A Comprehensive Overview of Nylon Release Agents in One Article

Nylon release agents are essential auxiliary materials to ensure the efficient, high-quality, and low-cost production of nylon products. Given the characteristics of nylon materials and the complex processing challenges, it is crucial to select the appropriate type of release agent and master the correct application process.

Using a small amount of release agent can sometimes improve and eliminate defects such as bubbles.

1. Core Function

In the injection molding, die casting, or extrusion molding processes of nylon (PA6, PA66, PA12, PA46, glass fiber reinforced nylon, etc.), the core function of the release agent is:

1. Formation of an isolation membrane:Form an effective physical or chemical isolation layer on the mold surface.

2. Reduce interfacial tension:Significantly reduce the adhesion between molten nylon and the surface of the mold metal.

3. Facilitate demolding:To ensure that the molded nylon products can be smoothly and completely removed from the mold cavity, avoiding:

Sticking/Demolding:The product is partially or entirely stuck inside the mold cavity.

Top white/top crack:The product becomes white or cracks at the ejector pin area due to excessive adhesion.

Strain/ScratchDuring the demolding process, the surface of the product is scratched by the mold.

Transformation:Difficulty in demolding leads to deformation of the product.

4. Mold protection:Reduce the corrosion, wear, and fouling of the mold surface by molten nylon.

5. Improve product surface quality:Reduce surface defects (such as flow marks and haze) and improve glossiness (some release agents have this effect).

2. Key Challenges (The Special Characteristics of Nylon Materials)

High melting point & high viscosity:Nylon has a high melting temperature (PA66 is about 260-290°C), relatively high melt viscosity, and strong adhesion to the mold.

2. Strong polarity:Nylon molecular chains contain a large number of polar amide groups (-CONH-), which tend to undergo strong physical adsorption or even chemical interactions with the surface of metal molds.

3. Crystallinity:During cooling and shrinkage, it is easy to wrap around the core or get stuck in the cavity.

4. Hygroscopicity:Nylon easily absorbs moisture, and inadequately dried raw materials can produce gas (water vapor) at high temperatures, which may lead to defects such as flow marks and silver streaks on the products, and indirectly affect demolding.

5. Glass fiber reinforcement:Adding glass fiber (GF) improves strength and rigidity, but glass fiber significantly increases the friction and wear between the melt and the mold, making demolding more difficult and placing higher demands on the lubricity and wear resistance of the release agent.

3. Main Types and Characteristics

By form and application method:

1. External Release Agent (Spray Type):

Solvent-based release agent:

Principle:Dissolve active ingredients (such as silicone oil, wax, fluoropolymer, etc.) in volatile organic solvents (such as isopropanol, heptane, D40, etc.).

Advantages:Dries quickly, forms a thin and uniform film, has good demolding effect (especially in the early stages), and is usually relatively low-priced.

Disadvantages:High VOC emissions (environmental pressure), flammable and explosive (safety hazards), solvent evaporation may lead to uneven film thickness, long-term use may result in residue accumulation on molds or products (affecting secondary processing such as coating, bonding, printing), excessive use may cause "oily blooms" or "stickiness" on the product surface.

Common active ingredients:Modified silicone oil (such as polyether-modified polysiloxane), fluorocarbon compounds, specialty synthetic waxes.

Water-based (emulsion type) release agent:

Principle:Emulsify and disperse the active ingredients (such as silicone oil, wax, fluoropolymers, etc.) in water.

Advantages: Environmentally friendly (very low VOC), non-flammable (high safety), relatively low residue (less impact on secondary processing), easy to clean.

Disadvantages: slow drying (requires mold drying or extended waiting time), high latent heat of water evaporation may lead to local mold temperature drop (affecting molding stability), watermarks may form on high-gloss molds, initial demolding force may be slightly inferior to high-quality solvent-based (but the gap is narrowing with continuous formulation improvements), sensitive to hard water (may lead to scaling).

Common active ingredients: modified silicone oil emulsion (polyether-modified siloxane emulsion), wax emulsion, fluorocarbon emulsion.

Release agent without silicone:

Principle:The main components are fluoropolymers, special synthetic waxes (amide wax, ester wax, etc.), or polymer surfactants, and it is completely free of organosilicon.

Advantages: Absolutely avoids silicone contamination, making it the first choice for nylon products that require subsequent processing such as spraying, electroplating, bonding, and printing. Minimal residue, with high surface tension of the products.

Disadvantages: The cost is usually higher, the release force may be slightly lower than that of high-performance silicones (but sufficient for most nylon applications), and special attention needs to be paid to the formulation for heat resistance/durability.

Semi-permanent release agent:

Principle:Most are solvent-based or water-based, but contain special polymer components (such as PTFE, modified silicone resin, or special cross-linked polymers), which can form a more durable and robust film on the surface of the mold. A single application can provide release for multiple cycles (dozens, hundreds, or even more).

Advantages: Significantly improves production efficiency (reduces the number of spraying cycles), reduces downtime, provides stable demolding performance, and slows down residue accumulation.

