Another New Player Joins the PEEK Track! Why Is "Industrial Gold" So Highly Sought After?

A new player joins the PEEK track!

Fuchun Dyeing & Weaving:

New business focuses on downstream applications of PEEK

Not long ago, Fuchun Dyeing and Weaving invested in establishing a wholly-owned subsidiary, Wuhu Fuchun High-Tech Co., Ltd., focusing on the research, innovation, and industrialization of "industrial gold" PEEK.

It is reported that Fuchun Dyeing and Weaving is currently focusing on downstream applications of PEEK, such as semiconductors, medical devices, and lightweight solutions for humanoid robots. It will also actively explore applications in new energy vehicles and the low-altitude economy sectors.

Guoen Co., Ltd.:

The subsidiary plans to launch a PEEK materials project.

On August 1st, Guoen Co., Ltd. announced that it has completed the development of production technology and core processes for PEEK materials. The company plans to establish a fully integrated vertical platform covering the entire PEEK industry chain—from polymerization to compounding and final products—through its wholly-owned subsidiary, Zhejiang Guoen Chemical Co., Ltd. It also intends to build a pilot platform for styrene engineering material polymerization and launch a project for 300,000 tons/year of organic polymer modification and composite materials.

At present, the project has obtained the record-filing from the Economic Development Bureau of the Zhoushan High-tech Industrial Park Administrative Committee.

The total investment of the project is 960 million yuan, intending to build 2 PEEK polymerization production lines; 1 pilot-scale polymerization unit for styrene-based engineering materials; and 36 production lines for modified and composite materials.

What makes PEEK so attractive?

Why is it so popular?

This starts with PEEK's "all-around skills."

First, let's take a look at what PEEK is.

PEEK:

High-end engineering plastics at the pinnacle of the pyramid

Polyether ether ketone (PEEK), belonging to the polyaryletherketone (PAEK) family, is a crystalline aromatic thermoplastic polymer composed of phenylene rings connected by ether and carbonyl linkages.

▲Photo taken at CHINAPLAS 2025 International Rubber and Plastics Exhibition, same below.

PEEK, due to its excellent mechanical properties, high heat resistance, and corrosion resistance, is also known as the "pinnacle of high-end engineering plastics."

Compared to conventional metals, PEEK material can significantly reduce the weight while meeting the required strength, achieving lightweighting. Specifically, the tensile strength of PEEK is three times that of aluminum alloy and twice that of steel. The flexural modulus of PEEK is four times that of aluminum alloy and 1.5 times that of steel.

With the rapid development of emerging fields such as humanoid robots and the low-altitude economy, PEEK has emerged with its "full set of skills," and market demand is continuously rising.

Humanoid robot field

The requirements for lightweight, high strength, and high precision materials in humanoid robots align well with the properties of PEEK material. PEEK is used in components such as joints, bearings, and gears in humanoid robots.

Additionally, in special environments such as high temperature, high humidity, and chemical corrosion, PEEK materials exhibit outstanding chemical resistance and stability, significantly expanding the application scenarios of humanoid robots.

▲Watts DuraKraft™ PEEK material is used in the joint components of humanoid robots.

