Anti-aging masterbatch selection guide: 3 Steps to Choose Right and Extend Product Lifespan by 5 Times

Plastic products, when exposed to environmental factors such as ultraviolet light, heat, oxygen, and moisture outdoors, can undergo polymer chain scission or crosslinking, leading to material degradation.Discoloration, brittleness, decreased strength, surface chalkingThis is aging.

Anti-aging masterbatch is a type of pellet in which high concentrations of anti-aging additives (such as antioxidants and light stabilizers) are pre-dispersed in a carrier resin. It acts like an "invisible protective suit" for plastic products, efficiently absorbing ultraviolet rays and terminating oxidative chain reactions, fundamentally delaying the aging process. This is the core technology for enhancing the durability and added value of products.

Core 3-step method: Scientifically choose the right masterbatch, boost efficiency by 5 times.

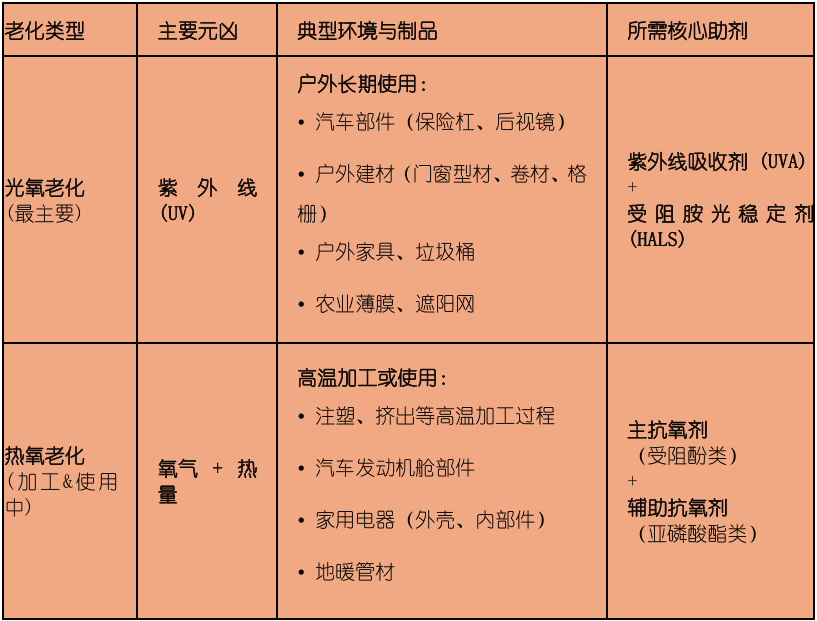

Step 1: Accurate Diagnosis - Identify the Type of Aging that Will Cause Your Product to "Die"

This is the most critical step. If you choose the wrong direction, everything goes back to zero. You need to perform a "diagnosis" on your product like a doctor.

Action Guide:

1. Draw the product life cycle diagram:What environments will your products experience from production to disposal? Will they be exposed to prolonged sunlight or indoor lighting? Will they come into contact with high temperatures?

Determine the dominant aging factor:If your product is mainly used outdoors,Photodegradation is the primary enemy.If it is primarily used in high-temperature environments, it is necessary to choose masterbatches containing efficient UVA and HALS.Thermal-oxidative aging protectionIt is the key point.

Objective: Ensure that the masterbatch formulation you choose can precisely combat the "number one killer" that causes the aging of your products.

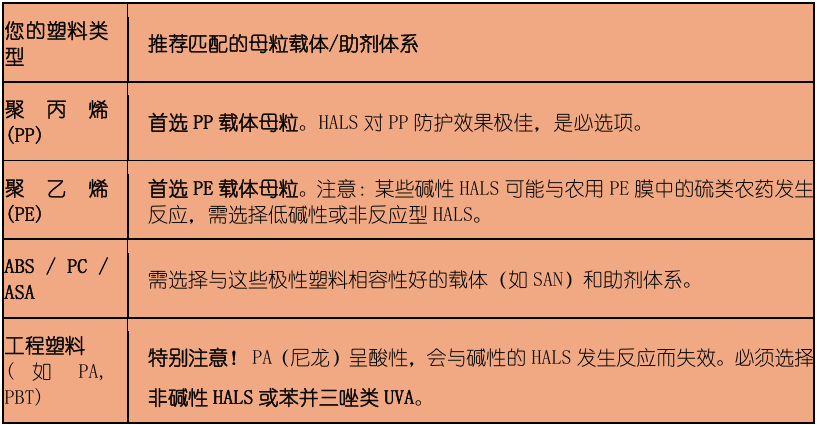

Once the cause of the problem has been diagnosed, a "prescription" needs to be written. The "medicine" here must match your "body" (base plastic) and "constitution" (processing technique).

