Apex High-Performance Polymers launches APEXLDS® laser welding material

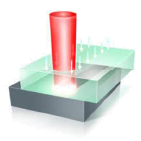

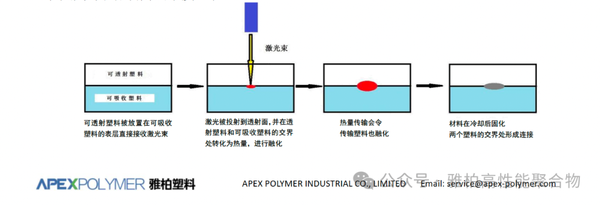

Laser welding is the transmission of laser through plastic, transmitting from one side (laser penetrates the plastic) to the other side for absorption (laser absorbs the plastic)

The commonly used laser wavelength is 800-1200 nanometers (diode or YAG laser)

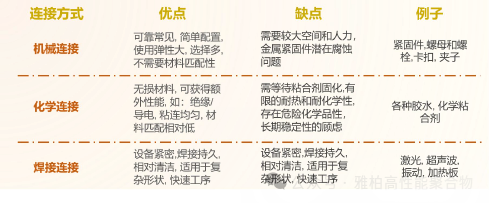

In most applications, plastic parts need to be joined or bonded together through different methods. The connection of plastics can mainly be divided into three types:

Connection methods and their advantages and disadvantages for the environment:

The figure below shows the commonly used laser welding process:

Plastics or resins suitable for laser welding have sufficient transmittance and absorbance at the laser wavelength.The main advantages of laser welding:

high precision

welding reparability

■ easily automated and controlled

■ non-destructive material

■ Can connect dissimilar materials (different rigidity, viscosity, etc.)

■ Allows complex shapes (3D and intricately contoured products)

Compared to the lower efficiency and inadequate capability of traditional welding methods, the aforementioned laser welding characteristics can be used for precision components, rapid manufacturing, and complex shapes of plastic products.

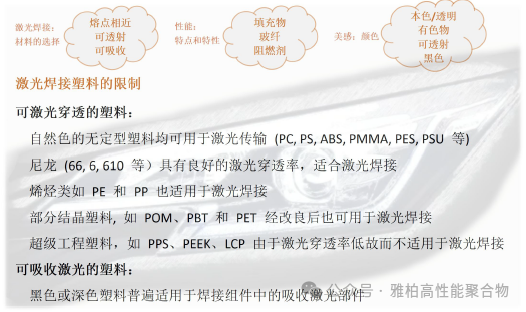

The selection of plastic is crucial for the success of laser welding.

preferred melting point close plastic

a laser-penetrable plastic and a laser-absorbent plastic

Fillers such as minerals, glass fibers, flame retardants, and colorants have a significant impact on laser welding, and specially customized formulations and colorants can enhance the performance of laser welding.

color selection

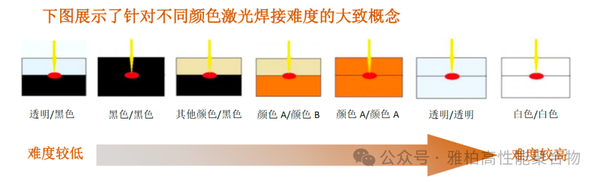

The choice of color is very important for laser welding.

The ideal combination is that the color of the laser-facing surface allows the laser beam to pass through, and the absorbent color heats/melts at the interface.

However, in practical applications, the consideration of color is diverse.

Therefore, manufacturers and modification plants need to customize special formulas and welding procedures to ensure the success of laser welding.

The figure below illustrates a general concept of the difficulty of welding with different colored lasers.

APEXLDS PA6,PA66,PBT,PC,PARA,PPS,PPA product list

We have extensive experience in component assembly and have successfully helped clients solve various challenges related to plastic connections in the past.

Currently, we have 4 types of commercialized modified plastics available for laser welding.

We can also provide consultation and advice on color aspects for black/dark laser welding.

APEXLDS PA6:N6G2 LT

APEXLDS PA66:N1300S LT

APEXLDS PBT:T990G30 LT

APEXLDS PC:ML3420 LT

Ultra-low warp PBT has been launched and commercialized

Application Case: Microwave Radar Controller Housing, Material: T990G30 LT.

High-transparency modified PPS specifications are about to be launched.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track