A Comprehensive Overview of Polyphenylene Oxide (PPO) Polymer Manufacturers!

PPO has already been widely applied in fields such as photovoltaics, automobiles, electronics, home appliances, and water treatment. In addition, PPO is also an important material in national strategic emerging industries, such as 5G communications, new energy vehicles, and integrated circuit chips. In recent years, the development speed of PPO has accelerated.

Below is an introduction to the major PPO material polymer production enterprises at home and abroad (in no particular order).

SABIC

In 2008, SABIC acquired GE's engineering plastics department for $11.6 billion, which included GE's PPE project and the world's most comprehensive range of PPO alloy types.

SABIC's NORYL™ SA90 and SA9000 resins are unique low molecular weight polyphenylene ether (PPE) telechelic copolymers that can be used as additives in high-performance copper clad laminates, improving the product's dielectric properties, dimensional stability, and mechanical properties.

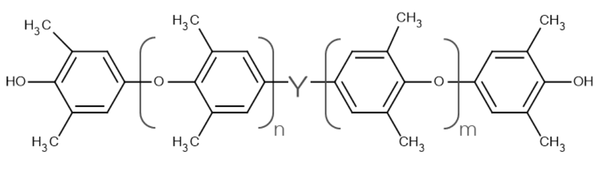

NORYL™ SA90

NORYL™ SA90 is a dihydroxy functional oligomeric polyphenylene ether suitable for epoxy-containing low to mid loss PCBs.

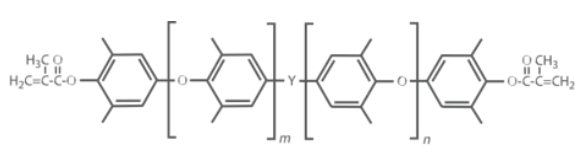

NORYL™SA9000

NORYL™ SA9000 is a dipropenyl-terminated polyphenylene ether oligomer product suitable for non-epoxy low-loss PCBs. Last year, SABIC announced a doubling of the NORYL™ SA9000 specialty resin production capacity at its Indian plant to better support the rapidly growing demand for high-performance printed circuit boards (PCBs) used in 5G base stations and high-speed servers.

Japanese Mitsubishi Gas Chemical

Mitsubishi Gas Chemical Company, Inc. is one of the world's renowned chemical enterprises, with a leading global advantage in the production process of ultra-pure electronic-grade and food-grade hydrogen peroxide. It mainly engages in the production and trading of inorganic and organic chemical products, petrochemical products, synthetic resins, synthetic rubbers, and other polymer products. Its products span multiple fields including chemicals, pharmaceuticals, food, health, and IT.

Mitsubishi Gas's ethylbenzene polyphenylene ether resin, trade name OPE-2St, has the characteristics of low dielectric constant and low dielectric loss, suitable for ultra-low loss copper clad laminates.

Asahi Kasei

Asahi Kasei produces PPE using 2,6-xylenol as the raw material, which is then mixed with various resins such as polystyrene (PS), polyamide (PA), polypropylene (PP), polyphenylene sulfide (PPS), and polyphthalamide (PPA) to create polymer alloys, offering a rich variety of material grades. It is one of the major global suppliers of low molecular weight PPO.

XYRON™ is Asahi Kasei's modified PPE (modified polyphenylene ether or mPPE) resin product series. It features excellent heat resistance, flame retardancy, electrical properties, dimensional stability, low water absorption, and light specific gravity.

Nantong Xingchen Synthetic Materials Co., Ltd.

In 2000, Bluestar Chemical New Materials Co., Ltd. and Nantong Synthetic Materials Factory jointly invested to establish Nantong Starry Synthetic Materials Co., Ltd. China Bluestar is currently the largest PPO manufacturer in the country, with BS009 and BS012 being low molecular weight PPO.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track