1. Match base plastic (compatibility is the lifeline)

Different plastics have different molecular structures and require specific types of anti-aging additives for good compatibility. Incompatibility can lead to "blooming" (the additive exuding to the surface) or "migration," which not only results in failure but also contaminates the surface of the product.

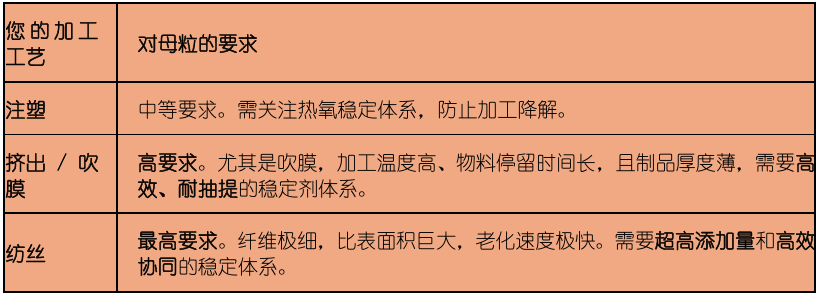

2. Match the processing technology (machinability is the guarantee)

High temperature and high shear force during the processing can deplete anti-aging additives.

3. Match the final requirements (performance is the goal)

Life expectancy:Do you want a lifespan of 1 year, 3 years, 5 years, or 10 years? The higher the lifespan requirement, the more additives and efficiency are needed.

Appearance Requirements:"Is it necessary to maintain high gloss and colorless transparency? This requires the additive itself to be light in color and low in impurities."

Regulatory Certification:Is the product intended for food contact, children's toys, or medical use? You must choose compliant options.FDA、EU、RoHSMasterbatch of corresponding regulations.

Objective: Find a masterbatch that is perfectly compatible with your base plastic, processing techniques, and final performance requirements to avoid "incompatibility."

Step Three: Savvy Verification - Use a "discerning eye" to screen suppliers and products.

After theoretical matching, it is necessary to verify through practice. This step helps you to identify the strength of the supplier and the actual effectiveness of the product.

1. Evaluate the technical capability of the supplier.

Can you provide technical advice?An excellent supplier will proactively inquire about your specific application and provide targeted formulation suggestions.

Are there any success stories?I would like to inquire if there are any successful cases of applications similar to yours (such as those also involved in making PP car bumpers).

Can you provide the test report?Request to view the masterbatch.Heavy metals, RoHSWaiting for the safety inspection report.

2. Request samples and conduct a "micro-test".

Appearance Inspection:Are the masterbatch granules uniform, dust-free, and of consistent color?

Machinability test: Translate the above content into English and output the translation directly without any explanation.Conduct a trial processing on a small laboratory machine to observe if there is any odor, whether the smoke volume is excessive, and whether it disperses easily (no crystal points).

Key Performance Verification (Crucial for Convincing the Boss):

Artificial Accelerated Aging Test:Place the sample with the masterbatch and the blank sample simultaneously.QUV Aging Test ChamberThis is the most authoritative and fastest verification method. Typically, after a few hundred hours of testing, the blank sample may have severely chalked and discolored, while the qualified sample shows very little change.The promise of "extending lifespan by 5 times" is supported by this kind of test data.

Thermal Oxidative Aging Test (OIT):The oxidation induction time (OIT) can be tested using a DSC instrument to quantify the thermal stability of materials. The longer the OIT time, the better the thermal stability.

Objective: Verify the actual effectiveness of the masterbatch and the professionalism of the supplier through small-scale testing, to avoid the risks of bulk purchasing.

Summary: Select Action List

1. Ask yourself:My product mainly faces threats from ultraviolet rays or high temperatures? (Step 1: Diagnosis)

Ask the supplier:My base material is PP. Can your masterbatch carrier and additive system ensure compatibility? My processing technology is XX. How is the processing resistance? (Step 2: Matching)

3. Verification: Translate the above content into English and directly output the translation result without any explanation.Please provide samples and third-party inspection reports. We need to conduct a QUV test to review the data. (Step 3: Verification)

Remember this formula:

Accurate diagnosis (cause) + deep matching (prescription) + astute validation (clinical trials) = substantial extension of product lifespan

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track