Disadvantages: High initial cost, high requirements for the spraying process (must be uniform), if the film is damaged or contaminated, it is difficult to repair locally (may require complete removal and reapplication), and removal is relatively difficult.

Especially suitable for: nylon products with complex structures, deep cavities, and small draft angles; production lines with a high degree of automation.

2. Internal Release Agent (Additive Type):

Principle:Before nylon pelletizing or injection molding, a small amount (0.1%-2%) of mold release agent (usually amide wax, stearate, silicone masterbatch, fluoropolymer powder, etc.) is directly mixed into the nylon raw material.

Advantages:Convenient to use (no need for mold spraying), no VOC issues, stable and uniform release effect, can improve melt flowability, and reduce internal stress in products.

Disadvantages:May affect the physical properties of the product (especially mechanical properties and heat distortion temperature), transparency (if required), and surface gloss; excessive addition may cause blooming (exudation); may adversely affect subsequent secondary processing (especially bonding and painting), requiring careful selection of type and dosage; increased cost.

Key to Selection:Compatibility with the nylon matrix, thermal stability, migration resistance, and impact on final properties.

Application: Translate the above content into English and output only the translation without any explanation.Commonly used in situations where demolding requirements are not extremely stringent, and where secondary processing demands are low or can be addressed through surface treatment; sometimes used in conjunction with external release agents.

4. Core Performance Requirements (for Nylon)

Excellent release ability:This is the most basic requirement, which can effectively overcome the high adhesion of nylon melt to the mold.

2. High temperature resistance:It must withstand the high mold temperatures during nylon injection molding (commonly between 80-160°C or even higher), with the active components neither decomposing nor losing effectiveness.

3. Low residue & easy transferability:The release agent should primarily transfer to the product, with minimal residue and easy removal, to avoid:

Mold foulingAffect the appearance and dimensional accuracy of the products, increasing the cleaning frequency.

Secondary processing defects of products:Silicone contamination is the nemesis of spraying, bonding, and printing. Silicone-free or low-migration silicones (polyether-modified siloxanes) are preferred.

4. Minimal impact on the surface of the product:

Does not affect the glossiness of the product itself (or can enhance the glossiness).

Does not cause surface defects of the product (such as oil spots, stickiness, matte finish, whitening).

This does not affect the color and transparency of the product (if needed).

5. Good spreading and film-forming properties:Can quickly and uniformly spread on the mold surface to form a continuous, dense, and thin (usually nano- to micron-scale) isolation film.

6. Lubricity (especially for glass fiber reinforced nylon):Reduce the scratching and wear of molds by glass fibers, protect the molds, and reduce demolding resistance.

7. Chemical Stability:Does not react adversely with nylon melt or molds.

8. Environmental Protection and Safety:Low VOC, non-flammable, low-toxicity or non-toxic release agents are trends and regulatory requirements (water-based, silicone-free, high-solids solvent-based).

9. Operational convenience:Easy to spray (good atomization), fast drying (solvent-based) or easy to bake dry (water-based), and low odor.

5. Selection Guide

1. Priority should be given to subsequent processing.

For applications requiring painting, electroplating, bonding, and printing → Use non-silicone release agents (preferably fluorinated or special wax-based) or low-migration polyether-modified silicone release agents.Be sure to obtain a compatibility report from the release agent supplier.

No special secondary processing requirements → High-performance silicone types (solvent-based or water-based) or semi-permanent types can be considered.

2. Consider the product complexity and demolding difficulty:

Simple structure and large draft angle → conventional release agent is sufficient.

Complex structure, deep cavity, slender core pin, small draft angleSemi-permanent mold release agentorHigh-performance, highly lubricating release agent (such as fluorosilicone-based)is a better choice.

3. Consider the glass fiber content:

High glass fiber content (>30%) → requiredHigh lubricity and wear resistanceRelease agents (containing fluorine, containing PTFE, high silicon content, or special lubricating additives). Semi-permanent effect is significant.

4. Consider production efficiency requirements:

Pursue high-speed production and reduce downtime.Semi-permanent release agentThe advantages are obvious.

Considering environmental regulations and factory safety requirements:

Strictly limit VOCs →Water-based release agent。

High fire protection requirementsWater-based or solvent-free release agent。

5. Mold condition:

New molds or high-gloss molds → choose release agents that provide uniform film formation and do not affect gloss (pay attention to water stains for water-based agents).

Old molds with slight damage → release agents with better filling and covering properties can be selected.

VI. Key Points of Application

1. Mold Cleaning:Before spraying the release agent,Be sure to thoroughly clean the mold.Remove residues of old release agents, oil stains, nylon decomposition products, etc. Use a specialized mold cleaner.

Spray concentration:Dilute strictly according to the ratio recommended by the supplier (water-based, solvent-based). A concentration that is too high can lead to residue, scaling, and surface defects; too low a concentration results in poor demolding effects.Follow the principle of "small amounts, multiple times."

