AI + Advanced Manufacturing! Topstar Deepens Cooperation with Huawei and openEuler, Accelerating the Implementation of Embodied Intelligence Technology

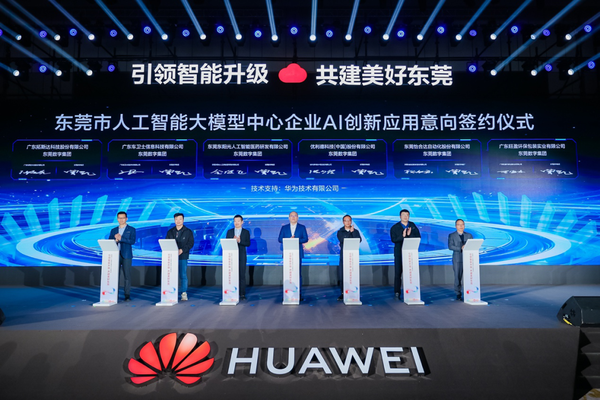

On March 19, the country's first city-level large model center for the manufacturing industry - the Dongguan Artificial Intelligence Large Model Center - officially began operations. Six Dongguan manufacturing companies, including Tosda, East Sunshine, Uni-Trend, Car Guardian, Yiheda, and Wangying Printing, signed an "intentional cooperation agreement for enterprise AI innovation applications at the Dongguan Artificial Intelligence Large Model Center," marking their lead in exploring innovative applications of artificial intelligence in the manufacturing sector.

01

Tosda deepens cooperation with Huawei Cloud

promote intelligent manufacturing upgrade

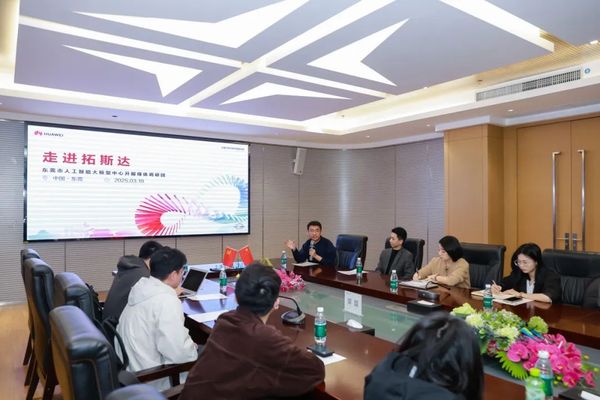

On the same day, Huawei Cloud, together with several major domestic media outlets including CCTV.com, China News Service, and Southern Daily, visited Tosda to learn about the cooperation outcomes. Dr. Zhang Xiaohui, Chief Engineer of Tosda, shared the cooperation journey with the media. As early as 2021, Tosda collaborated with Guochuang Gongruan to develop a new generation X5 robot motion control platform based on the Euler operating system (openEuler). This platform played a crucial role similar to that of the "cerebellum and spine" in the integration of intelligence and embodiment, serving as a core component for achieving embodied intelligence. By uploading real-time data from the robot's body to the cloud and leveraging the powerful computing capabilities of the cloud, the new X5 platform can accurately receive and execute instructions issued by large models, significantly improving the efficiency and effectiveness of intelligent robots in actual working environments.

This time, Topstar collaborates with Huawei Cloud, using the Tianchou solver to optimize the entire chain from raw material design to sheet cutting, seeking the optimal solution for cutting. After the implementation of this solution, it can effectively reduce material costs and improve collaboration efficiency. Dr. Zhang Xiaohui stated: "Huawei Cloud provides underlying technical support for AI applications, demonstrating its influence in the field of artificial intelligence technology. The cooperation case with Huawei Cloud validates the role of large AI models and the new generation X5 robot motion control platform in enhancing the intelligence level of industrial robots, showcasing Huawei Cloud's strong capabilities in industrial application areas."

02

join hands with openEuler

Continuous exploration of AI + advanced manufacturing

Meanwhile, Topstar was invited to participate in the Huawei China Partner Conference 2025, showcasing a new generation of intelligent robot control platforms built on Kunpeng and openEuler.

The control platform adopts 18+16 axis millisecond-level collaborative control technology, supporting complex scene multi-machine linkage; multi-modal data acquisition and AI training closed loop, achieving high-precision industrial data real-time synchronization and model iteration; supports multiple dynamics algorithms, meeting the needs of high-end scenarios such as precision, assembly, and human-robot collaboration; based on containerization technology, it flexibly and elastically deploys robot control systems, promoting the application and implementation of future industrial control technologies such as hybrid deployment and cloud-based control; provides a variety of native API interfaces for programming languages and an offline programming development platform and other integrated development tools, improving the efficiency of robot application development and accelerating product launch.

03

look to the future

accelerate the implementation of embodied intelligence technology

Tosda will continue to collaborate with large AI model companies to jointly develop industry-specific models for intelligent robot application scenarios. Based on the "cloud-edge-device" collaborative system, the R&D team will conduct more flexible and intelligent dual-arm robot validation work, accelerating the application of embodied intelligence technology in industrial settings. By enhancing the intelligence level and scenario adaptability of robots, Tosda is committed to transforming robots from being able to "do work" to "knowing how to work," striving to become the "smartest robots that understand craftsmanship," and injecting new momentum into the intelligent transformation of manufacturing.

In the future, as more AI + advanced manufacturing scenarios are implemented, Tossida will continue to join hands with partners to jointly promote high-quality development of industrial intelligence.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track