Low-altitude economy sector

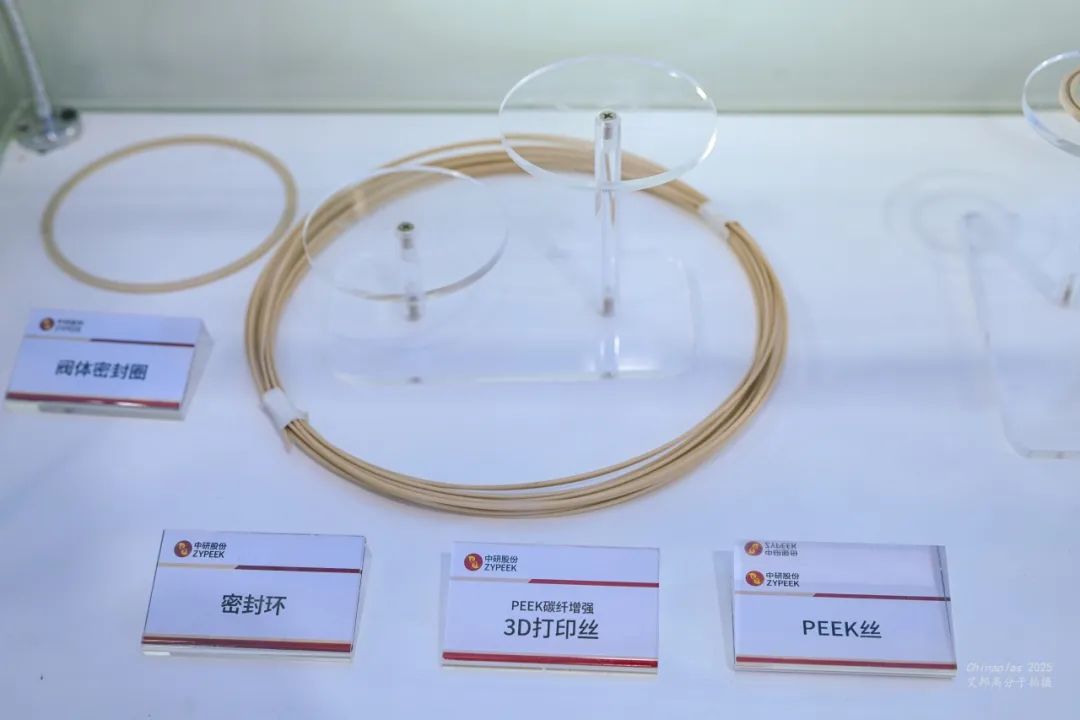

Carbon fiber reinforced PEEK can be used to manufacture drone frames, propellers, and engine components, as well as lightweight structural parts for low-altitude flying cars (such as seats, doors, and window frames). It can also be used to produce housings for sensors and control systems.

▲Nanjing Julong showcased unmanned aerial vehicle structural components and parts made primarily from high-performance functional materials such as PEEK, PPS, and carbon fiber composites at CHINAPLAS 2025.

Other Fields

Medical and Health: PEEK is widely used in spinal surgery, joint replacement, and trauma repair due to its excellent biocompatibility, elasticity modulus similar to bone tissue, and good wear resistance.

Zhongyan Co., Ltd. showcased medical implant-grade PEEK products at CHINAPLAS 2025.

Automotive: PEEK material can be used to manufacture lightweight components such as engine covers, bearings, brakes, ABS valves, and clutches.

Semiconductors: PEEK profiles for semiconductor manufacturing are specially treated to meet the specific requirements of semiconductor production processes, such as anti-static properties, low outgassing, and extremely high mechanical strength. They are mainly used in components such as CMP retaining rings, wafer carriers, and wafer chucks.

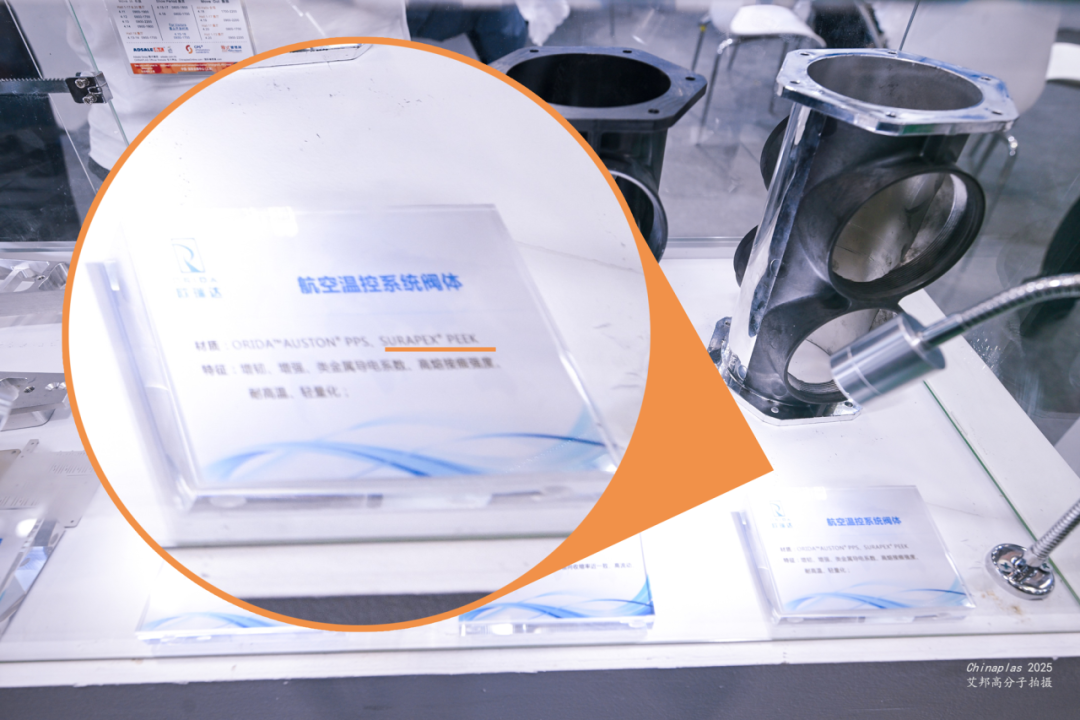

Aerospace: Due to its lightweight and high-strength properties, PEEK material has become an ideal choice for manufacturing internal structural components of aircraft.

PEEK material has excellent wear resistance and corrosion resistance, and can withstand the high temperature, high pressure, and high-speed operating environment inside aero engines. Therefore, PEEK bearings and seals have been widely used in aero engines.