3. Spraying method:

Uniformity above all:Use a spray gun to ensure good atomization and cover all surfaces that require mold release (especially cavities, cores, sliders, and ejector pins), avoiding buildup or missed spots.

Distance and Angle:Maintain an appropriate distance (usually 20-50 cm) and angle to avoid direct impact that may cause the solution to splash or be blown away.

Automated sprayingFor complex molds or large-scale production, it is recommended to use an automatic spraying system to ensure consistency and efficiency.

4. Drying/Curing:

Solvent-based:Wait for the solvent to evaporate completely (usually a few seconds to several tens of seconds), and confirm that the mold surface is dry and free of liquid before closing the mold and injecting.

Water-based: Must be thoroughly dry!It can be achieved by extending the waiting time, using mold temperature drying, or air-blowing assistance. Incomplete drying will cause surface water marks, air marks, silver streaks, or even sticking to the mold on the product.

Semi-permanent type:After the initial coating, a certain period of time (or heating) is usually required to allow it to crosslink and cure on the mold surface, forming a strong film. Follow the supplier’s instructions.

5. Spraying frequency:

Mold release agent (conventional): Usually sprayed once every mold or every few molds.

Semi-permanent type: Depending on the formulation and process conditions, it can last for dozens to hundreds of demolding cycles. The release effect should be monitored and reapplied in a timely manner when performance declines.

6. Dosage control:To ensure smooth demolding,Minimize usageOveruse is the main cause of residues, buildup, and surface issues.

7. Environmental Control:Ensure good ventilation in the spraying area (especially when using solvent-based products).

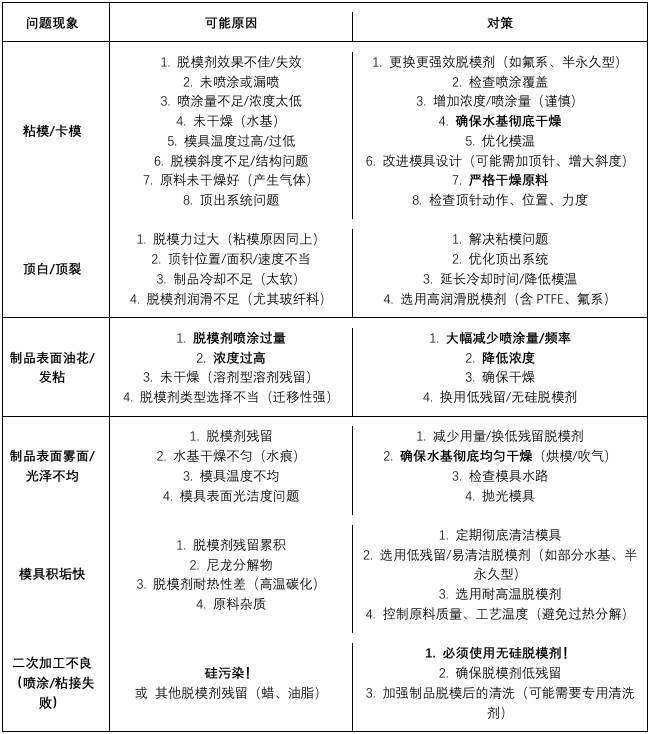

VII. Common Problems and Countermeasures

Environmental protection:The performance of water-based release agents continues to improve (approaching the effectiveness of solvent-based agents), while the development of solvent-free technologies and bio-based release agents is accelerating.

High performance:Semi-permanent fluorine-based release agents are more widely used, with a pursuit for longer-lasting effects, lower residue, higher heat resistance, and stronger release performance.

Customization:Provide customized formulations for specific nylon grades (such as high-temperature nylon PPA, long-chain nylon PA12), specific products (thin-walled, complex structures, high gloss), and specific processes (high-speed injection molding, micro-foaming).

Intelligent Applications:Combine sensors and automatic control systems to achieve precise dosing, automatic spraying, and effect monitoring of mold release agents.

Multifunctionalization:Release agents also have functions such as rust prevention, mold cleaning, and improving the surface gloss of products.

8. Development Trends

9. Conclusion

The selection and application of nylon release agents is a systematic process that requires comprehensive consideration of material characteristics, product requirements, mold conditions, production processes, environmental safety, and cost-effectiveness.Silicone-free release agentIt requires subsequent processes such as spraying and bonding.Rigid demand。Semi-permanent release agentIt has significant advantages in complex, difficult-to-demold products and production lines that pursue high efficiency.Water-based release agentIt is the general trend of environmental protection, butThoroughly dryIt is crucial. Regardless of which type is chosen,Proper mold cleaning, precise spray control (concentration, uniformity, dosage), and thorough drying.It is the foundation for ensuring demolding effectiveness and product quality. It is recommended to work closely with professional mold release agent suppliers to conduct testing and selection.

I hope this information can provide you with practical reference! If you need a more in-depth discussion on specific application scenarios (such as automotive nylon parts, electronic connectors, glass fiber reinforced nylon gears, etc.), please feel free to communicate further.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track