nanoscale.

Interface integration:The interfacial bonding strength between graphene and the PA6 matrix directly affects the stress transfer efficiency. Good interfacial bonding is key to achieving excellent mechanical properties. Surface modification can improve compatibility and bonding strength.

Cost:The production cost of high-quality graphene remains relatively high, which is one of the factors limiting its large-scale industrial application. Finding cost-effective graphene raw materials and optimizing the amount added are key.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track