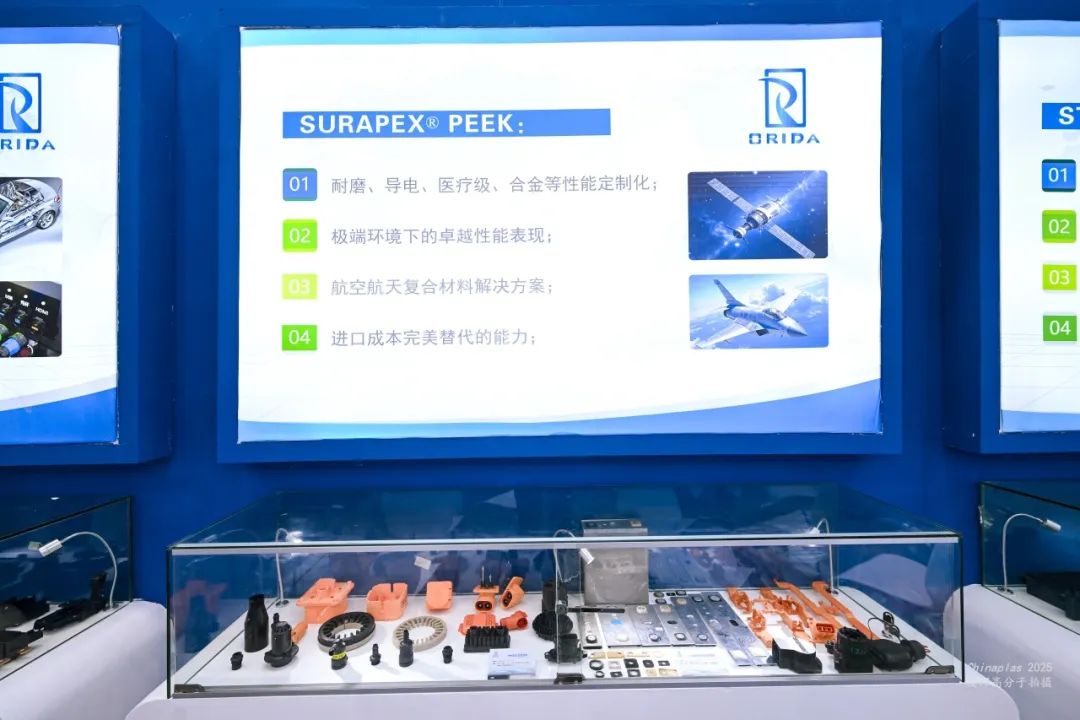

▲Aerospace composite material solutions showcased by Orida at CHINAPLAS 2025.

Seeing these high-end and highly demanded applications, it is easy to understand why PEEK has become so popular.

According to incomplete statistics, major domestic enterprises include Jida Special Plastics, Junhua Co., Zhongyan Co., Pengfulong, Kingfa Sci & Tech, Water Co., Nanjing Julong, Haoran Special Plastics, and Panjin Weiyingxing, among others.

Junhua Co., Ltd.

In August this year, Jiangsu Junhua High Performance Specialty Engineering Plastics Co., Ltd. inaugurated its new intelligent factory, officially completing the project with an annual production capacity of 1,000 tons of polyether ether ketone (PEEK), 100 tons of polyimide (PI) materials and related products, and 10,000 sets of precision molds.

Shandong Junhao High-Performance Polymers Co., Ltd., a wholly-owned subsidiary of Junhua Co., Ltd., owns production facilities with an annual capacity of 2,500 tons of industrial-grade PEEK, 300 tons of medical-grade PEEK, and 600 tons of polyimide.

Zhongyan Co., Ltd.

Zhongyan Co., Ltd. currently has a production capacity of 1,000 tons per year of polyether ether ketone (PEEK). The company's main products are resin-form PEEK, with a product system comprising 52 specifications and grades.

In addition, the company's "Annual Production of 5,000 Tons of Polyether Ether Ketone (PEEK) Deep Processing Series Products Comprehensive Plant (Phase II) Project" is progressing in an orderly manner.

Jida Special Plastics

Jida Special Plastics has an annual production capacity of 500 tons of polyether ether ketone (PEEK), 500 tons of polyether ether ketone ketone (PEEKK), 500 tons of polyether ketone (PEK), and 100 tons of polyethersulfone (PES) resins and their modified materials.

Peng Fu Long

As a major producer of polyether ether ketone (PEEK) and one of the drafters of national standards, Pengfulong has overcome bottlenecks in synthetic chemical processes and key application technologies. Its holding subsidiary, Zhongju Bio, has completed over 20 clinical trials of medical-grade polyaryletherketone, achieving a breakthrough in domestic production.

In 2025, the second phase of the Pengfulong Advanced Polymer Materials Future Factory is set to commence production, with an annual production capacity of polyaryletherketone reaching 1,500 tons.

Watts Co., Ltd.

Watts Co., Ltd. possesses a complete industrial chain capability for PEEK, encompassing "polymerization, modification, and profile processing."

In May of this year, Chongqing Watt Zhicheng New Material Technology Co., Ltd., a wholly-owned subsidiary of Watt Co., Ltd., officially obtained the "Work Safety Permit," marking the commencement of formal production for the 20,000-ton-per-year LCP resin materials project (Phase I and II) and the 1,000-ton-per-year PAEK resin materials project (Phase I).

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track